A cubic light calcium carbonate filler composition and its preparation method and application

A light calcium carbonate, cube technology, applied in the field of papermaking fillers, can solve the problems of AKD affinity impairing the sizing effect, affecting the filler, impairing the sizing and paper strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

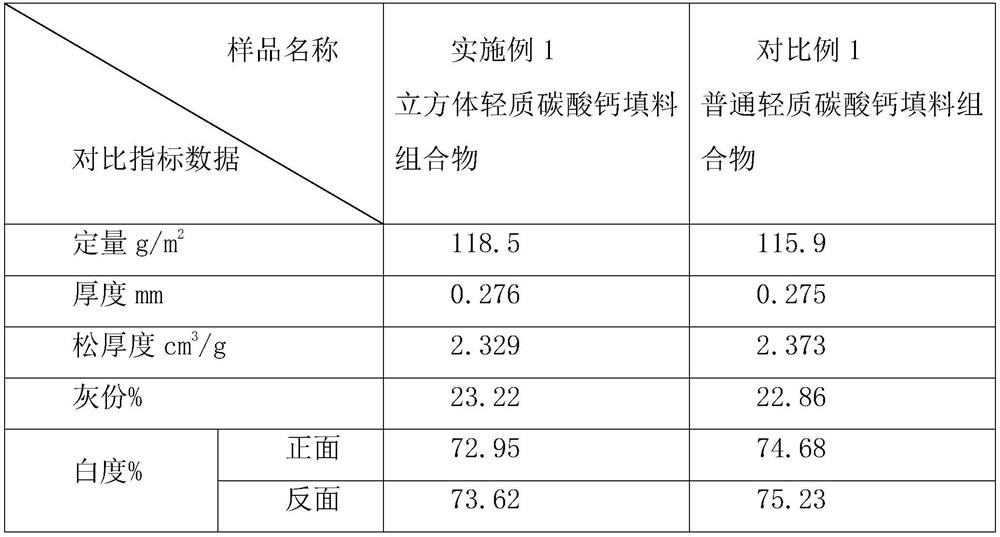

Embodiment 1

[0030] Preparation of the cubic light calcium carbonate filler composition: add the cubic light calcium carbonate filler into the reaction kettle, stir and heat to 60°C. Add 0.25 part of solution-type cationic starch with a concentration of 3% into the filler, stir evenly, and keep warm for 30 minutes. Water was added to adjust the solids content of the filler composition to 18%.

[0031] The application method of cubic light calcium carbonate filler composition (the filler composition is prepared according to the above method by using ordinary light calcium filler and the application comparison is carried out according to the following method):

[0032] Pulp ratio: coniferous pulp (400SR): hardwood pulp (350SR): chemical-mechanical pulp = 25:17:58

[0033] Mixing degree of beating: 350SR, wet weight 0.4g

[0034] Quantitative copying: 120g / m 2

[0035] Papermaking process: pulp (70%) + AKD (20Kg / t paper) + filler composition (30%) + CPAM (300ppm);

[0036] According to t...

