Catalyst for producing levoglucosenone, and preparation method thereof

A technology of L-glucosone and catalyst, which is applied in the preparation of sugar derivatives, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of increased preparation cost, high price of ionic liquid catalysts, impossible recycling, etc. Good catalytic effect, promoting activity and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

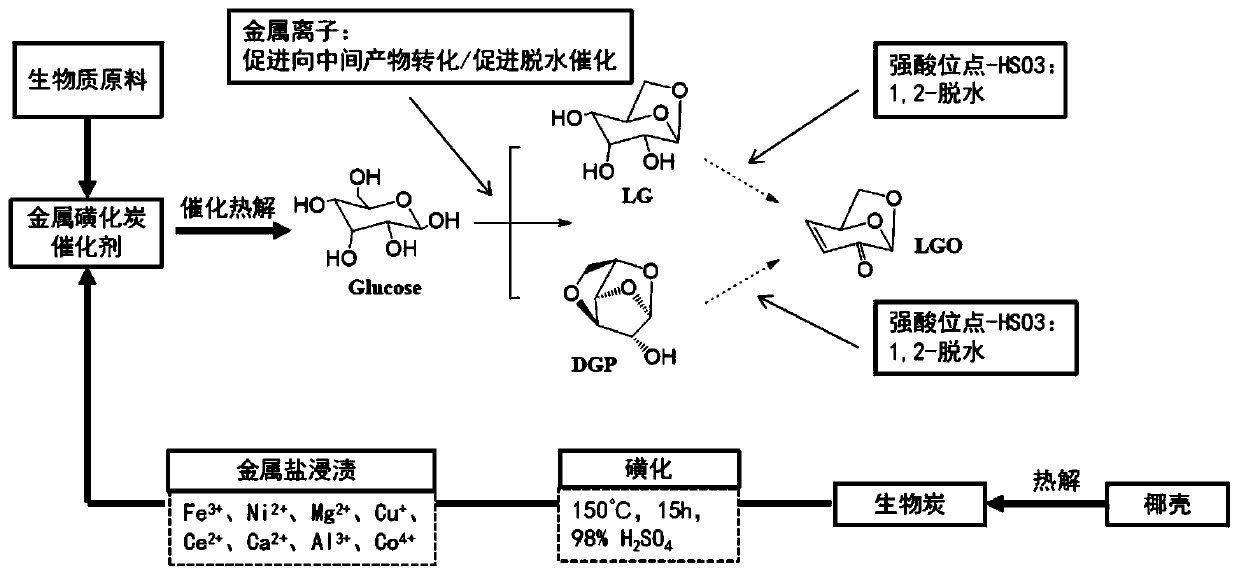

[0037] figure 1 It is a flow chart of the catalyst preparation method for producing levoglucosone according to the embodiment of the present invention. like figure 1 Shown, the present invention provides a kind of catalyst preparation method for producing L-glucosone, comprises the steps:

[0038] S1: The biomass raw material is pulverized and fully mixed with KOH activator at a mass ratio of 4:1 to 1:4, then placed in a reactor, pyrolyzed under the protection of nitrogen, and reacted to obtain biochar, which is pyrolyzed from biomass raw material The temperature is 300°C-600°C, and the pyrolysis time of biomass raw materials is 20min-60min;

[0039]S2: After mixing biochar and concentrated sulfuric acid in S1 at a mass ratio of 1:8 to 1:90, sulfonate in a hydrothermal kettle at 100°C to 180°C for 3h to 15h, and rinse with deionized water to medium after cooling. After curing, use a drying box to dry at 65°C to 120°C for 6h to 12h to obtain sulfonated carbon; the concentrat...

Embodiment 1

[0047] A method for preparing a catalyst for the production of glucosone, comprising the steps of:

[0048] S1: Crush the coconut shell to less than 120 mesh, take 2g sample and mix it with 1g KOH activator, send it into the electric heating reactor, the pyrolysis temperature is 600°C, the pyrolysis time is 30min, and N 2 As shielding gas, N 2 The flow rate is 200ml / min, and the biochar is obtained by cooling. And repeat the experiment to get enough biochar.

[0049] S2: Mix 6g of biochar with concentrated sulfuric acid (98wt%) at a mass ratio of 1:90, sulfonate in a hydrothermal kettle at a constant temperature of 150°C for 12h under a nitrogen atmosphere, cool and filter, and rinse with deionized water to medium properties, placed in a drying oven at 105°C for 6 hours to obtain sulfonated carbon.

[0050] S3: Take 0.5g sulfonated carbon, press Cu 2+ A certain amount of Cu(NO 3 ) 2 ·3H 2 O, configure 10mlCu(NO 3 ) 2 · 3 h 2 O solution.

[0051] S4: Soak sulfonated...

