G-C3N4/MoS2 composite photocatalyst and one-pot preparation method thereof

A technology of g-c3n4 and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problems of cumbersome process, long preparation cycle, and inability to form heterojunction interface, etc. Achieve the effect of large specific surface area and excellent hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] g-C of this example 3 N 4 / MoS 2 The composite photocatalyst was prepared by the following steps:

[0030] (1) Weigh 2.5g of thiourea and 0.0030g of sodium molybdate, put them in an agate mortar, grind them thoroughly for 30 minutes, then weigh 2.5g of urea and continue grinding for 30 minutes, and then place them in a vacuum oven at 60°C for 6 hours to obtain dry mixture;

[0031] (2) Place the dry mixture obtained in step (1) in a semi-closed porcelain boat, and calcinate at 550°C under the protection of nitrogen atmosphere (nitrogen flow rate 10mL / min, heating rate 5°C / min), to obtain g-C 3 N 4 / MoS 2 composite photocatalyst.

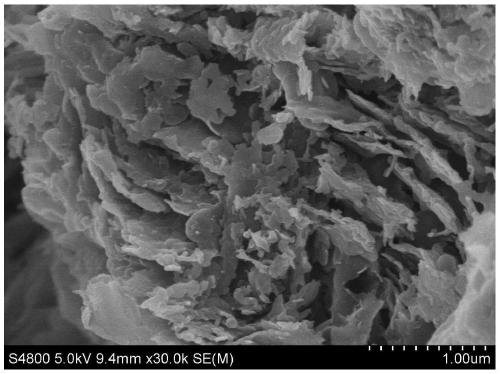

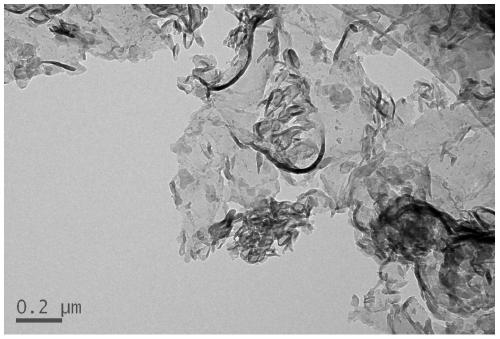

[0032] from figure 1 It can be known that g-C obtained in this embodiment 3 N 4 / MoS 2The morphology of the composite photocatalyst is a porous ultrathin flake interspersed structure, indicating that g-C 3 N 4 with MoS 2 Combine firmly.

