Ultrasonic laser excitation and detection system and method for achieving ultrasonic rapid scanning and fixed-point focusing

A laser ultrasonic and fast scanning technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low efficiency, low precision, excitation effect, signal strength and limited detection rate, etc., to improve the strength and flaw detection accuracy, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

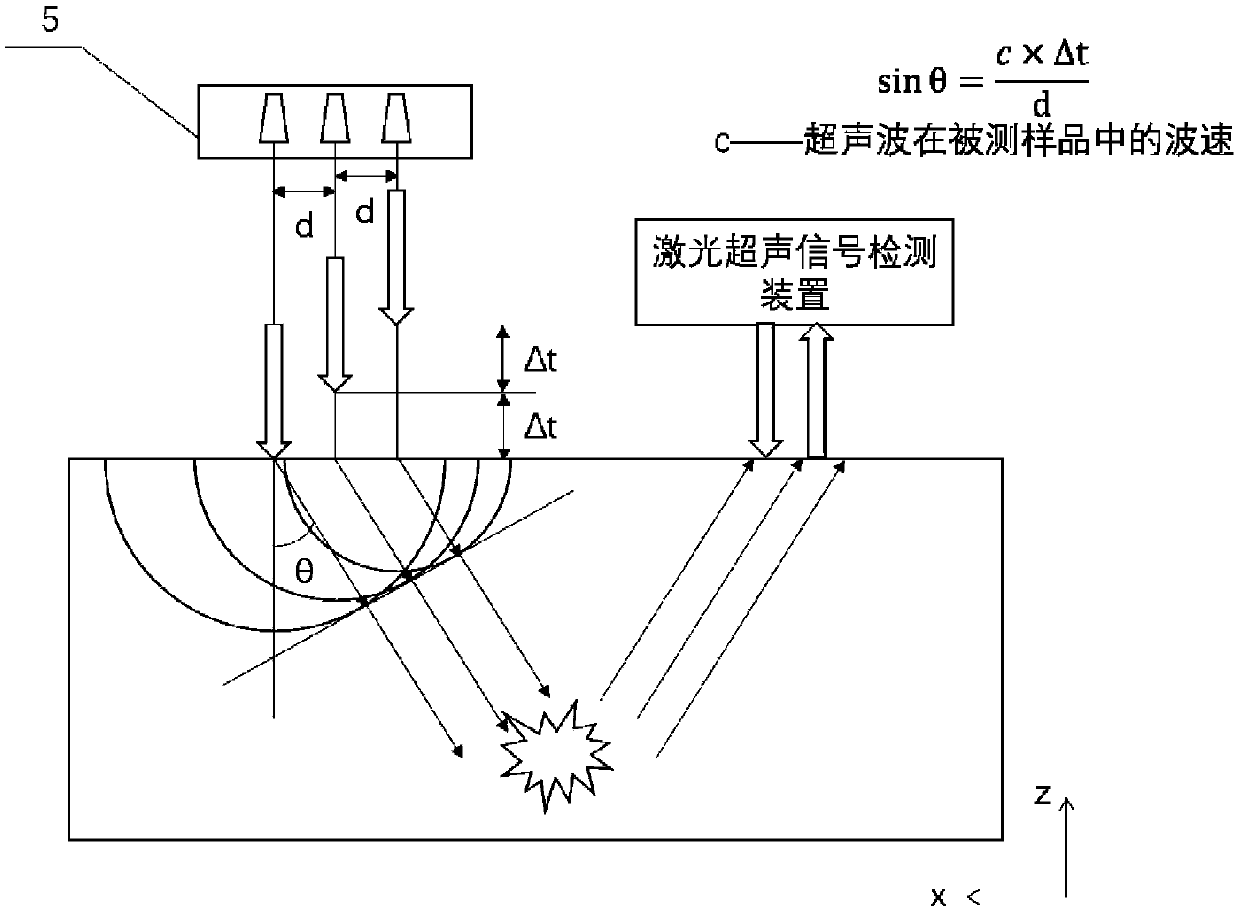

[0050] Such as Figure 1-3 As shown, a laser ultrasonic excitation and detection system of the present invention realizes ultrasonic fast scanning and fixed-point focusing. Signal detection device, signal processing circuit, oscilloscope, computer, stepper motor and electronically controlled displacement table 6; the present invention can realize the rapid scanning of ultrasonic signals on the tested sample and fixed-point focusing on the tested features to obtain clear features Morphological features.

[0051] First, in the rapid scanning stage of the system for the sample to be tested, the pulsed laser 1 emits a beam of pulsed laser light, which is focused by the convex lens 2 and then incident on the optical coupler 3. The optical fiber coupler 3 is connected to a linear array The input end of the optical fiber array 4, the output end of the optical fiber array 4 will vertically emit the linear laser spot of the array; as figure 2 As shown, because the lengths of the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com