Synthesis method of particle-size-controllable needle-shaped ZSM-5 molecular sieve

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of cumbersome preparation process, long crystallization time, and large environmental pollution. Achieve the effects of reducing environmental pollution, reducing synthesis costs, and avoiding cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Synthesis method: Add 15g of water, 0.051g of aluminum sulfate octadecahydrate, 12g of tetrapropylammonium hydroxide, and 16g of cyclohexylamine into the reaction kettle, and after stirring evenly, slowly add 15g of it drop by drop during the stirring process with a mass fraction of 40% Silica sol, described silica sol is processed by adding 2.3g sodium hydroxide in advance, the average molecular weight D of silica sol recorded by small angle X-ray diffraction method is 12000, and D is divided by repeating unit SiO 2 Calculate the molecular weight of 60, control the degree of silicon polymerization to obtain 200, stir for 30 minutes, and age the gel at room temperature. After that, crystallize at 180°C for 2 days under stirring at 150rpm, after cooling to room temperature, wash and centrifuge with deionized water for 3 times, and dry at 80°C for 12 hours to obtain the final product Z-1.

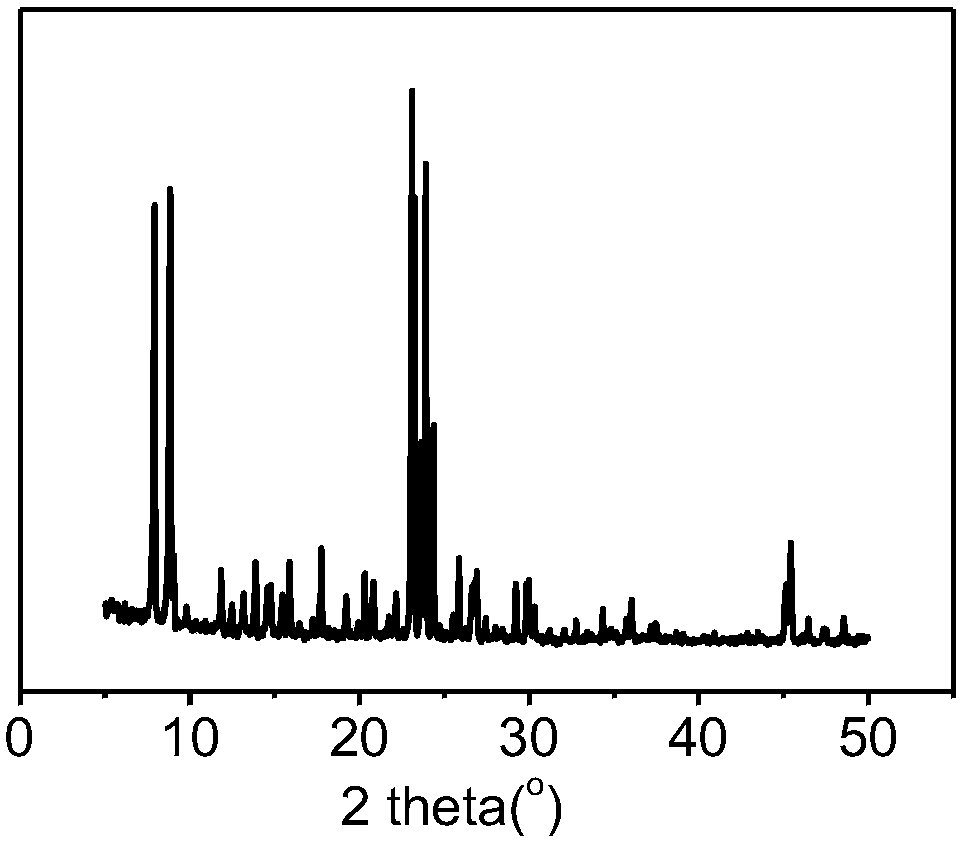

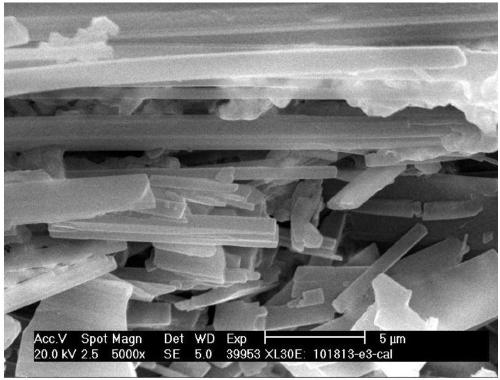

[0030] figure 1 It is the XRD spectrogram of the product obtained in Example 1, i...

Embodiment 2

[0032] Using the same conditions as in Example 1, after stirring evenly, slowly add 6.93g ethyl orthosilicate dropwise during the stirring process, and the ethyl orthosilicate is treated by adding 3g sodium hydroxide in advance to control the degree of silicon polymerization to 80, stirred for 30min, and aged at room temperature. After that, it was crystallized at 180°C and 150rpm for 2 days, cooled to room temperature, washed and centrifuged with deionized water for 3 times, and dried at 80°C for 12 hours to obtain the final product Z-2. According to the XRD characterization results of the sample, it can be seen that the product has the characteristic diffraction peak of ZSM-5, and the SEM photo of the obtained product shows that the sample presents a needle-shaped morphology, and the particle diameter is 100-200 nanometers.

Embodiment 3

[0034] Using the same conditions as in Example 1, after stirring evenly, slowly add 2 g of silicon powder dropwise during the stirring process, and the silicon powder is treated by adding 2.5 sodium hydroxide in advance to control the degree of silicon polymerization to 100, stir for 30 minutes, and Gel aging. After that, it was crystallized at 180°C and 150rpm for 2 days, cooled to room temperature, washed and centrifuged with deionized water for 3 times, and dried at 80°C for 12 hours to obtain the final product Z-3. According to the XRD characterization results of the sample, it can be seen that the product has the characteristic diffraction peak of ZSM-5, and the SEM photos of the obtained product show that the sample presents a needle-like shape, and the particle diameter is 1-2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com