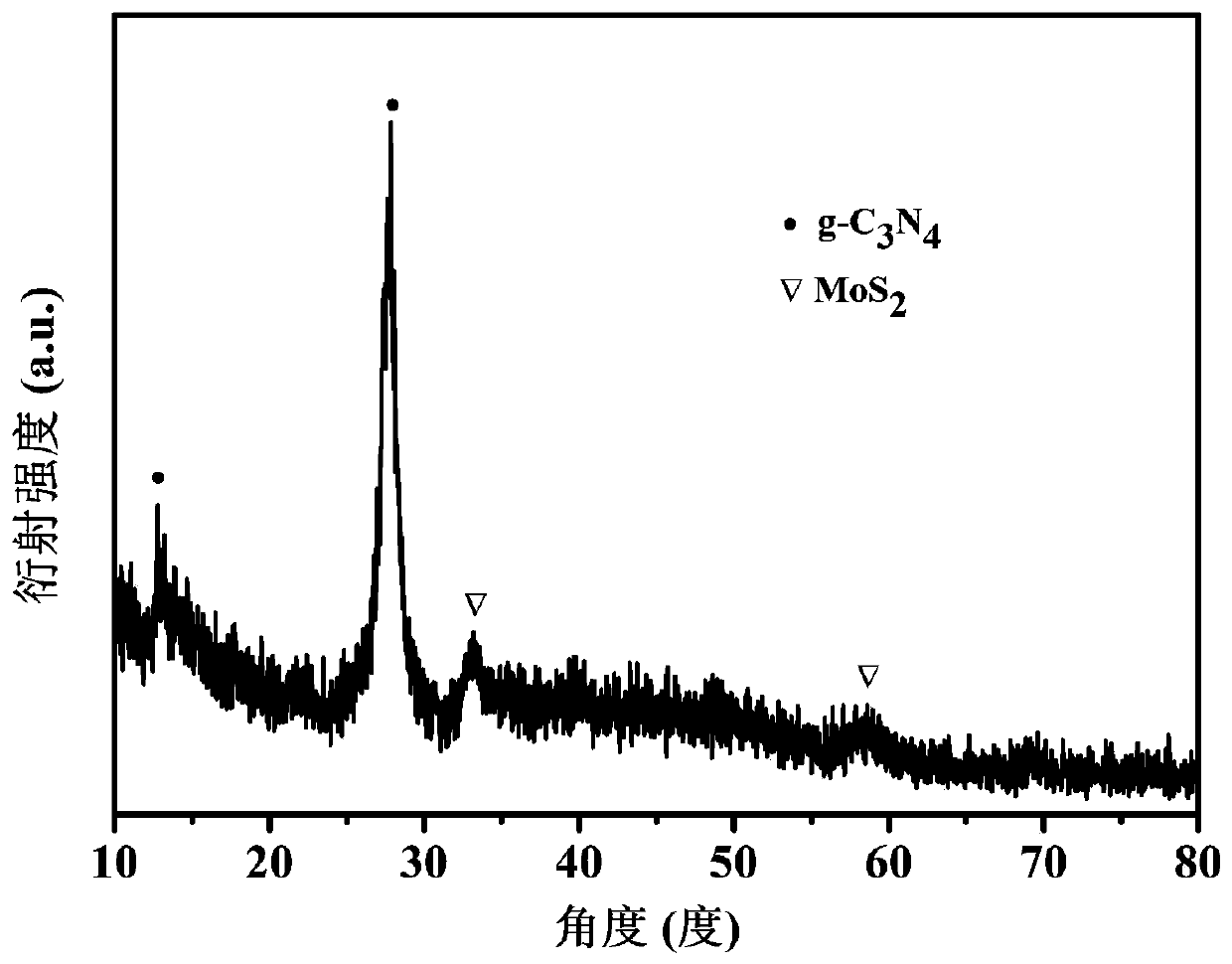

[0033] from figure 2 It can be seen that there is g-C 3 N 4 and MoS 2 The characteristi...

Embodiment 2

[0041] g-C of this example 3 N 4 / MoS 2 The composite photocatalyst was prepared by the following steps:

[0042] (1) Weigh 3 g of thiourea and 0.0050 g of ammonium molybdate, put them in an agate mortar, grind them thoroughly for 20 minutes, then weigh 2 g of urea and continue grinding for 20 minutes, and then place them in a vacuum oven at 80° C. for 10 hours to obtain a dry mixture;

[0043] (2) Place the dry mixture obtained in step (1) in a semi-closed porcelain boat, and calcinate at 500°C under the protection of nitrogen atmosphere (nitrogen flow rate is 5mL / min, heating rate is 2.5°C / min), to obtain g-C 3 N 4 / MoS 2 Composite photocatalyst materials.

Embodiment 3

[0045] g-C of this example 3 N 4 / MoS 2 The composite photocatalyst was prepared by the following steps:

[0046] (1) Weigh 4 g of thiourea and 0.0030 g of ammonium thiomolybdate, put them in an agate mortar, grind them thoroughly for 40 minutes, then weigh 1 g of urea and continue grinding for 40 minutes, and then place them in a vacuum oven at 80°C for 12 hours to obtain dry mixture;

[0047] (2) Place the dry mixture obtained in step (1) in a semi-closed porcelain boat, and calcinate at 520°C under the protection of nitrogen atmosphere (nitrogen flow rate is 8mL / min, heating rate is 4°C / min), to obtain g-C 3 N 4 / MoS 2 Composite photocatalyst materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com