Large-cavity high-temperature high-pressure gas-liquid two-phase flow experimental device and experimental method thereof

An experimental device, high-pressure gas technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of reduced luminous flux, difficult sample cavity volume, high diamond density, etc., and achieve the effect of increased functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

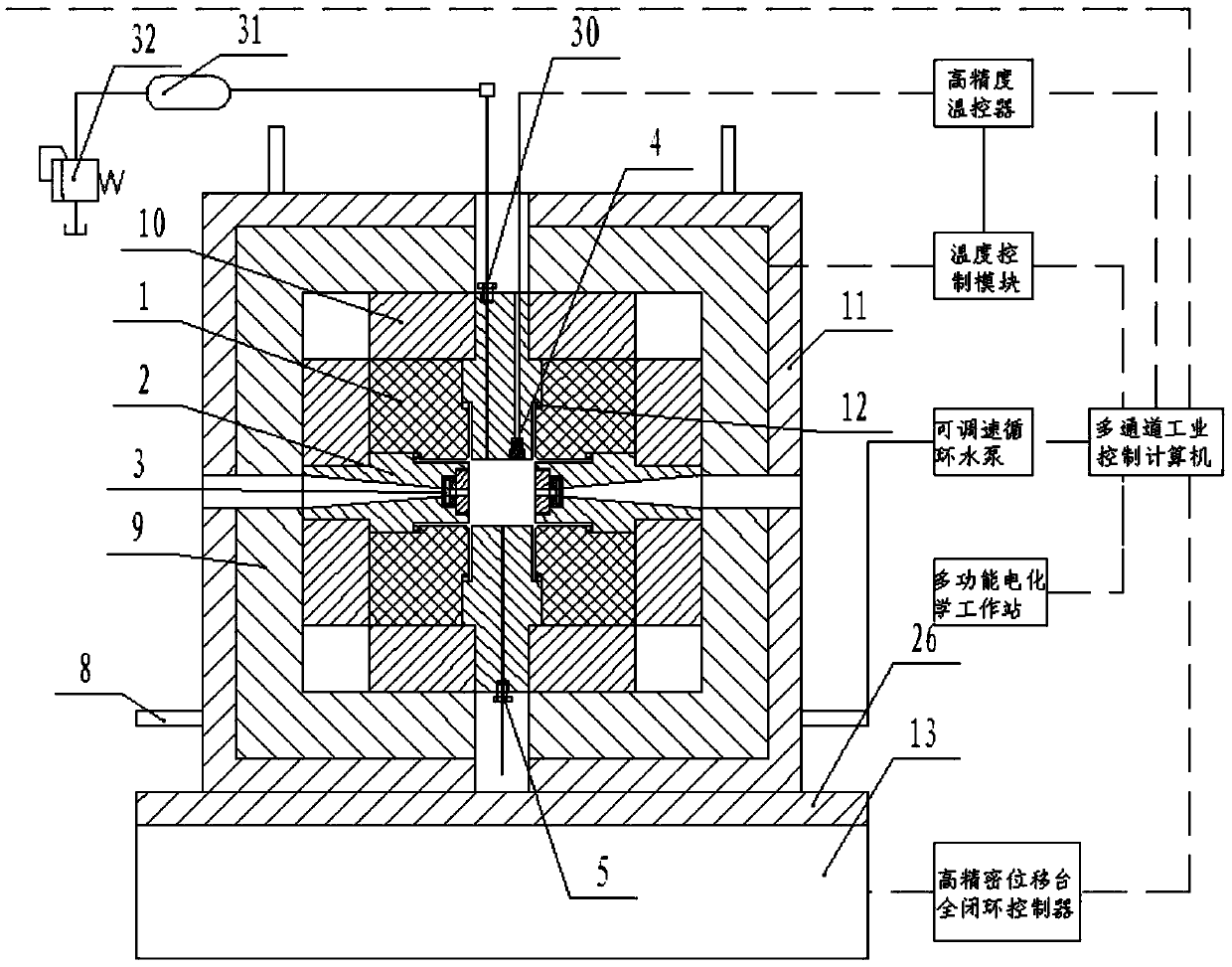

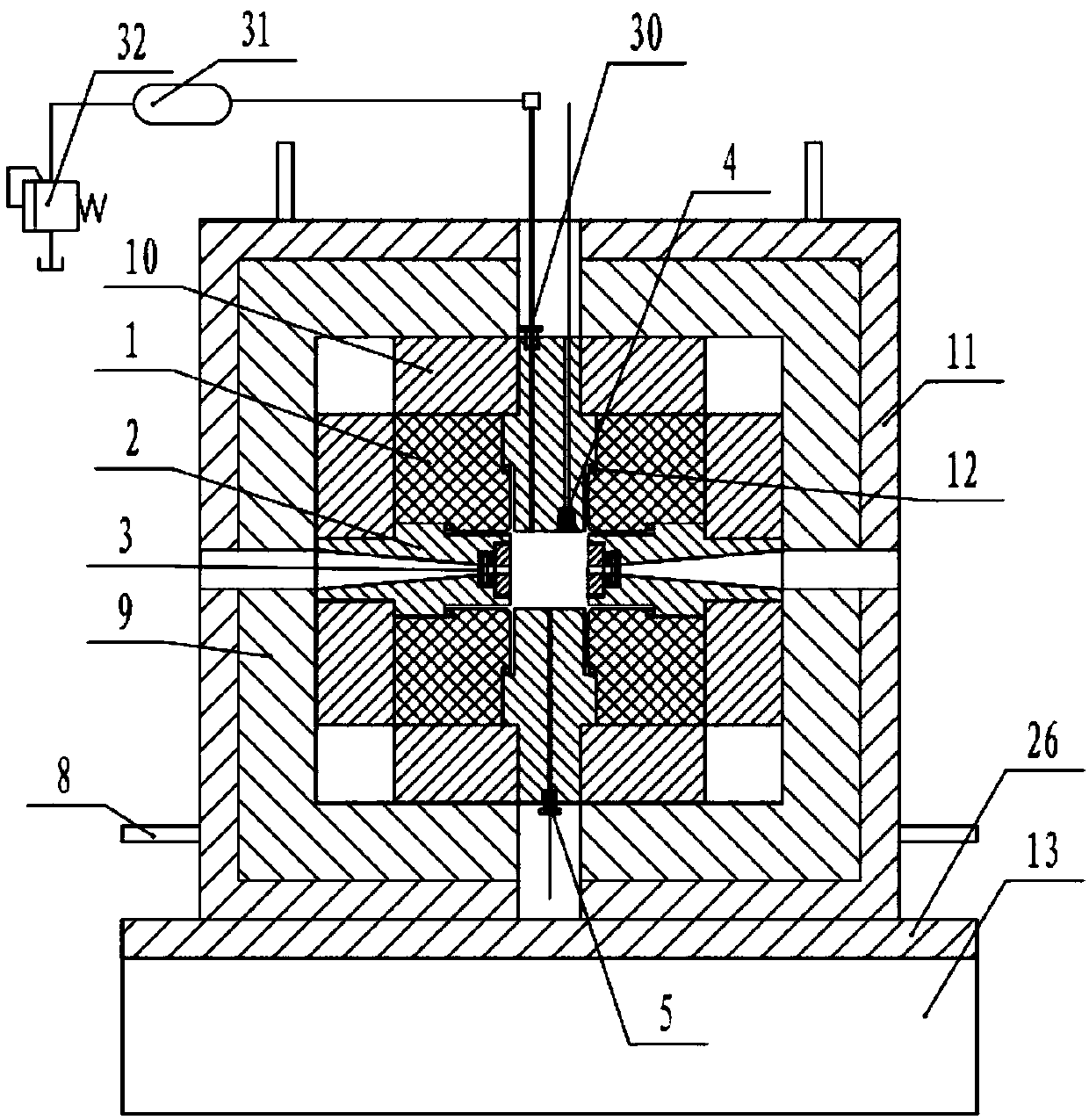

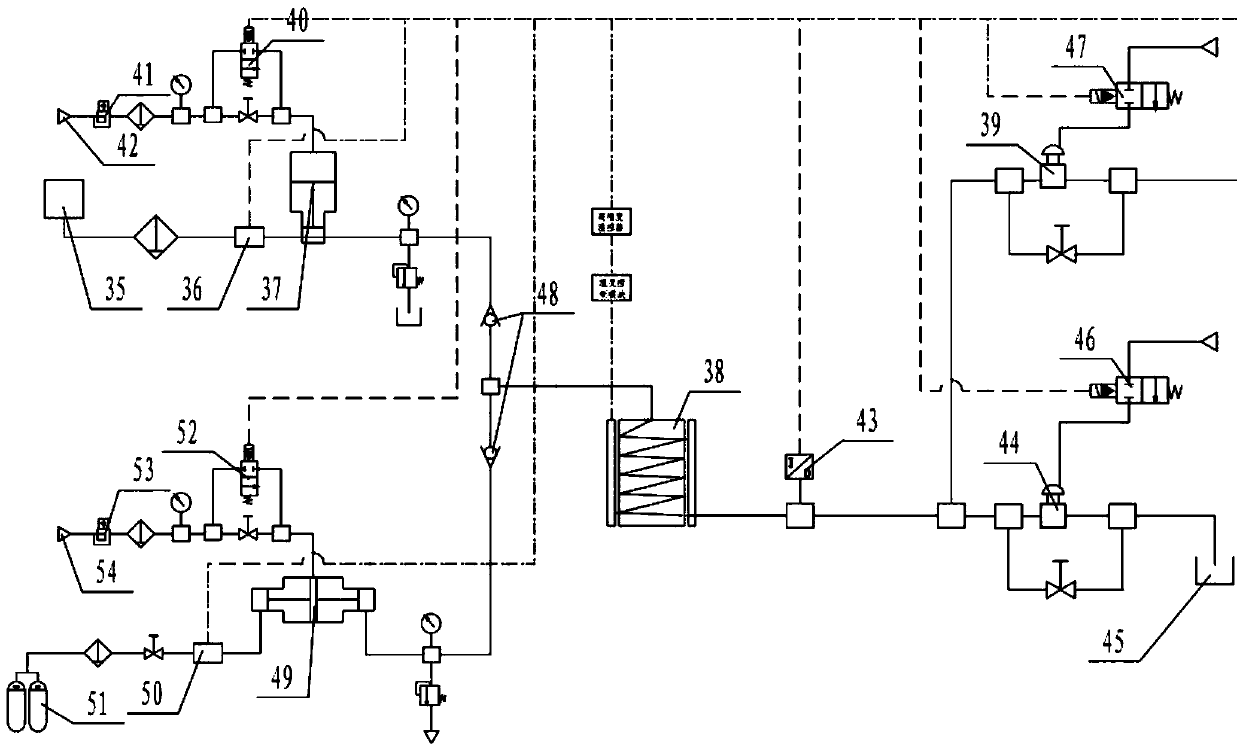

[0058] Embodiment 1: as Figure 1-Figure 12As shown, a large cavity high-temperature and high-pressure gas-liquid two-phase flow experimental device and experimental method, including a kettle body 1 and a kettle plug 2, the kettle body 1 is a hexagonal structure, made of high-temperature nickel-based alloy, directly on a high-temperature nickel-based The alloy is processed on the whole material and formed at one time. The interior is a cavity structure for placing samples. The six sides are respectively connected with six detachable and sealed plugs 2. The plugs are made of high-temperature nickel-based alloys. The appearance of the six plugs is The same size, the three horizontal plugs 2 are equipped with optical windows 3, the remaining three plugs 2 are equipped with three-electrode sensors, pH sensors, Eh sensors or oxygen chemical sensors, and the plugs 2 at the upper end of the kettle body 1 are equipped with high-pressure capillaries. Outlet 30, the kettle plug 2 at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com