Shale intercalation inhibitor prepared from hyperbranched quaternary ammonium salt

A hyperbranched quaternary ammonium salt and inhibitor technology, which is applied in the field of oil and gas field drilling, can solve problems such as clay entanglement, uneven coating, limitation of inhibition performance, repeated adsorption, etc., and achieve enhanced water solubility, improved inhibition performance, and good inhibition effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The hyperbranched quaternary ammonium salt was prepared with diethylenetriamine and divinyl sulfone as raw materials, and trimethylallylammonium as a capping reagent.

[0028] (1) Preliminary synthesis

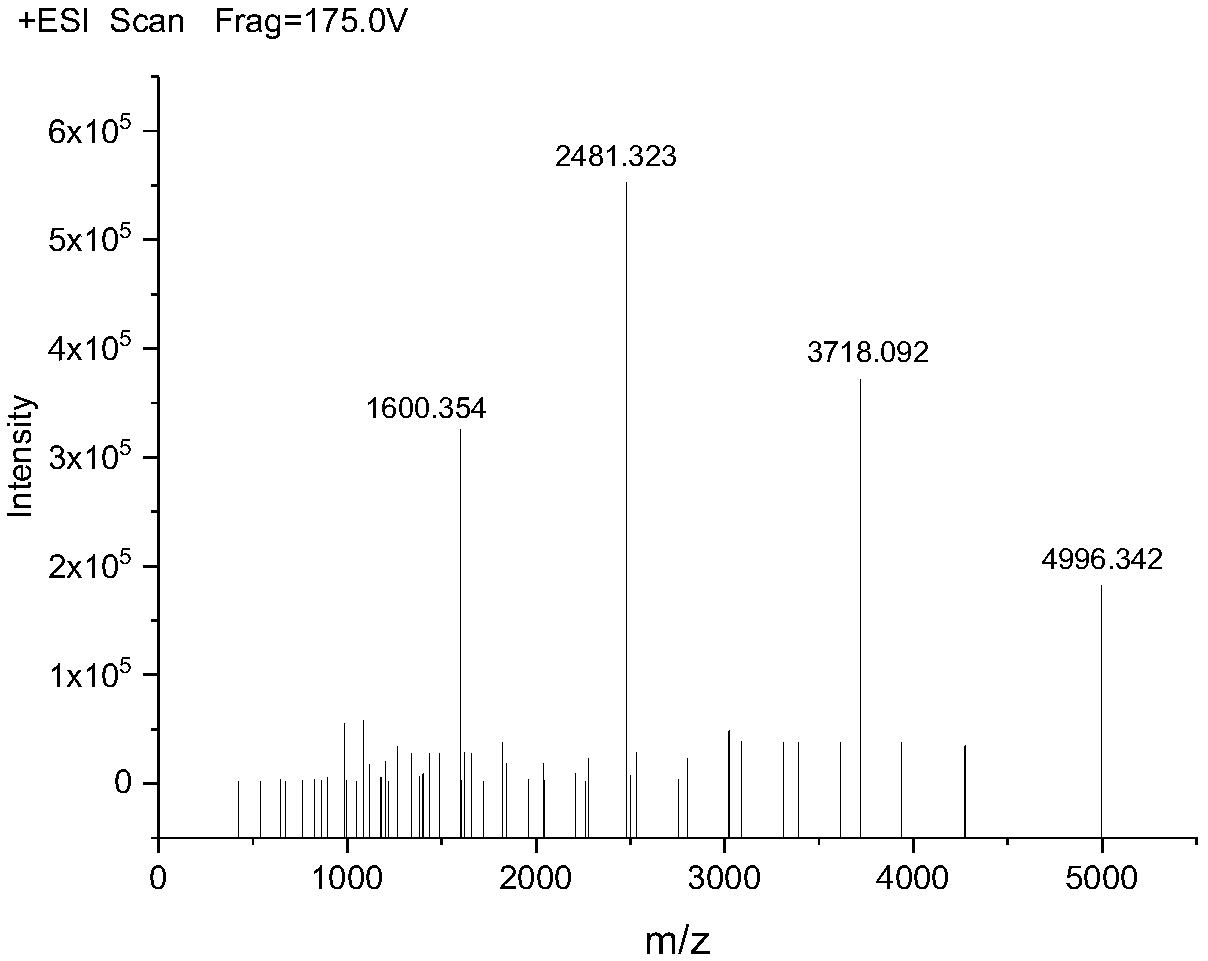

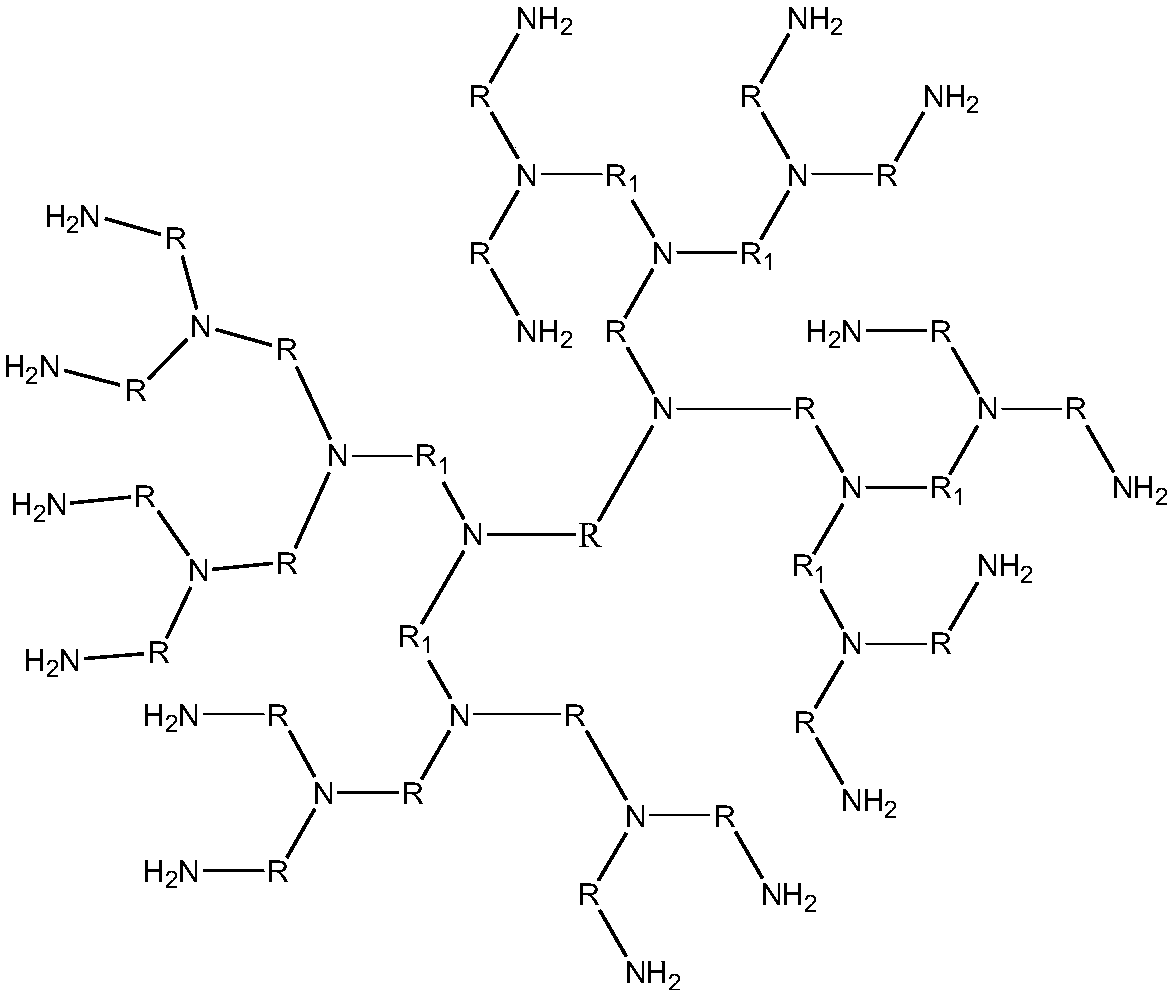

[0029] Dissolve diethylene triamine and divinyl sulfone with a molar ratio of 1 / 1 in 100 mL of DMSO, of which diethylene triamine is 5.6 g, and add the DMSO solution of divinyl sulfone to a 500 mL three-necked flask. Under the condition of nitrogen gas and stirring, the DMSO solution of diethylenetriamine was dropped into a three-necked flask for 30 minutes, and the reaction was stirred for 36 hours at room temperature. After the reaction is completed, rotary evaporation is performed at 120° C. and an absolute vacuum degree of less than 3000 Pa to obtain a viscous product A1. The structural formula is shown in the figure below, which is an ideal, fully branched hyperbranched polymer.

[0030]

[0031] Among them, R=-CH 2 CH 2 SO 2 CH 2 CH 2 -; R 1 =-CH 2 CH 2 -.

[0032] (2) ...

