Sound-absorbing ceramic material and preparation method thereof

A ceramic material and sound-absorbing technology, applied in the field of sound-absorbing ceramic materials and their preparation, can solve the problems of limited use environment, poor sound absorption effect, poor fire resistance, etc., and achieve strong protection ability, good moisture resistance and frost resistance, Good sound absorption system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

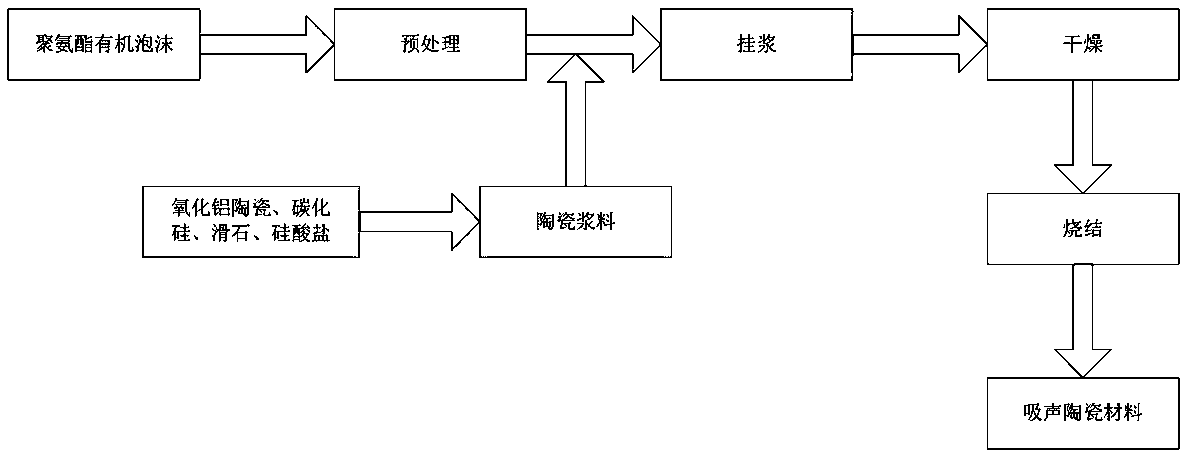

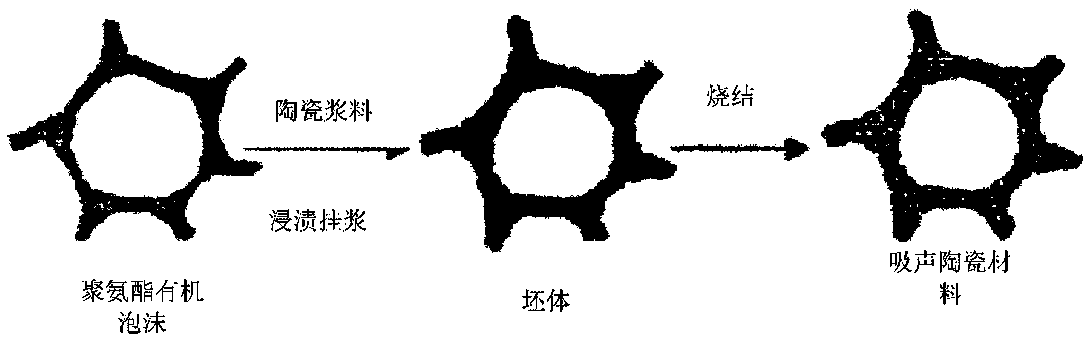

[0045] Such as figure 1 and 2 Shown, a kind of preparation method of sound-absorbing ceramic material of the present invention comprises the following steps:

[0046] S1. After mixing alumina ceramics, silicon carbide, talc and silicate evenly, adding a solvent to obtain a ceramic slurry;

[0047] S2, the polyurethane organic foam is sequentially pretreated with sodium hydroxide solution and carboxymethyl cellulose solution to obtain pretreated polyurethane organic foam;

[0048] S3, immersing the pretreated polyurethane organic foam obtained in step S2 into the ceramic slurry obtained in step S1 to carry out a slurrying step, and drying to obtain a green body;

[0049] S4. Sintering the body obtained in step S3 to obtain a sound-absorbing ceramic material after the sintering is completed.

[0050] The present invention utilizes the polyurethane organic foam which has an open-pore three-dimensional network skeleton and is decomposable at high temperature as a porous carrier...

Embodiment 1

[0052] A preparation method of the sound-absorbing ceramic material of this embodiment, comprising the following steps:

[0053] (1) Mix 30 parts of high-content alumina ceramic powder with 15 parts of dispersant carboxymethyl cellulose and 5 parts of polyethylene oxide, and then mix with 25 parts of silicon carbide powder, 35 parts of talc powder and 15 parts of magnesium silicate powder Fully grind and mix by ball milling to obtain ceramic materials; add 40 parts of water to the ceramic materials and stir for 15 minutes with a constant temperature magnetic stirrer to obtain ceramic slurry. At this time, the ceramic slurry has good fluidity and stability, and water can promote mixing. Material, mixing and other processes are carried out smoothly.

[0054](2) Take 1 part of polyurethane organic foam for pretreatment, first soak it in 2 parts of NaOH solution with a concentration of 25% at 30°C for 18 hours, take it out, rinse it with clean water, dry it naturally in the air, a...

Embodiment 2

[0061] A preparation method of the sound-absorbing ceramic material of this embodiment, comprising the following steps:

[0062] (1) Mix 25 parts of high-content alumina ceramic powder, 10 parts of dispersant carboxymethyl cellulose, and 2 parts of polyethylene oxide, and then mix with 25 parts of silicon carbide powder, 25 parts of talc powder and 10 parts of potassium silicate powder Fully grind and mix by ball milling to obtain ceramic materials; add 30 parts of water to the ceramic materials, and stir with a constant temperature magnetic stirrer for 15 minutes to obtain ceramic slurry. At this time, the ceramic slurry has good fluidity and stability, and water can promote mixing. Material, mixing and other processes are carried out smoothly.

[0063] (2) Take 1 part of polyurethane organic foam for pretreatment, first soak it in 3 parts of 20% NaOH solution at 30°C for 12 hours, take it out, rinse it with clean water, dry it naturally in the air, and then put it in 4 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com