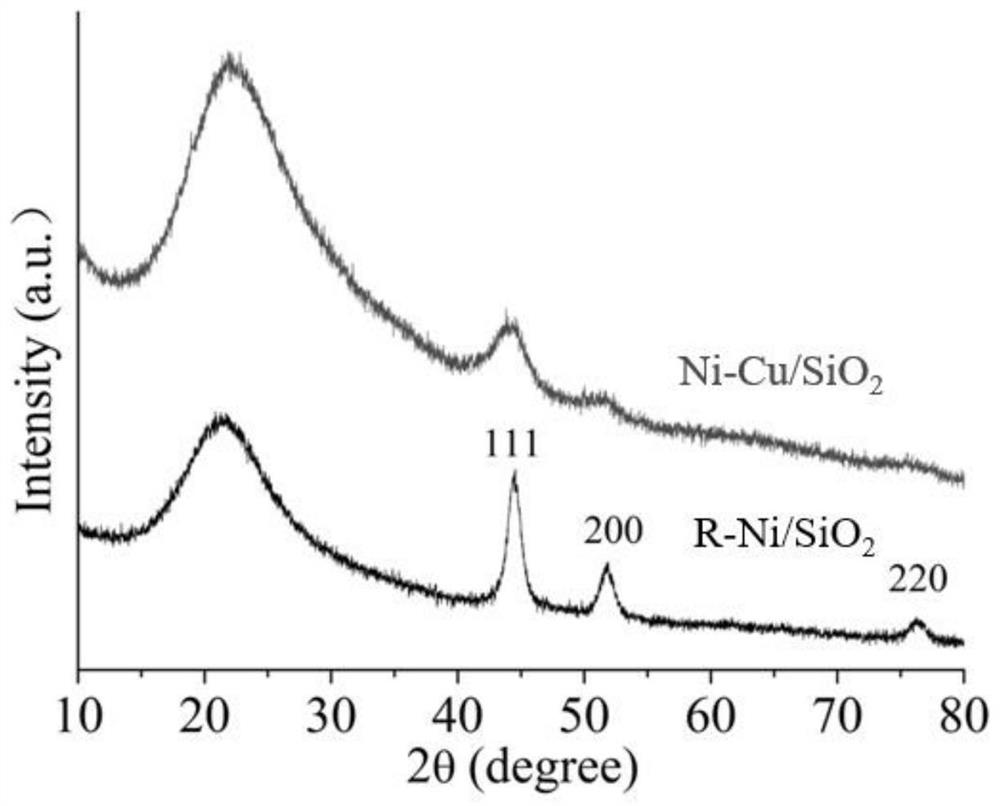

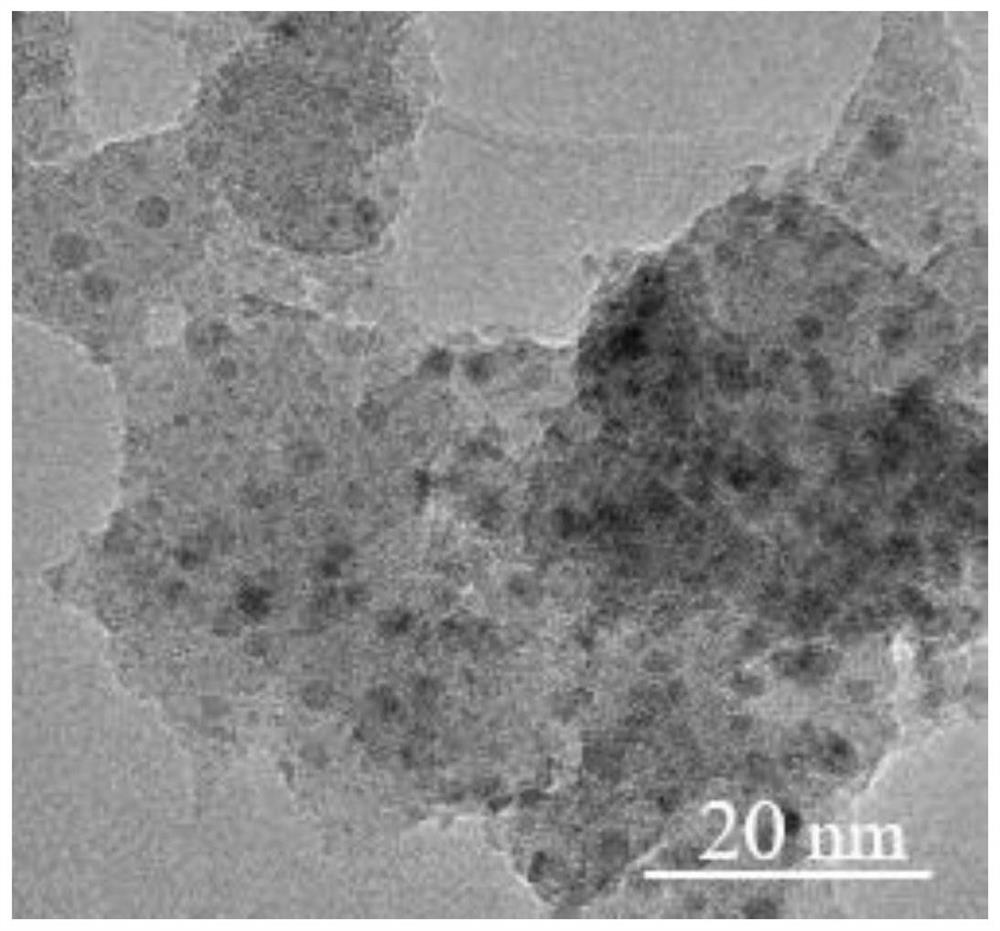

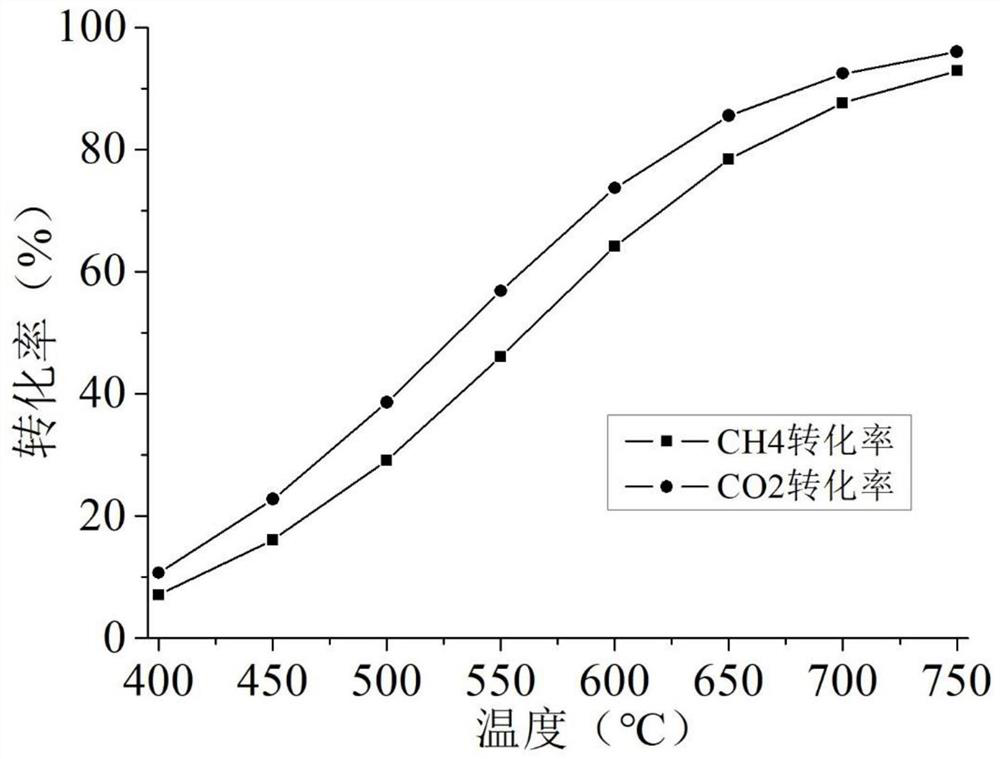

A copper-doped ni/sio 2 Nanocomposite catalyst and preparation method thereof

A nano-composite and catalyst technology, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve complex metal components, complicated preparation process and large dosage and other problems, to achieve the effect of simple process, wide range of sources, and excellent anti-carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A copper-doped Ni / SiO 2 Nano composite catalyst, its preparation method comprises the steps:

[0041] 1) Weigh 25.578g Na 2 SiO 3 9H 2 O was placed in a beaker, and 84.402g of distilled water was added for ultrasonic dissolution to obtain Na 2 SiO 3 solution; dilute analytically pure concentrated nitric acid and distilled water at a volume ratio of 1:4 and add dropwise to the obtained Na 2 SiO 3 In the solution, magnetic stirring is carried out while adding dropwise, until pH=6, and mixed solution I is obtained;

