Nickel matte preparation method

A technology for nickel matte and matte furnace, which is applied in the field of nickel matte preparation, can solve the problems of high power dependence, high cost, difficulty in large-scale production, etc., and achieves the effects of improving smelting efficiency, reducing energy consumption and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

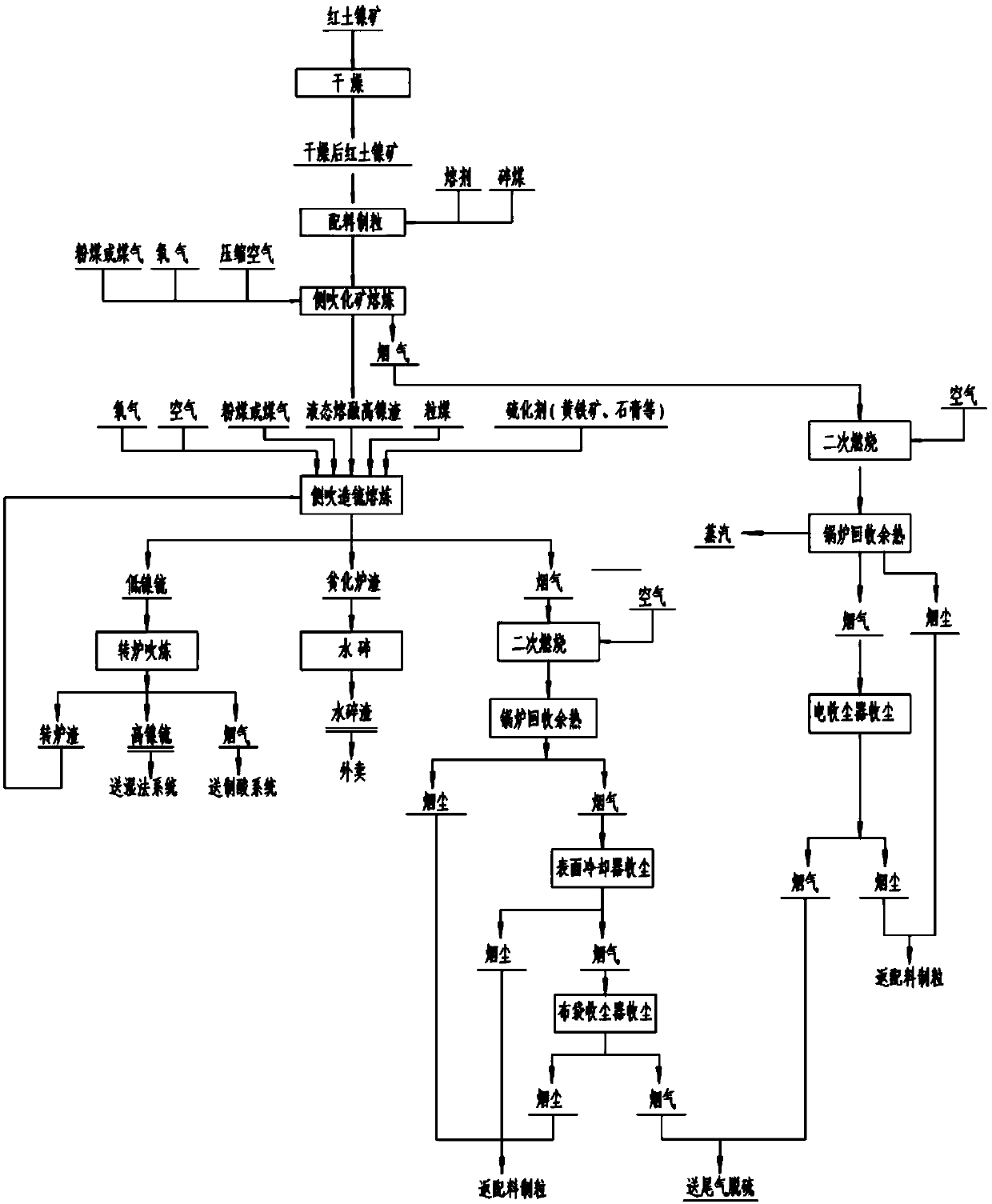

[0023] figure 1 Be the process flow sheet of the preparation nickel matte of one embodiment of the present invention, as figure 1 As shown, when using laterite nickel ore and / or nickel-containing waste slag to prepare nickel matte, the laterite nickel ore and / or nickel-containing waste slag are first dried at about 200°C in a drying kiln to remove part of the free water. The dried lateritic nickel ore and / or nickel-containing waste, reduced coal (crushed coal), flux and circulating smelting dust are batched and granulated through the disc granulator equipped in the plant to obtain nickel-containing materials.

[0024] The nickel-containing material is sent to the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com