Preparation method of high-temperature alloy plate for aeroplane engine

An aero-engine and superalloy technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of alloy segregation, microstructure instability, durability and fatigue performance reduction, etc. The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

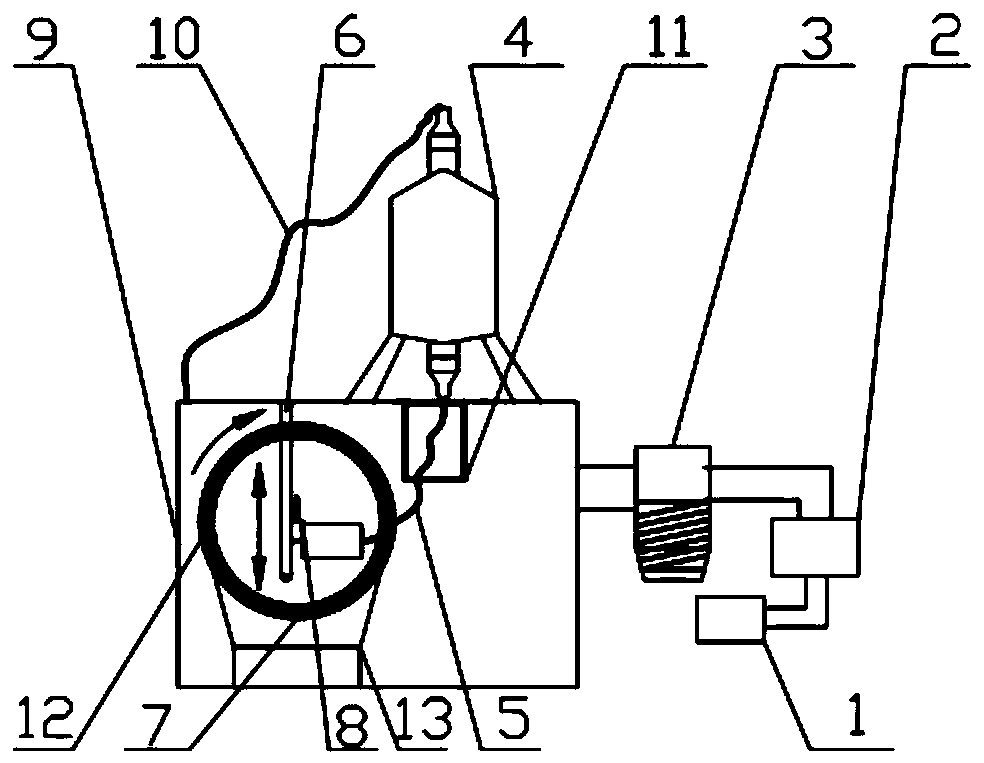

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-temperature alloy disc for an aero-engine of the present invention is specifically implemented according to the following steps:

[0035] Step 1, using vacuum induction, vacuum consumable smelting and plasma rotating electrode method to prepare superalloy powder; the particle size of the obtained superalloy powder is 53 μm, and the oxygen content is less than 60 ppm;

[0036] Step 2, first use electrostatic equipment to electrostatically remove impurities on the superalloy powder, and vacuumize the electrostatic equipment until the vacuum degree is less than 10 -3 Pa, then filled with argon for protection, after electrostatic removal, the content of non-metallic inclusions in the superalloy powder is less than 5 particles / kg;

[0037] Step 3, use self-made powder degassing deposition equipment in a vacuum less than 5×10 -3 Pa, the temperature is 350°C to degas the superalloy powder. After degassing, the oxygen content of the superalloy pow...

Embodiment 2

[0041] A method for preparing a high-temperature alloy disc for an aero-engine of the present invention is specifically implemented according to the following steps:

[0042] Step 1, using vacuum induction, vacuum consumable smelting and plasma rotating electrode method to prepare superalloy powder; the particle size of the prepared superalloy powder is 60 μm, and the oxygen content is less than 60 ppm;

[0043] Step 2, first use electrostatic equipment to electrostatically remove impurities on the superalloy powder, and vacuumize the electrostatic equipment until the vacuum degree is less than 10 -3 Pa, then filled with argon for protection, after electrostatic removal, the content of non-metallic inclusions in the superalloy powder is less than 5 particles / kg;

[0044] Step 3, use self-made powder degassing deposition equipment in a vacuum less than 5×10 -3 Pa, the temperature is 400°C to degas the superalloy powder. After degassing, the oxygen content of the superalloy powde...

Embodiment 3

[0048] A method for preparing a high-temperature alloy disc for an aero-engine of the present invention is specifically implemented according to the following steps:

[0049] Step 1, using vacuum induction, vacuum consumable smelting and plasma rotating electrode method to prepare superalloy powder; the particle size of the prepared superalloy powder is 102 μm, and the oxygen content is less than 60 ppm;

[0050] Step 2, first use electrostatic equipment to electrostatically remove impurities on the superalloy powder, and vacuumize the electrostatic equipment until the vacuum degree is less than 10 -3 Pa, then filled with argon for protection, after electrostatic removal, the content of non-metallic inclusions in the superalloy powder is less than 5 particles / kg;

[0051] Step 3, use self-made powder degassing deposition equipment in a vacuum less than 5×10 -3 Pa, the temperature is 450°C to degas the superalloy powder. After degassing, the oxygen content of the superalloy po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com