A kind of particle that can reduce the temperature of cigarette smoke and its preparation method and application

A technology for cigarette smoke and particles, which is applied in the field of particles for reducing the temperature of mainstream smoke of cigarettes and their preparation, can solve problems such as sticking and collapse, reducing cooling surface area, blocking pores, etc., and achieves the effect of surface densification and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

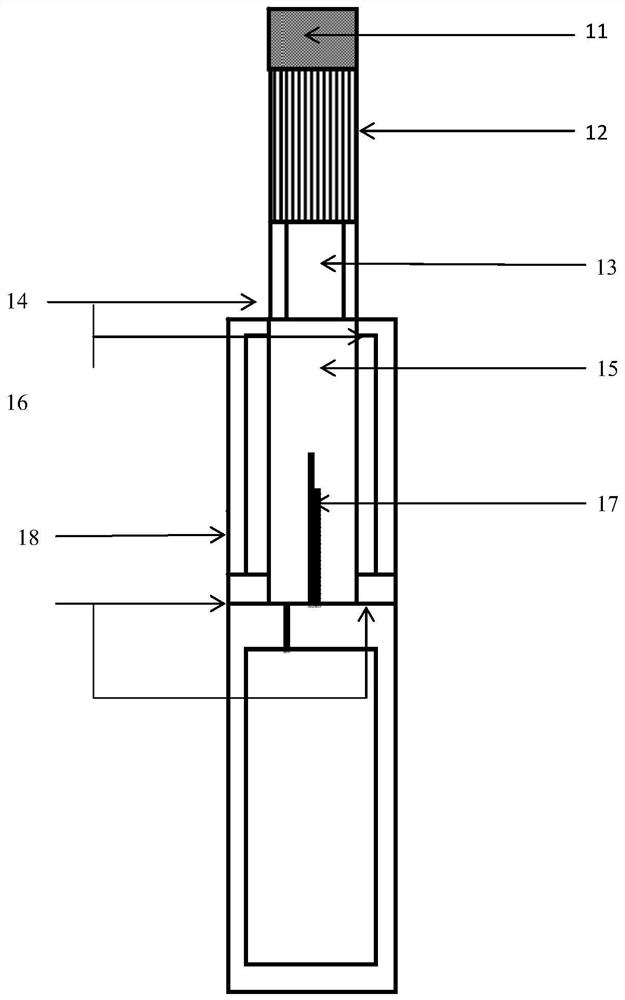

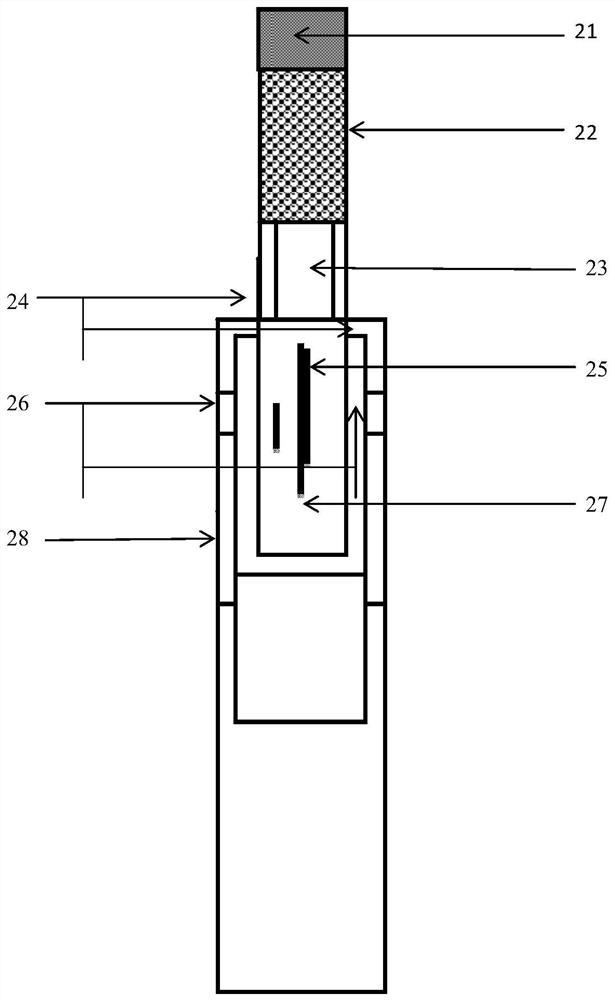

Image

Examples

Embodiment 1

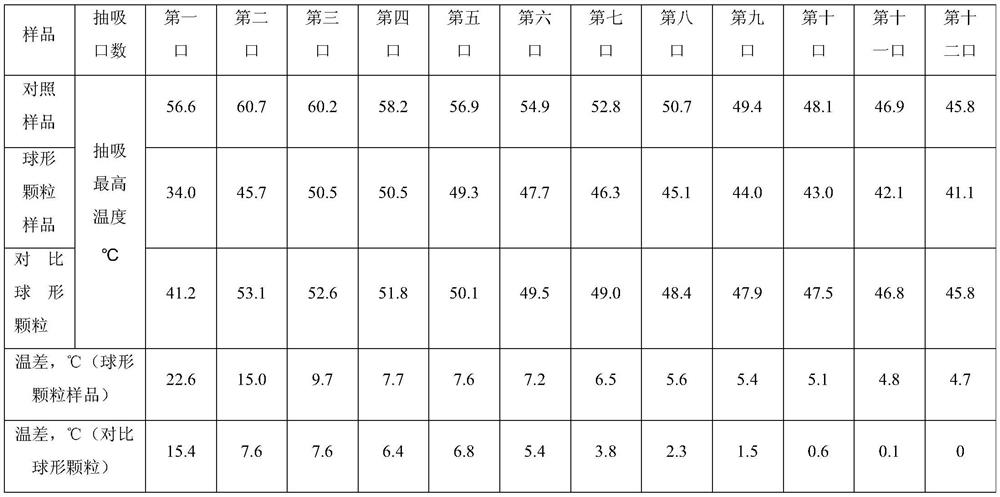

[0086]The commercial cellulose diacetate was wet-ground into powder with an average particle size of 48 microns. Weigh 1 kg of the above ground powder sample, add 1.18 kg of 7.8% hydroxypropyl methylcellulose (HPMC) aqueous solution, and fully stir and mix on a laboratory wet mixer to obtain a wet material. The soft wet material prepared above was subjected to wet extrusion and granulation on an E-50 wet extruder (distribution plate aperture 1.0 mm) to obtain cylindrical bars. The feed speed of the extruder was 23 rpm and the extrusion speed was 26 rpm. The cylindrical bar was spheronized on an S-250 spheronizer to obtain spherical wet granules. The spheronization conditions are as follows: the spheronizer first works at 600rpm for 1.5 minutes, and then works at 500rpm for 3 minutes. The above spherical wet granules were dried at 105-120°C for 5-6 hours to remove moisture to obtain dry active granules (and serve as comparative spherical granules for the flue gas temperature ...

Embodiment 2

