Asymmetric composite anode of microtuble-type solid oxide fuel cell and preparation method of asymmetric composite anode

A solid oxide and fuel cell technology, applied to fuel cell parts, battery electrodes, circuits, etc., can solve problems such as easy delamination, long process route, and weak interlayer bonding, and achieve anti-carbon deposition And the effect of good sulfur resistance, small gas diffusion resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

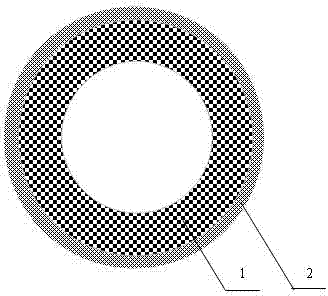

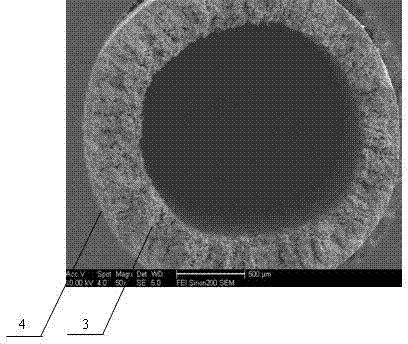

[0031] Example 1 Preparation of Cu-CeO 2 -YSZ / Ni-YSZ asymmetric composite anode microtubes

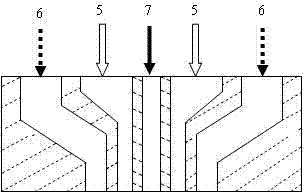

[0032] The steps are as follows: preparation of ceramic-polymer slurry; preparation of electrolyte / Ni-based anode bilayer asymmetric microtubes with hierarchical porous structure; Cu-CeO 2 Based anode catalyst deposition and reduction, in which:

[0033] (1) Preparation of ceramic-polymer slurry

[0034] The organic polymer in this example is polyethersulfone (PESf); the solvent is N-methylpyrrolidone (NMP); the additive is polyvinylpyrrolidone (PVP); the ceramic electrolyte is 0.05-2 μm 8% yttrium-stabilized zirconia ( YSZ for short, commercially available, produced by Yixing Zhongtai Ceramic New Material Co., Ltd.); NiO powder is commercially available, with a particle size of 0.1-2 μm; the weight percentage composition of each component when preparing the polymer slurry is: A The slurry is, YSZ: PESf: NMP: PVP = 57%: 3%: 30%: 10%; the B slurry is, YSZ: NiO: PESf: NMP: PVP =...

Embodiment 2

[0040] Example 2 Preparation of Cu-CeO 2 -SDC / Ni-SDC asymmetric composite anode microtubes

[0041] Concrete steps are with embodiment 1. The materials and operating parameters used in this example are as follows:

[0042] (1) The organic polymer is polysulfone (PSf); the solvent is dimethyl sulfoxide (DMSO); the additive is sodium polymethacrylate; the ceramic electrolyte is 0.4~2 μm samarium-doped cerium oxide (SDC); NiO powder It is a commercially available product with a particle size of 0.1-2 μm; when preparing polymer slurry, the weight ratio of each component is: A slurry is, SDC: PSf: DMO: sodium polymethacrylate = 66: 10: 23.5: 0.5; B slurry is, SDC:NiO:PSf:DMO:sodium polymethacrylate=32:40:5:22:1.

[0043] (2) During the spinning process, the internal coagulation liquid is a mixture of solvent DMSO and non-solvent ethanol water; the weight percentage of the solvent is 95%; the sintering temperature of the double-layer microtube is 1550 ° C, and the sintering...

Embodiment 3

[0046] Example 3 Preparation of Cu-CeO 2 -YSZ / Ni-GDC asymmetric composite anode microtubes

[0047] Concrete steps are with embodiment 1. The materials and operating parameters used in this example are as follows:

[0048] (1) The organic polymer is polyethersulfone (PESf); the solvent is N,N-dimethylacetamide (DMAc); the additives are glycerol and PVP; the ceramic electrolyte is commercially available 8% YSZ and particle size of 0.05~2 μm Gadolinium-doped cerium oxide (GDC) is 0.1~2μm; NiO powder is a commercially available product with a particle size of 0.1~2μm; when preparing polymer slurry, the weight ratio of each component is: A slurry is, YSZ : PESf: DMAc: glycerol = 70: 3: 25: 2; B slurry is, GDC: NiO: PESf: DMAc: PVP = 37: 38: 4: 20: 1.

[0049] (2) During the spinning process, the internal condensate is a mixture of solvent N,N-dimethylacetamide and non-solvent propanol; the weight percentage of the solvent is 95%; the sintering temperature of the double-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com