Embodiment 2

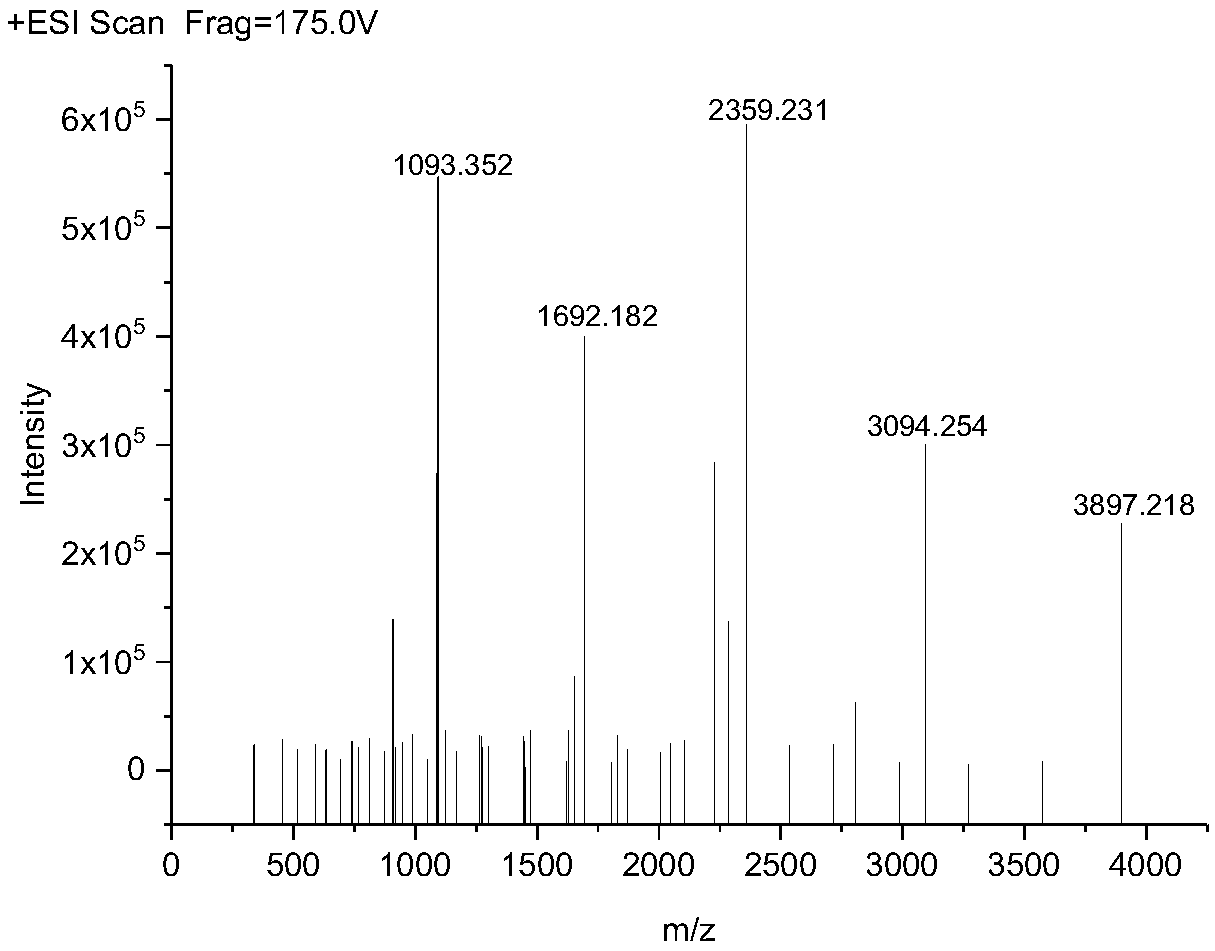

[0038] Preparation of hyperbranched quaternary ammonium salt using ethylenediamine and divinyl sulfone as raw materials and trimethylallyl ammonium as capping reagent

[0039] (1) Preliminary synthesis

[0040] Dissolve ethylene diamine and divinyl sulfone in 100 mL of DMSO at a molar ratio of 1:1, of which ethylene diamine is 3.0 g. Add the DMSO solution of divinyl sulfone to a 500 mL three-necked flask, and blow nitrogen through it. While stirring, the DMSO solution of diethylenetriamine was dropped into a three-necked flask for 30 minutes, and the reaction was stirred at room temperature for 36 hours. After the reaction is completed, rotary evaporation is performed at 120° C. and an absolute vacuum degree of less than 3000 Pa to obtain a viscous product A2. The structural formula is shown in the figure below, which is an ideal, fully branched hyperbranched polymer.

[0041]

[0042] Among them, R=-CH 2 CH 2 SO 2 CH 2 CH 2 NHCH 2 CH 2 -.

[0043] (2) End-capping modification

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com