A special material for injection molding urea tank and its preparation method

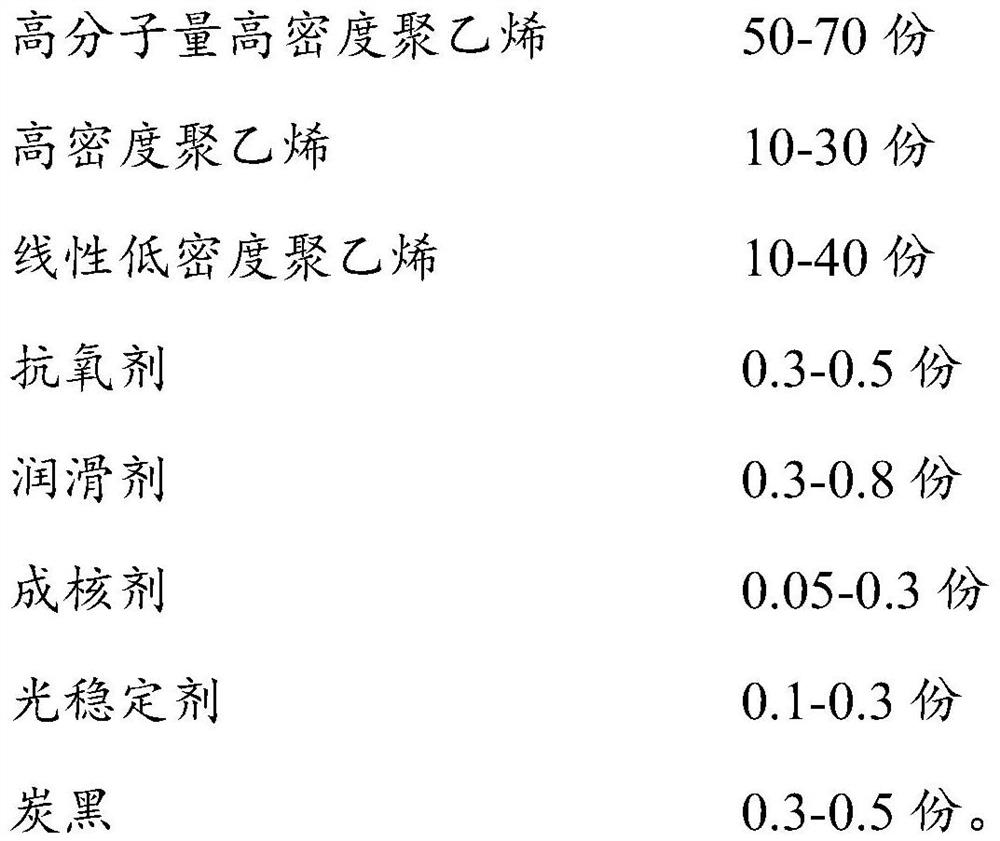

A special material and urea tank technology, which is applied in the field of injection molding urea tank special material and its preparation, can solve the problems of accelerated catalytic polyethylene oxidative degradation reaction, low melting index of high-density polyethylene, performance degradation of urea tank products, etc. Environmental stress cracking performance, accelerated crystallization rate, and improved UV aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objects, technical solutions, and advantages of the present invention, the technical solution will be described in conjunction with the embodiment of the present invention. Embodiments. Based on the embodiments in the present invention, all other embodiments obtained without creative labor are not made in the premise of creative labor.

