La2O3 cluster modified Ni/SiO2 nano composite catalyst and preparation method thereof

A nanocomposite and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor stability, achieve easy operation, and reduce production costs , Excellent catalytic stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

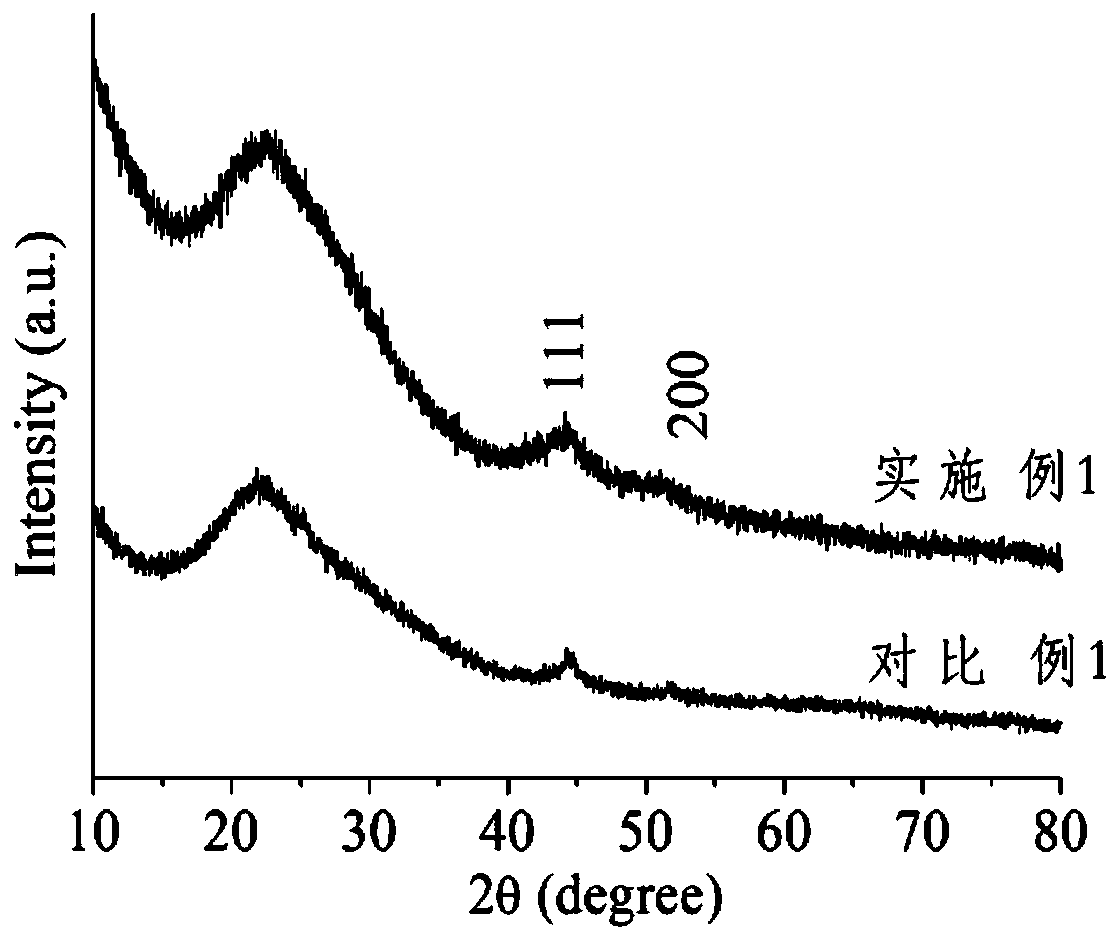

Embodiment 1

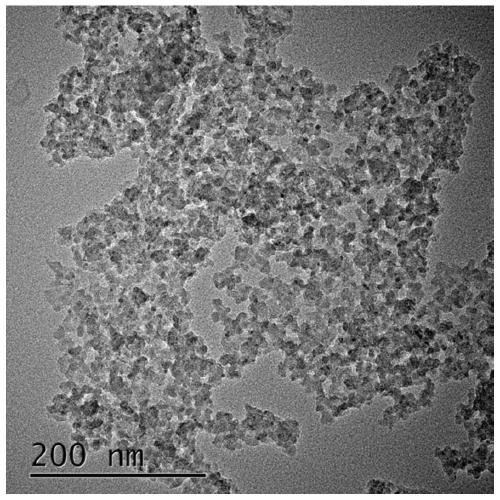

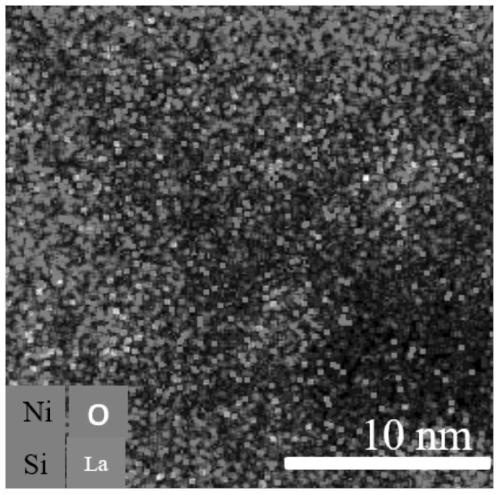

[0042] La in this example 2 o 3 Cluster Modified Ni / SiO 2 The nanocomposite catalyst consists of mesoporous silica with a mesoporous diameter of 9.6nm, nickel nanocrystals with an average particle diameter of 4.5nm and lanthanum oxide (La 2 o 3 ) composition; nickel nanocrystals are supported on mesoporous silica, and the surface of nickel nanocrystals is attached with lanthanum oxide, wherein, the molar number of lanthanum in lanthanum oxide is La 2 o 3 Cluster Modified Ni / SiO 2 2% by mole of nanocomposite catalyst.

[0043] Prepare the La of the present embodiment according to the following method 2 o 3 Cluster Modified Ni / SiO 2 Nanocomposite catalyst, it specifically comprises the following steps:

[0044] 1) Weigh 26.4306g Na 2 SiO 3 9H 2 O in a beaker, then, add 87.2154g deionized water and keep stirring until Na 2 SiO 3 9H 2 O is completely dissolved to give 10% Na by mass fraction 2 SiO 3 solution, subsequently, under continuous magnetic stirring condit...

Embodiment 2

[0062] La in this example 2 o 3 Cluster Modified Ni / SiO 2 The nanocomposite catalyst consists of mesoporous silica with a mesoporous diameter of 7.3nm, nickel nanocrystals with an average particle diameter of 4.2nm and lanthanum oxide (La 2 o 3 ) composition; nickel nanocrystals are supported on mesoporous silica, and the surface of nickel nanocrystals is attached with lanthanum oxide, wherein, the molar number of lanthanum in lanthanum oxide is La 2 o 3 Cluster Modified Ni / SiO 2 0.5% by mole of nanocomposite catalyst.

