Trehalose bread and preparation method thereof

A production method, the technology of trehalose, is applied in the direction of dough processing, baking, baked food with modified ingredients, etc. It can solve the problems of high hardness and poor taste, so as to promote blood circulation, improve the body's immunity, and change the body's The effect of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

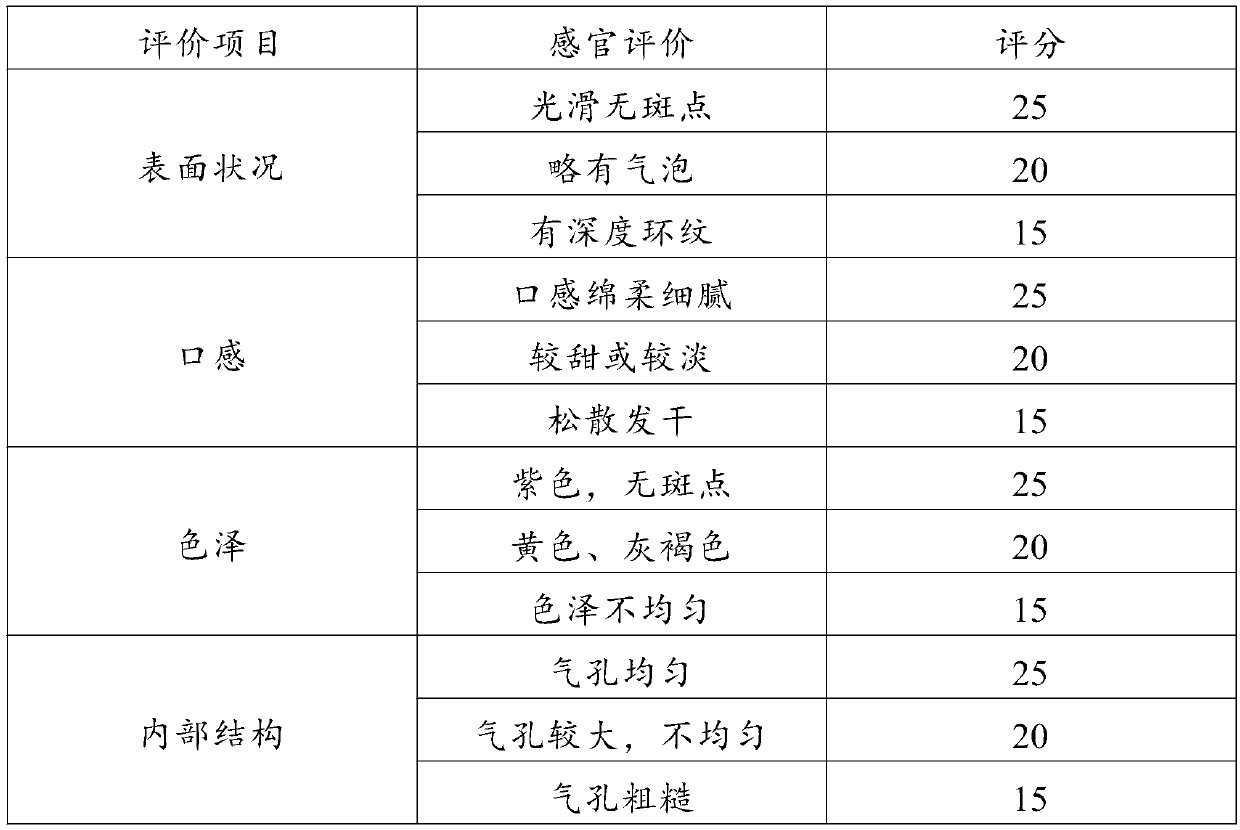

Examples

Embodiment 1

[0027] A kind of trehalose bread is made from the following raw materials in parts by weight:

[0028] 70 parts of high-gluten flour, 30 parts of corn flour, 30 parts of purple rice flour, 60 parts of eggs, 8 parts of butter, 1 part of yeast, 2 parts of citric acid, 10 parts of trehalose, 5 parts of crystalline fructose and 5 parts of corn maltodextrin.

[0029] The preparation method of above-mentioned trehalose bread comprises the following steps:

[0030] S1: Put the yeast in purified water at 38°C-42°C, and let it stand for 40 minutes to activate the yeast to obtain a yeast emulsion;

[0031] S2: Remove high-gluten flour, corn flour, eggs and butter, add yeast emulsion, mix well and knead to get dough, once;

[0032] S3: mixing citric acid, trehalose and crystalline fructose with water to obtain a mixed solution;

[0033] S4: Add the mixed solution and purple rice flour to the dough, and knead the dough again;

[0034] S5: Fermenting the dough prepared in S4 at a temper...

Embodiment 2

[0040] A kind of trehalose bread is made from the following raw materials in parts by weight:

[0041] 75 parts of high-gluten flour, 40 parts of corn flour, 35 parts of purple rice flour, 65 parts of eggs, 12 parts of butter, 2 parts of yeast, 3 parts of citric acid, 25 parts of trehalose, 8 parts of crystalline fructose and 7 parts of corn maltodextrin.

[0042] The preparation method of above-mentioned trehalose bread comprises the following steps:

[0043] S1: Put the yeast in purified water at 38°C-42°C, and let it stand for 40 minutes to activate the yeast to obtain a yeast emulsion;

[0044] S2: Remove high-gluten flour, corn flour, eggs and butter, add yeast emulsion, mix well and knead to get dough, once;

[0045] S3: mixing citric acid, trehalose and crystalline fructose with water to obtain a mixed solution;

[0046] S4: Add the mixed solution and purple rice flour to the dough, and knead the dough again;

[0047] S5: Fermenting the dough prepared in S4 at a temp...

Embodiment 3

[0053] A kind of trehalose bread is made from the following raw materials in parts by weight:

[0054] 70 parts of high-gluten flour, 35 parts of corn flour, 30 parts of purple rice flour, 60 parts of eggs, 10 parts of butter, 2 parts of yeast, 3 parts of citric acid, 20 parts of trehalose, 6 parts of crystalline fructose and 6 parts of corn maltodextrin.

[0055] The preparation method of above-mentioned trehalose bread comprises the following steps:

[0056] S1: Put the yeast in purified water at 38°C-42°C, and let it stand for 40 minutes to activate the yeast to obtain a yeast emulsion;

[0057] S2: Remove high-gluten flour, corn flour, eggs and butter, add yeast emulsion, mix well and knead to get dough, once;

[0058] S3: mixing citric acid, trehalose and crystalline fructose with water to obtain a mixed solution;

[0059] S4: Add the mixed solution and purple rice flour to the dough, and knead the dough again;

[0060] S5: Fermenting the dough prepared in S4 at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com