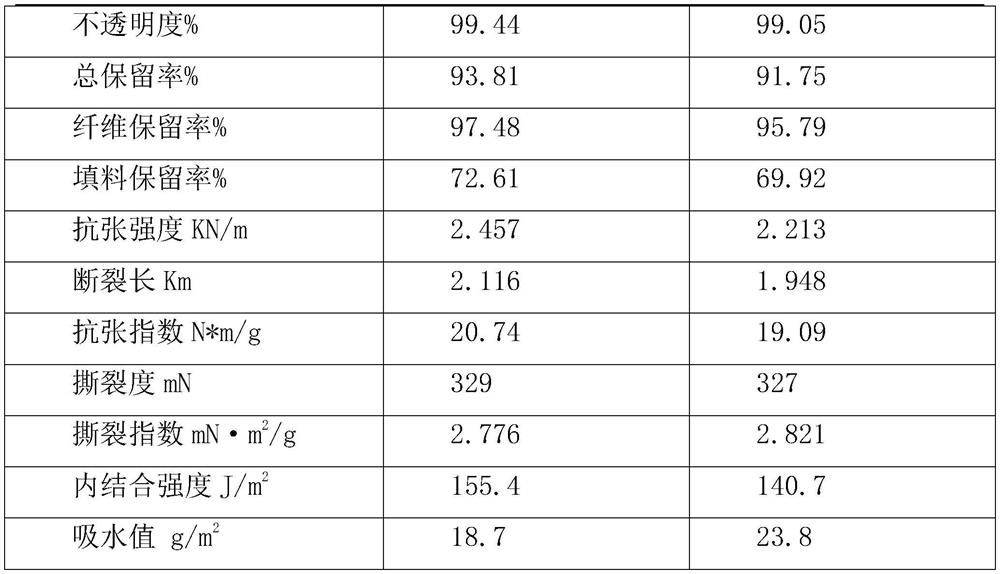

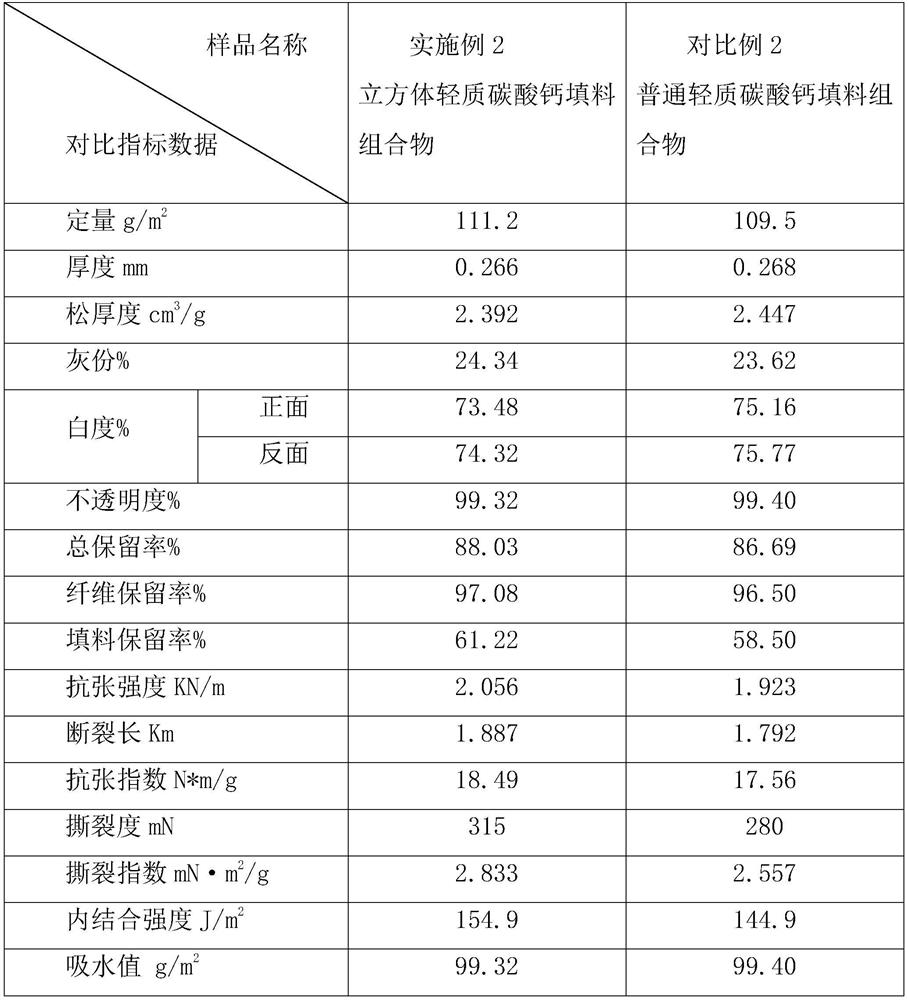

Embodiment 2

[0042] Preparation of the cubic light calcium carbonate filler composition: add the cubic light calcium carbonate filler into the reaction kettle, stir and heat to 60°C. Add 0.25 part of solution-type cationic starch with a concentration of 3% into the filler, stir evenly, and keep warm for 30 minutes. Water was added to adjust the solids content of the filler composition to 18%.

[0043] The application method of cubic light calcium carbonate filler composition (the filler composition is prepared according to the above method by using ordinary light calcium filler and the application comparison is carried out according to the following method):

[0044]Pulp ratio: coniferous pulp (400SR): hardwood pulp (350SR): chemical-mechanical pulp = 25:17:58

[0045] Mixing degree of beating: 350SR, wet weight 0.4g

[0046] Quantitative copying: 120g / m 2

[0047] Papermaking process: pulp (65%) + AKD (20Kg / t paper) + filler composition (35%) + CPAM (300ppm);

[0048] According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com