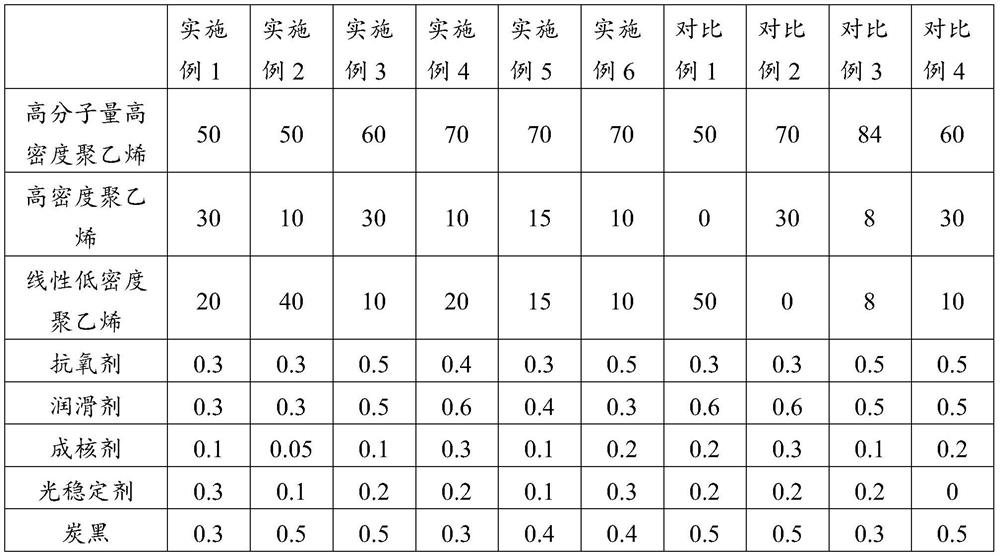

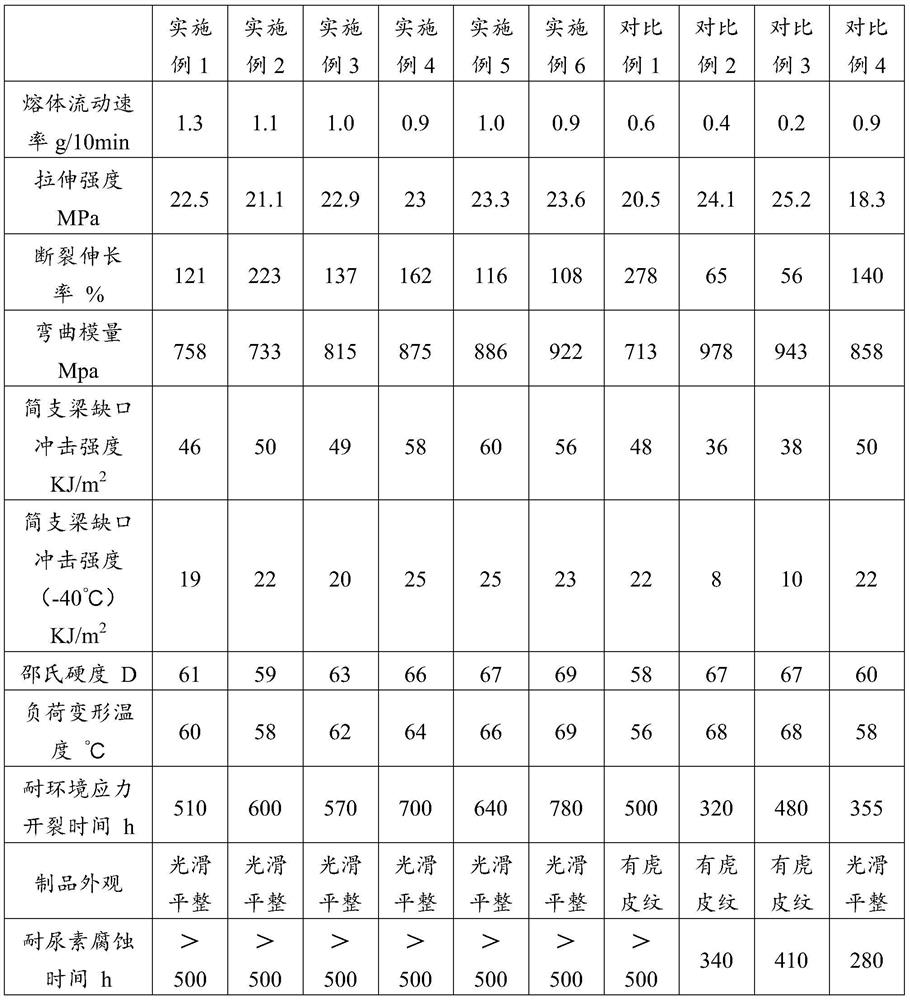

[0022] The present invention provides Examples 1-6 and Comparative Example 1-4.

[0023] Table 1: Embodiments and comparative materials composition and ratio

[0024]

[0025] Among them, preferably, high molecular weight high density polyethylene is used to use a melt index of from 0.04 to 0.2 g / 10 min (2.16 kg / 190 ° C), with a weight average molecular weight of 20-500,000, tensile and yield strength ≥ 25 MPa, simple beam disadgice impact Strength ≥90kj / m 2 .

[0026] Preferably, the high density polyethylene is selected from 1 to 4 g / 10 min (2.16 kg / 190 ° C), and the tensile yield strength ≥ 20 MPa.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com