Embodiment 2

[0055] S1: Get 0.5g sulfonated carbon prepared in Example 1, press Ca 2+ A certain amount of Ca(NO 3 ) 2 , configure 10mlCa(NO 3 ) 2 solution.

[0056] S2: Soak sulfonated carbon in the solution for 30min, filter to get Ca 2+ Supported metal sulfonated carbon catalysts.

[0057] S3: Rinse with deionized water, and dry in a drying oven at 105°C for 6 hours.

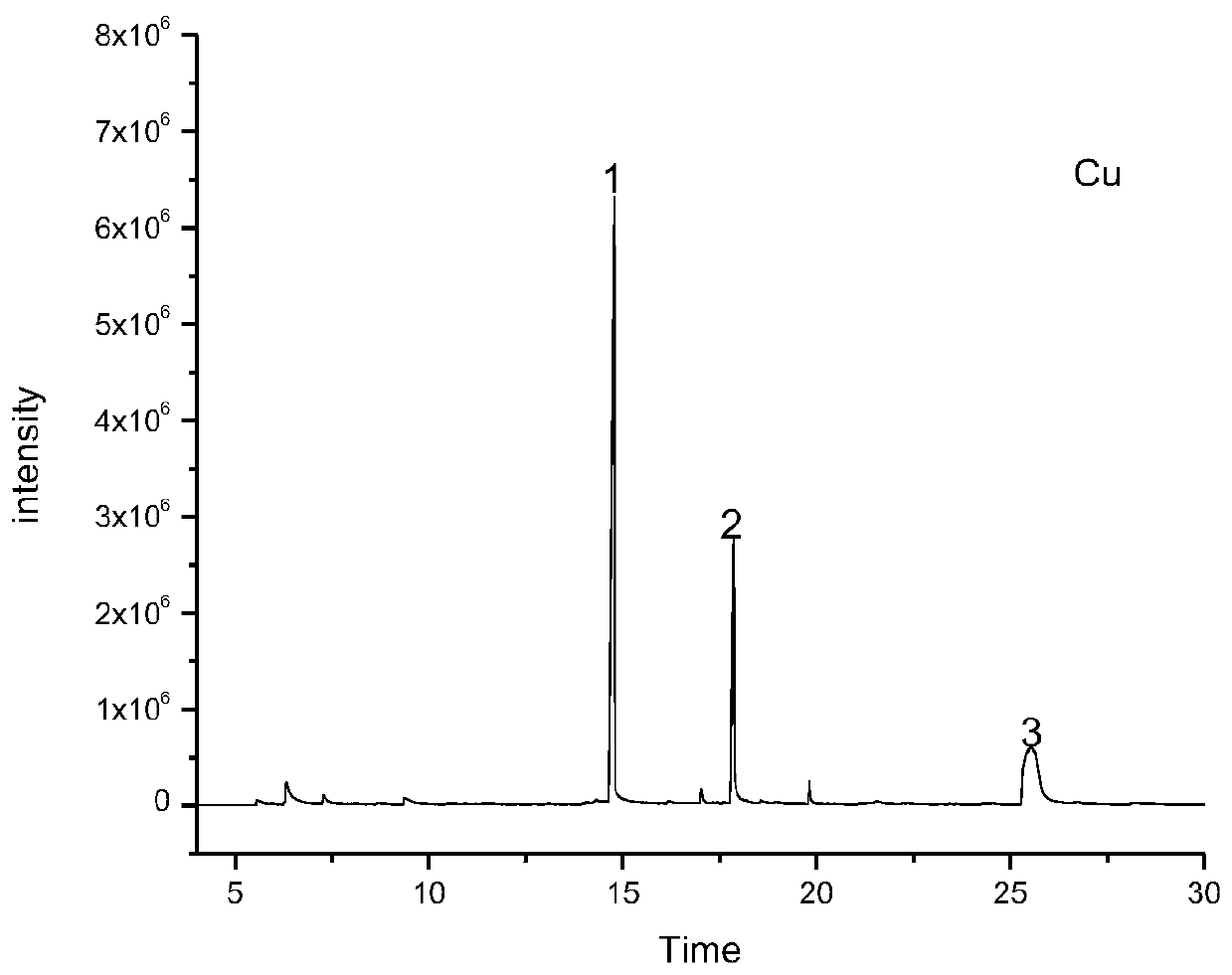

[0058] Further, the method for preparing levoglucosone using a metal sulfonated carbon catalyst comprises the following steps: taking 0.3 mg of the above-mentioned Ca 2+ Loaded metal sulfonated carbon catalyst, using glucopyranose as raw material, mechanically mixing the two, the mass ratio of glucopyranose and catalyst is 1:1, and the mixture is subjected to rapid pyrolysis reaction in PY-GC / MS, 400 ℃ under the atmosphere of helium pyrolysis for 10ms. The content of glucosone was analyzed by gas chromatography-mass spectrometry. Figure 4 As shown, the calculated content of L-glucosone is 53.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com