Preparation method of collagen fibers

A collagen fiber, collagen technology, applied in the direction of fiber chemical characteristics, single-component protein rayon, textiles and paper making, etc., can solve the problems of reducing practical application, easily destroying the activity of collagen, and achieving no damage to the structure, independent High sex, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

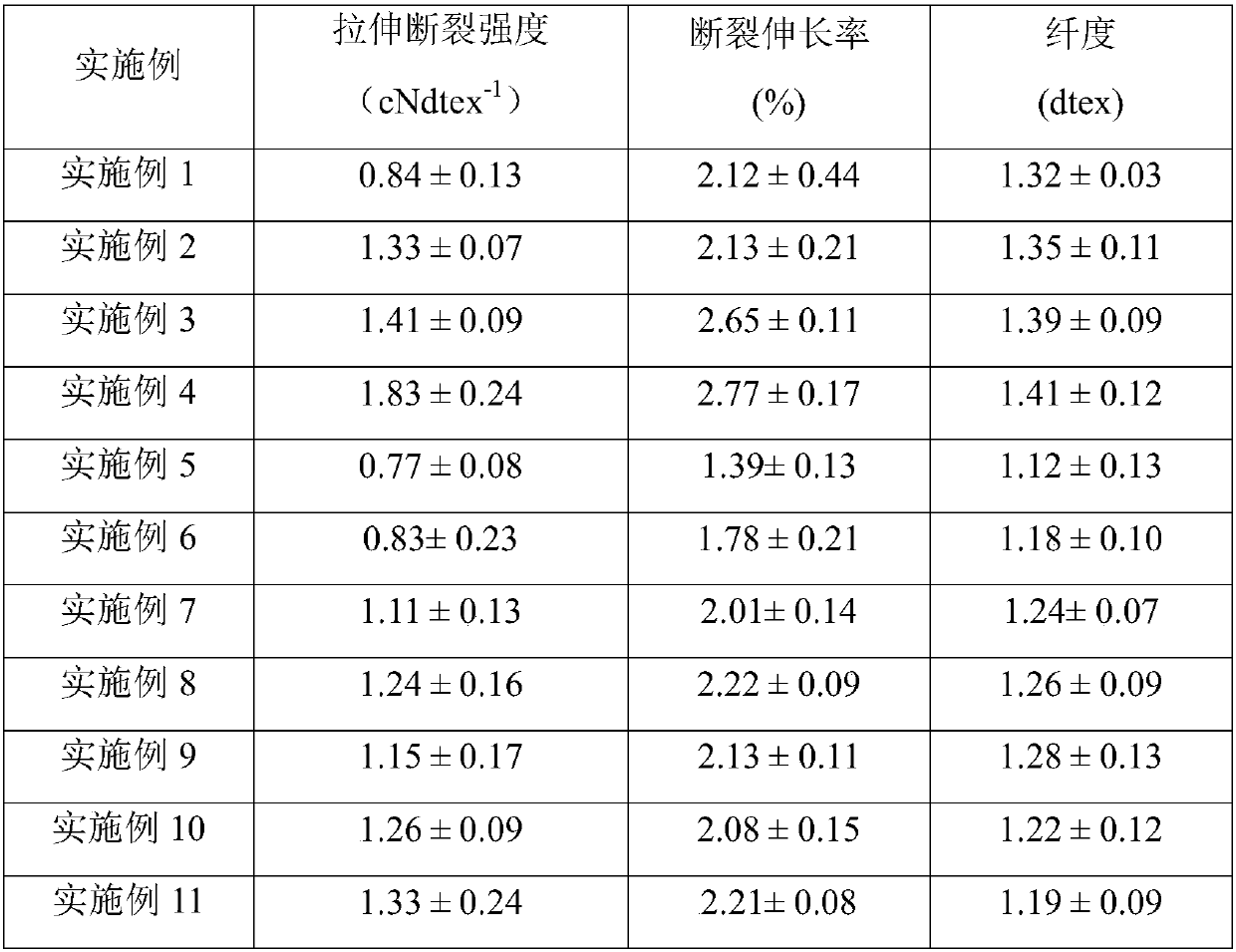

Embodiment 1

[0040] 5g collagen is dissolved in 200g chloride N-butyl-N-methyldiethanolamine ionic liquid aqueous solution (the concentration of ionic liquid is 0.04wt%), and the pH of adjustment solution is 3, injects after centrifugal defoaming of collagen solution In the storage tank of the spinning machine, under the pressure of 0.1MPa, the spinning solution is sprayed from the spinneret to the first coagulation bath containing 20L ethanol (concentration is 90%) by the metering pump, and the spinneret The pore size is 70 μm, and the speed at which the collagen solution is ejected from the spinneret is 10 m / min. The collagen solution is immediately dehydrated and solidified into a fibrous shape, and the drafting speed in the first coagulation tank is 20 m / min; The collagen fiber that a coagulation bath comes out enters in the 2nd coagulation bath (ethanol 20L, concentration is 99.5%) by drafting, further dehydration under room temperature, the collagen fiber that comes out from the 2nd c...

Embodiment 2

[0042]10g of collagen is dissolved in 200g of N-hexyl-N-methyldiethanolamine chloride ionic liquid aqueous solution (concentration is 0.08wt%), and the pH of the control solution is 3, and the collagen solution is centrifugally defoamed and injected into the spinning In the storage tank of the machine, under the pressure of 0.1MPa, the spinning solution is sprayed from the spinneret to the first coagulation tank containing 20L ethanol (concentration is 90%) through the metering pump, and the aperture of the spinneret is 100 μm, the speed at which the collagen solution is ejected from the spinneret is 15m / min, and the collagen solution is immediately dehydrated and solidified into a fibrous shape, and the drafting speed in the first coagulation tank is 25m / min. The collagen fibers coming out of the first coagulation bath are drawn into the second coagulation bath (20 L of ethanol, the concentration is 99.5%), and further dehydrated at room temperature. Collagen fibers coming ou...

Embodiment 3

[0044] 16g of collagen is dissolved in 200g of N-butyl-N-methyldiethanolamine chloride ionic liquid (concentration is 0.4wt%), the pH of the control solution is 4, and the collagen solution is centrifugally defoamed and injected into the spinning In the storage tank of the machine, under the pressure of 0.1MPa, the spinning solution is sprayed from the spinneret to the first coagulation tank containing 20L ethanol (concentration is 90%) through the metering pump, and the aperture of the spinneret is 200 μm, the speed at which the collagen solution is ejected from the spinneret is 30m / min, and the collagen solution is immediately dehydrated and solidified into a fibrous shape, and the drafting speed in the first coagulation tank is 50m / min. The collagen fibers coming out of the first coagulation bath are drawn into the second coagulation bath (20 L of ethanol, the concentration is 99.5%), and further dehydrated at room temperature. Collagen fibers coming out of the second coagu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com