Multilayer composite neutron target and preparation method thereof

A multi-layer composite and neutron technology, which is applied in the direction of nuclear reaction targets, accelerators, DC voltage accelerators, etc., to reduce the replacement of deuterium-tritium atoms, improve service life and neutron yield, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

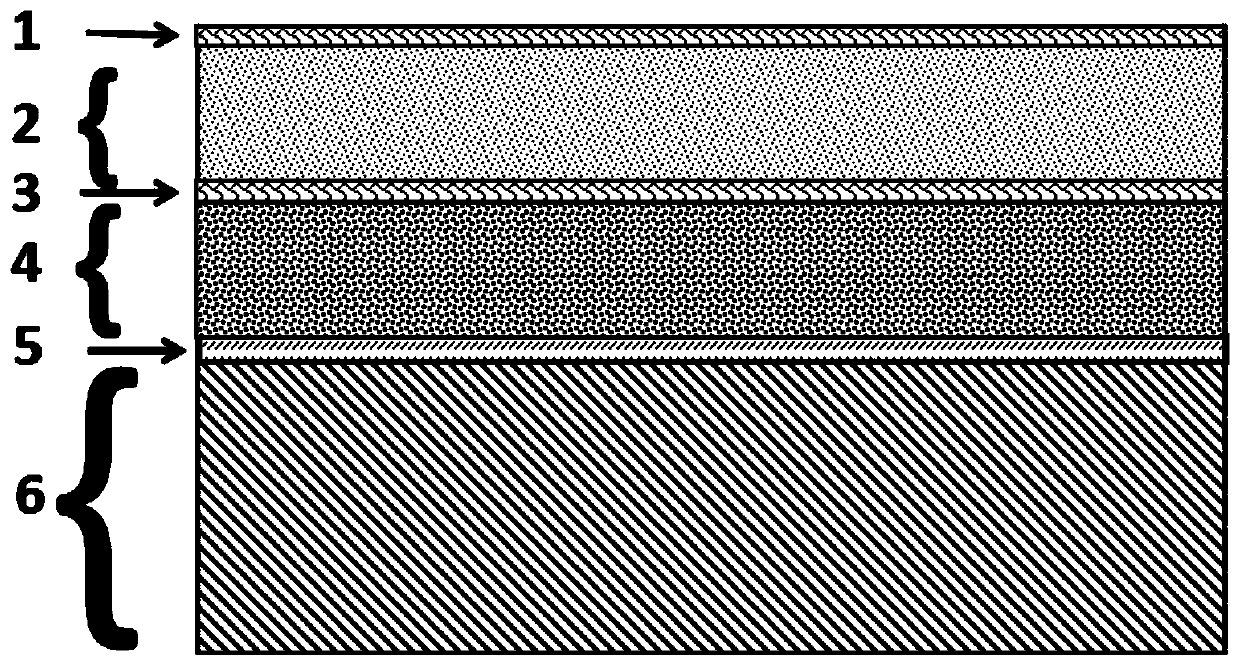

[0025] A multi-layer composite neutron target, comprising a surface tritium permeable layer 1, a tritium storage layer 2, an internal tritium permeable layer 3, a hydrogen isotope storage layer 4, a buffer guide layer 5 and a base layer 6 sequentially composited from top to bottom .

[0026] The inner tritium permeable layer is located between the hydrogen isotope storage layer and the tritium storage layer, and the surface tritium permeable layer is located on the surface of the tritium storage layer. The material of the base layer is chrome-zirconium copper, the buffer guide layer is metal palladium, the material of the internal tritium-resistant penetration layer is erbium oxide, the material of the surface tritium-resistant penetration layer is single-layer graphene, and the materials of the hydrogen isotope storage layer and the tritium storage layer Both are titanium-magnesium alloys, the thickness of the titanium-magnesium alloy film is 3 μm, and the atomic ratio of tit...

Embodiment 2

[0034] A multi-layer composite neutron target, including a surface tritium permeable layer 1, a tritium storage layer 2, an internal tritium permeable layer 3 and a base layer 6, which are sequentially composited from top to bottom. This embodiment does not include a hydrogen isotope storage layer and a tritium storage layer. Buffer boot layer. For the sake of concise description, the accompanying drawings will not be repeated.

[0035] The inner tritium permeable layer is located between the base layer and the tritium storage layer, and the surface tritium permeable layer is located on the surface of the tritium storage layer. The material of the base layer is chromium-zirconium copper, the material of the internal tritium-resistant permeable layer and the surface tritium-resistant permeable layer is single-layer graphene, the material of the tritium storage layer is titanium-magnesium alloy, the thickness of the titanium-magnesium alloy film is 3 μm, and the titanium-magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com