[0063] Prepare the La of the present embodiment according to the following method 2 o 3 Cluster Modified Ni / SiO 2 Nanocomposite catalyst, it specifically comprises the following steps:

[0064] 1) Weigh 26.8569g Na 2 SiO 3 9H 2 O in a beaker, then, add 88.6221g deionized water and keep stirring until Na 2 SiO 3 9H 2 O is completely dissolved to give 10% Na by mass fraction 2 SiO 3 solution, subsequently, under continuous magnetic stirring cond...

Embodiment 3

[0071] La in this example 2 o 3 Cluster Modified Ni / SiO 2 The nanocomposite catalyst consists of mesoporous silica with a mesoporous diameter of 10.3nm, nickel nanocrystals with an average particle diameter of 4.7nm and lanthanum oxide (La 2 o 3 ) composition; nickel nanocrystals are supported on mesoporous silica, and the surface of nickel nanocrystals is attached with lanthanum oxide, wherein, the molar number of lanthanum in lanthanum oxide is La 2 o 3 Cluster Modified Ni / SiO 2 1% by mole of nanocomposite catalyst.

[0072] Prepare the La of the present embodiment according to the following method 2 o 3 Cluster Modified Ni / SiO 2 Nanocomposite catalyst, it specifically comprises the following steps:

[0073] 1) Weigh 26.7148Na 2 SiO 3 9H 2 O in a beaker, then, add 88.1532g deionized water and keep stirring until Na 2 SiO 3 9H 2 O is completely dissolved to give 10% Na by mass fraction 2 SiO 3 solution, subsequently, under continuous magnetic stirring conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com