[0092] Weigh 1 kilogram of industrial microcrystalline cellulose (produced by Anhui Shanhe Company, the average particle size of the powder is 45 microns), add 1.22 kilograms of 9.1% pregelatinized starch aqueous solution, fully stir and mix on a laboratory wet mixer to obtain a wet material . The soft wet material prepared above was subjected to wet extrusion and granulation on an E-50 wet extruder (distribution plate aperture 1.0 mm) to obtain cylindrical bars. The feed speed of the extruder was 24 rpm and the extrusion speed was 27 rpm. The cylindrical bar was spheronized on an S-250 spheronizer to obtain spherical wet granules. The spheronization conditions are as follows: the spheronizer first works at 650rpm for 2 minutes, and then works at 450rpm for 3 minutes. The spherical wet granules prepared above are dried at a temperature of 105-120° C. for 5-6 hours to remove moisture to obtain dry active granules. The dried inner layer rigid solid spheres were sprayed at the...

Embodiment 3

[0098] Weigh 1 kilogram of industrial microcrystalline cellulose powder sample (produced by Anhui Shanhe Company, the average particle size of the powder is 45 microns), add 1.22 kilograms of 9.1% pregelatinized starch aqueous solution, and fully stir and mix on a laboratory wet mixer. Wet material. The soft wet material prepared above was subjected to wet extrusion and granulation on an E-50 wet extruder (distribution plate aperture 1.0 mm) to obtain cylindrical bars. The feed speed of the extruder was 24 rpm and the extrusion speed was 27 rpm. The cylindrical bar was spheronized on an S-250 spheronizer to obtain spherical wet granules. The spheronization conditions are as follows: the spheronizer first works at 650rpm for 2 minutes, and then works at 450rpm for 3 minutes. The spherical wet granules prepared above are dried at a temperature of 105-120° C. for 5-6 hours to remove moisture to obtain dry active granules. The dried active granules are film-coated with a bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com