[0042] 2) Weigh 2.617g Ni(NO 3 ) 2 ·6H 2 O was put into a beaker, and 13.833g of distilled water was added for ultrasonic dissolution to obtain a nickel salt solution; 0.2416g Cu(NO 3 ) 2 ·3H 2 O is put into a beaker, and 10 g of distilled water is added for ultrasonic dissolution to obtain a copper salt solution; then the obtained nickel salt solution and copper salt solution solution are added dropwise to the mixed solution I, and magnetic stirring...

Embodiment 2

[0059] A copper-doped Ni / SiO 2 Nano composite catalyst, its preparation method comprises the steps:

[0060] 1) Weigh 25.578g Na 2 SiO 3 9H 2 O was placed in a beaker, and 84.402g of distilled water was added for ultrasonic dissolution to obtain Na 2 SiO 3 solution; dilute analytically pure concentrated nitric acid and distilled water at a volume ratio of 1:4 and add dropwise to the obtained Na 2 SiO 3 In the solution, magnetic stirring is carried out while adding dropwise, until pH=6, and mixed solution I is obtained;

[0061] 2) Weigh 2.7825g Ni(NO 3 ) 2 ·6H 2 O was put into a beaker, and 14.5825g of distilled water was added for ultrasonic dissolution to obtain a nickel salt solution; 0.1208g Cu(NO 3 ) 2 ·3H 2 O is put into a beaker, and 10g of distilled water is added for ultrasonic dissolution to obtain a copper salt solution; then the gained nickel salt solution and copper salt solution are added dropwise to the mixed solution I, and magnetic stirring is perf...

Embodiment 3

[0066] A copper-doped Ni / SiO 2 Nano composite catalyst, its preparation method comprises the steps:

[0067] 1) Weigh 22.736g Na 2 SiO 3 9H 2 O was put into a beaker, and 75.024g of distilled water was added for ultrasonic dissolution to obtain Na 2 SiO 3 solution; dilute analytically pure concentrated nitric acid and distilled water at a volume ratio of 1:4 and add dropwise to the obtained Na 2 SiO 3 In the solution, magnetic stirring is carried out while adding dropwise, until pH=6, and mixed solution I is obtained;

[0068] 2) Weigh 2.617g Ni(NO 3 ) 2 ·6H 2 O was put into a beaker, and 13.833g of distilled water was added for ultrasonic dissolution to obtain a nickel salt solution; 0.2416g Cu(NO 3 ) 2 ·3H 2 O is put into a beaker, and 10 g of distilled water is added for ultrasonic dissolution to obtain a copper salt solution; then the obtained nickel salt solution and copper salt solution solution are added dropwise to the mixed solution I, and magnetic stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com