A kind of surface non-adhesive matte soft TPU and preparation method thereof

A matte and soft technology, applied in the field of polymer materials, can solve the problems of reducing surface adhesion, frosting, migration and precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the embodiment of the present invention is as follows:

[0049] Step 1: Weighing thermoplastic polyurethane elastomer TPU, matting agent, compatibilizer, antisticking agent and antioxidant according to parts by weight;

[0050] Step 2: premixing the above-mentioned raw materials to obtain a premix;

[0051] Step 3: Put the premix into the twin-screw extruder to melt and extrude;

[0052] Step 4: Cutting and granulating the extruded product to obtain a non-adhesive matte soft TPU on the surface.

[0053] The technological parameter of twin-screw extruder in described step 3 is as follows:

[0054] Screw speed: 300RPM

[0055] Main feeding rate: 200RPM

[0056] One section of screw temperature: 150±5℃

[0057] Two-section screw temperature: 160±5℃

[0058] Three-section to seven-section screw temperature: 170±5℃

[0059] Eight-section screw temperature: 175±5℃

[0060] Nine-section screw temperature: 175±5°C

[0061] Ten-section screw te...

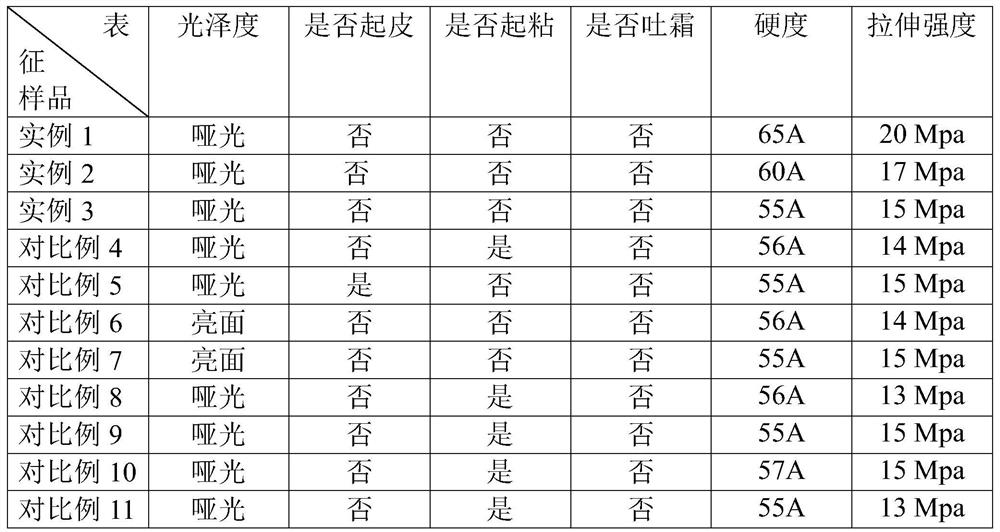

Embodiment 1-3

[0068] The raw materials involved in Examples 1-3 are: the thermoplastic polyelastomer TPU is TPU manufactured by Huafon, the matting agent is Kraton SEBS1651, and the compatibilizer is hydrogenated styrene-butadiene-styrene block copolymer Grafted maleic anhydride polymer, grade Kraton 1901, antioxidant type Irganox 1010, anti-adhesive agent 2-trimethylsiloxy-4-allyloxydiphenyl ketone, methyl trimethyl A mixture of silyldimethylketene acetal, 2,3,3,3-tetrafluoro-1-propene, 2-acrylic acid-2-carboxyethyl ester.

[0069] in

Embodiment 1

[0070] In Example 1, 2-trimethylsilyloxy-4-allyloxydiphenylketone, methyltrimethylsilyldimethylketene acetal, 2,3,3,3-tetrafluoro -1-propylene, 2-acrylic acid-2-carboxyethyl ester mass ratio is 1:1.2:2:0.8; thermoplastic polyelastomer TPU is Huafeng TPU HF-S1065APU-1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com