Functional fried rice noodles and preparation method thereof

A technology for functional, pho, which is applied in the field of preparing functional pho rich in slow-digesting and anti-digestible starch, can solve the problems of uneven distribution, ineffective synergistic strengthening effect of texture improvement and nutritional properties of pho, etc., To achieve the effect of simple processing equipment, convenient industrial production and processing, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

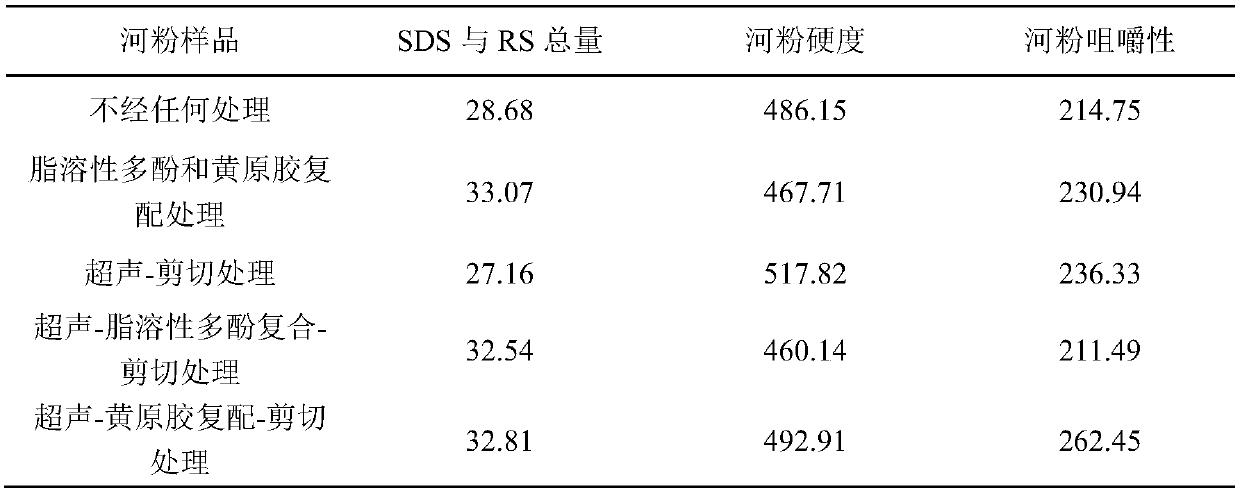

[0025] Accurately weigh a certain amount of carp indica rice in Fulinmen water, and add water to control the indica rice quality to account for 35% of the total mass. After soaking for 12 hours, fully refine the pulp, and carry out ultrasonic treatment with an output power of 200W and a duration of 20min, add xanthan gum with a dry basis of indica rice flour of 2.5‰, lauryl gallate of 5‰ (first use 10 times of lauryl gallate Edible alcohol of ester quality is dissolved, and then fully mixed with the slurry), applied high-speed shear (speed: 2000rpm, time: 5min) and fully mixed. The obtained slurry was placed on a shallow pan of a rice steamer, steamed in steam at 100°C for 3 minutes, cooled at room temperature and placed in water for further coagulation for 4 minutes; after cooling, it was cut into strips to prepare functional river noodles. At the same time, without any treatment, fat-soluble polyphenol and xanthan gum compound treatment, ultrasonic-shearing treatment, ultras...

Embodiment 2

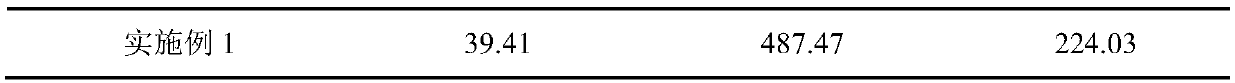

[0032]Accurately weigh a certain amount of Fulinmen oil sticky rice, add water to control the mass of indica rice to account for 38% of the total mass. After soaking for 10 hours, fully refine the pulp, and carry out ultrasonic treatment with an output power of 300W and a duration of 15min, add xanthan gum of 5‰ dry weight of indica rice flour, 10‰ lauryl gallate (first use 10 times lauryl gallate Edible alcohol of ester quality is dissolved, and then fully mixed with the slurry), applied high-speed shear (speed: 3000rpm, time: 6min) and fully mixed. The obtained slurry was placed on a shallow pan of a rice steamer, steamed in steam at 100°C for 5 minutes, cooled at room temperature and placed in water for further coagulation for 3 minutes; after cooling, it was cut into strips to prepare functional river noodles. At the same time, without any treatment, fat-soluble polyphenol and xanthan gum compound treatment, ultrasonic-shearing treatment, ultrasonic-fat-soluble polyphenol ...

Embodiment 3

[0038] Accurately weigh a certain amount of Tailiang Mingxiang Zungui indica rice, and add water to control the indica rice quality to account for 33% of the total mass. After soaking for 8 hours, fully refine the pulp, and carry out ultrasonic treatment with an output power of 100W and a duration of 30min, add xanthan gum with a dry basis of indica rice flour of 2.5‰, propyl gallate of 5‰ (first use 10 times propyl gallate Edible alcohol of ester quality is dissolved, and then fully mixed with the slurry), applying high-speed shear (speed: 2500rpm, time: 7min) and fully mixed. The obtained slurry was placed on a shallow pan of a rice steamer, steamed in steam at 100°C for 6 minutes, cooled at room temperature and placed in water for further coagulation for 5 minutes; after cooling, it was cut into strips to prepare functional river noodles. At the same time, without any treatment, fat-soluble polyphenol and xanthan gum compound treatment, ultrasonic-shearing treatment, ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com