Flow-equalization-type fire sheet

A fire piece and flow-type technology, applied to gas fuel burners, combustion methods, combustion types, etc., can solve problems affecting the stability of air-fuel ratio, complex head structure, and increased carbon monoxide emissions, so as to shorten the generation time, Easy to popularize and use, reduce the effect of carbon monoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

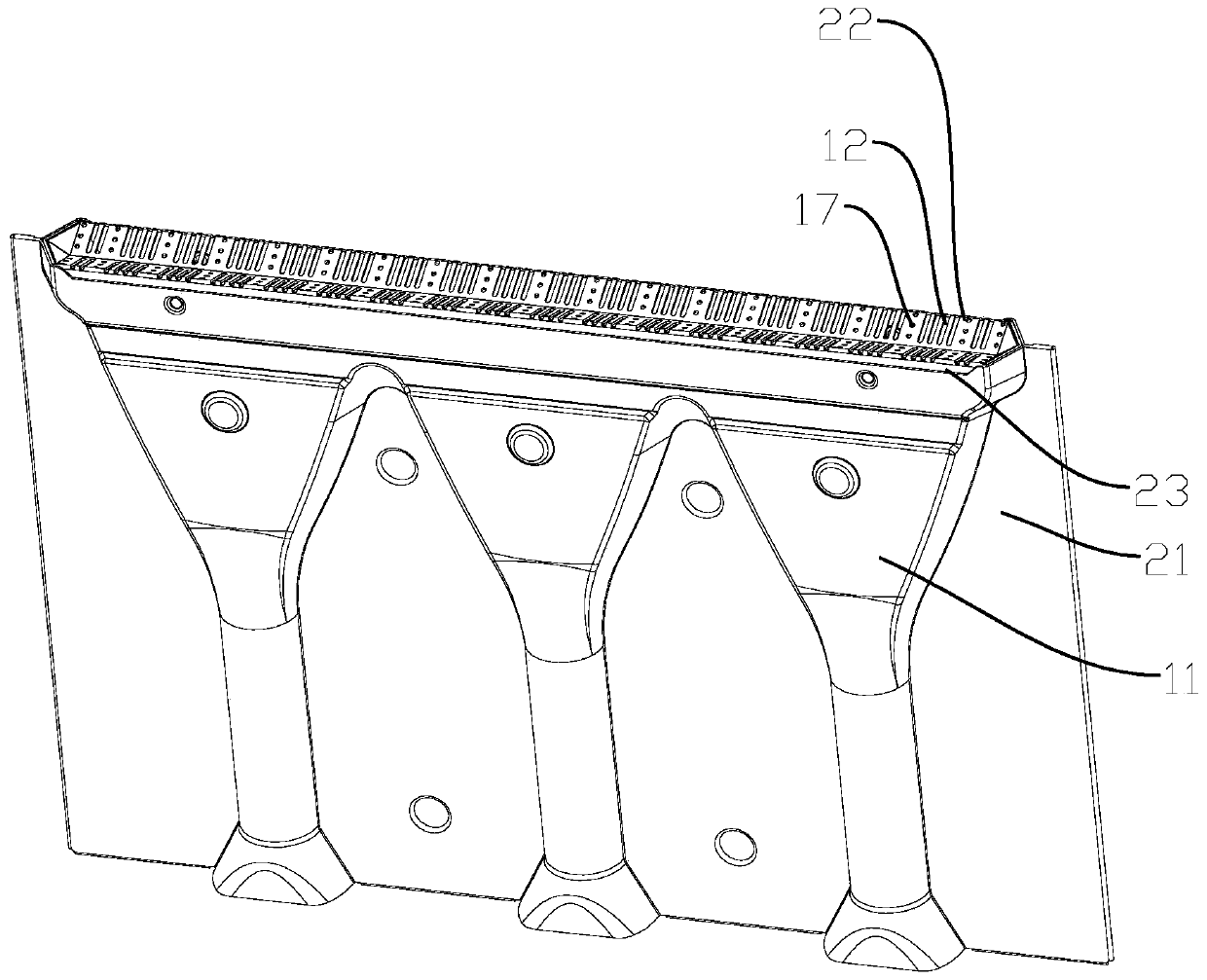

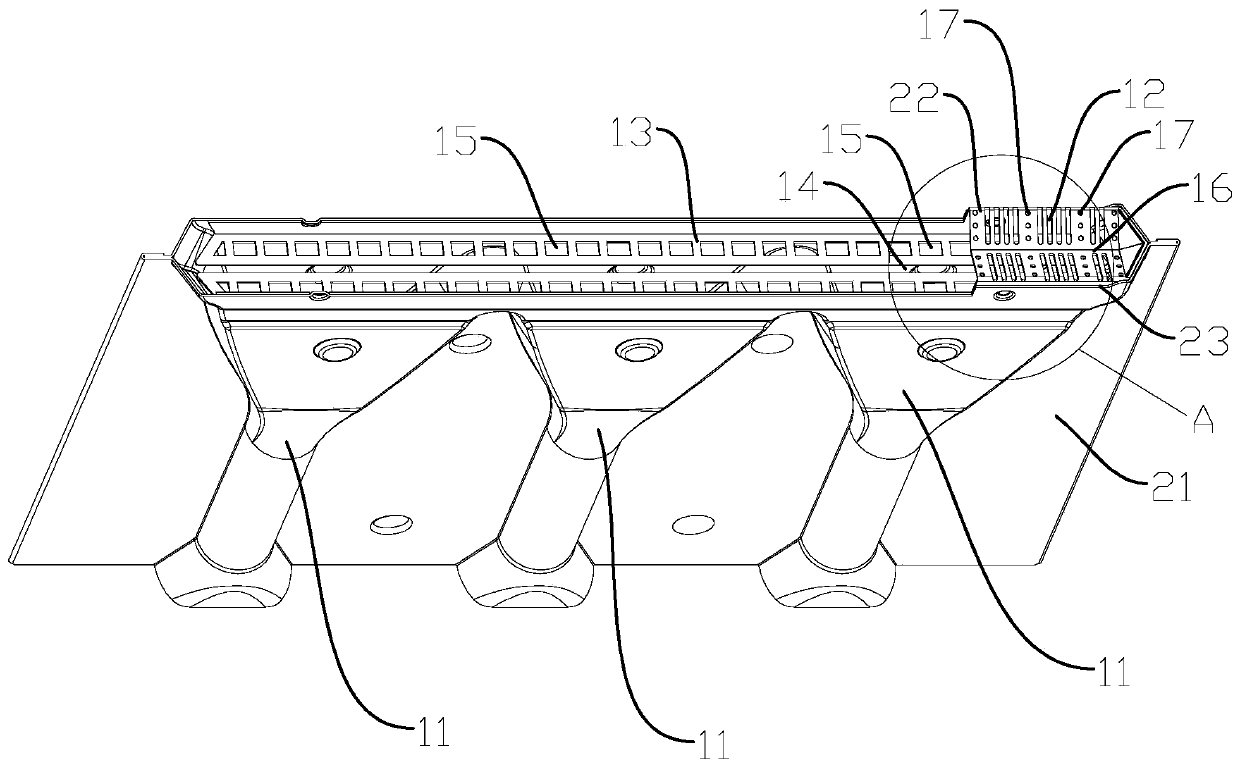

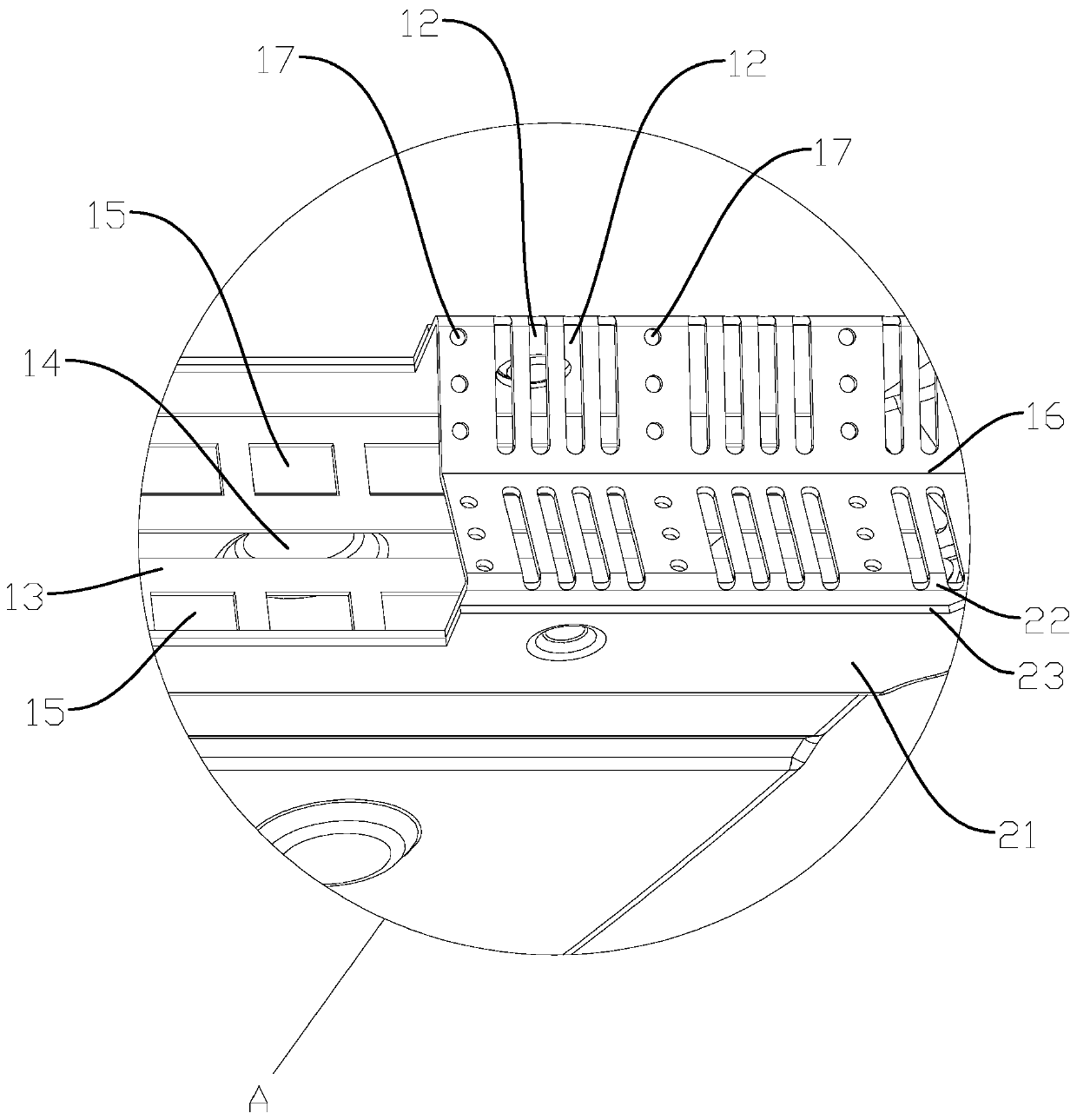

[0024] refer to Figure 1 to Figure 4 , a flow equalizing fire piece, comprising a fire piece main body, a gas passage 11 is provided inside the fire piece main body, a fire hole 12 is arranged on the top plate of the fire piece main body, and a horizontal fire hole 12 below the fire hole 12 is arranged in the gas passage 11 A flow equalizer 13, the middle part of the flow equalizer 13 has a strip-shaped first spoiler hole 14 parallel to the front-to-back direction, and the left and right parts of the flow balance plate 13 are respectively provided with a plurality of second spoiler holes 15, these The second spoiler holes 15 are distributed along the front-to-rear direction. In the present invention, due to the addition of a flow equalizer plate 13 in the gas passage 11, it can play the role of turbulence, flow equalization and flow limitation to the airflow in the gas passage 11, and the flow equalization effect can make the flame of the fire piece burn It is more uniform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com