Method used for reinforced electric restoration of arsenic chromium composite polluted soil with reducing agent/chelating agent

A combined pollution and electric repair technology, applied in the field of soil remediation, can solve the problems of reducing the remediation rate and prolonging the remediation period, and achieves the effects of convenient operation, efficient removal and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

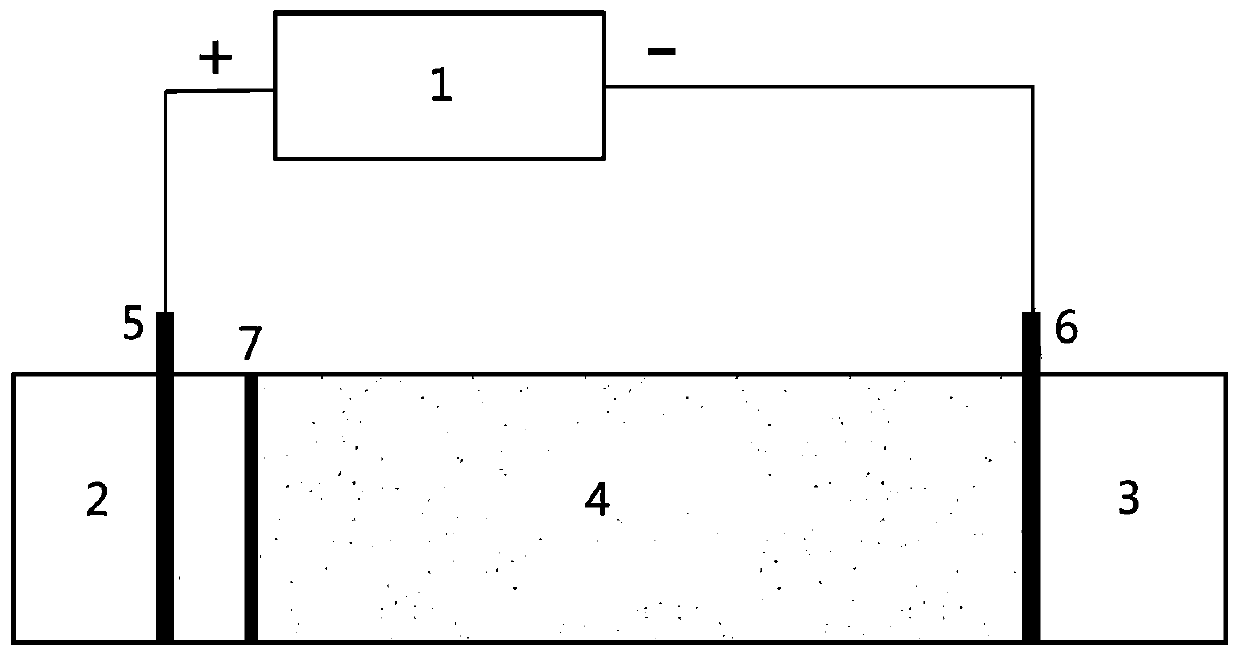

Image

Examples

Embodiment 1

[0020] A reducing agent / chelating agent strengthens the method for electrically repairing arsenic-chromium composite polluted soil, and its specific steps are as follows:

[0021] a. Air-dry 600g of arsenic-chromium composite polluted soil, crush it, remove gravel and plant residue, and pass through a 20-mesh sieve to obtain arsenic-chromium composite polluted soil powder, which is stored for later use;

[0022] b. 5.55g (50mmol) calcium chloride (CaCl 2 ) and 6.04g (25mmol) aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) Stir evenly to obtain a mixed solution; under the condition of filling nitrogen, slowly pour 50ml of sodium hydroxide (NaOH) solution into the above mixed solution while stirring, stir for 60min, and prepare a layered double hydroxide (CaCl 2 and AlCl 3 ·6H 2 (0) solution; then stirred at room temperature for 23 hours, then suction filtered, placed in a 105°C oven for drying, took out the solid sample, and then washed repeatedly with distilled water under ...

Embodiment 2

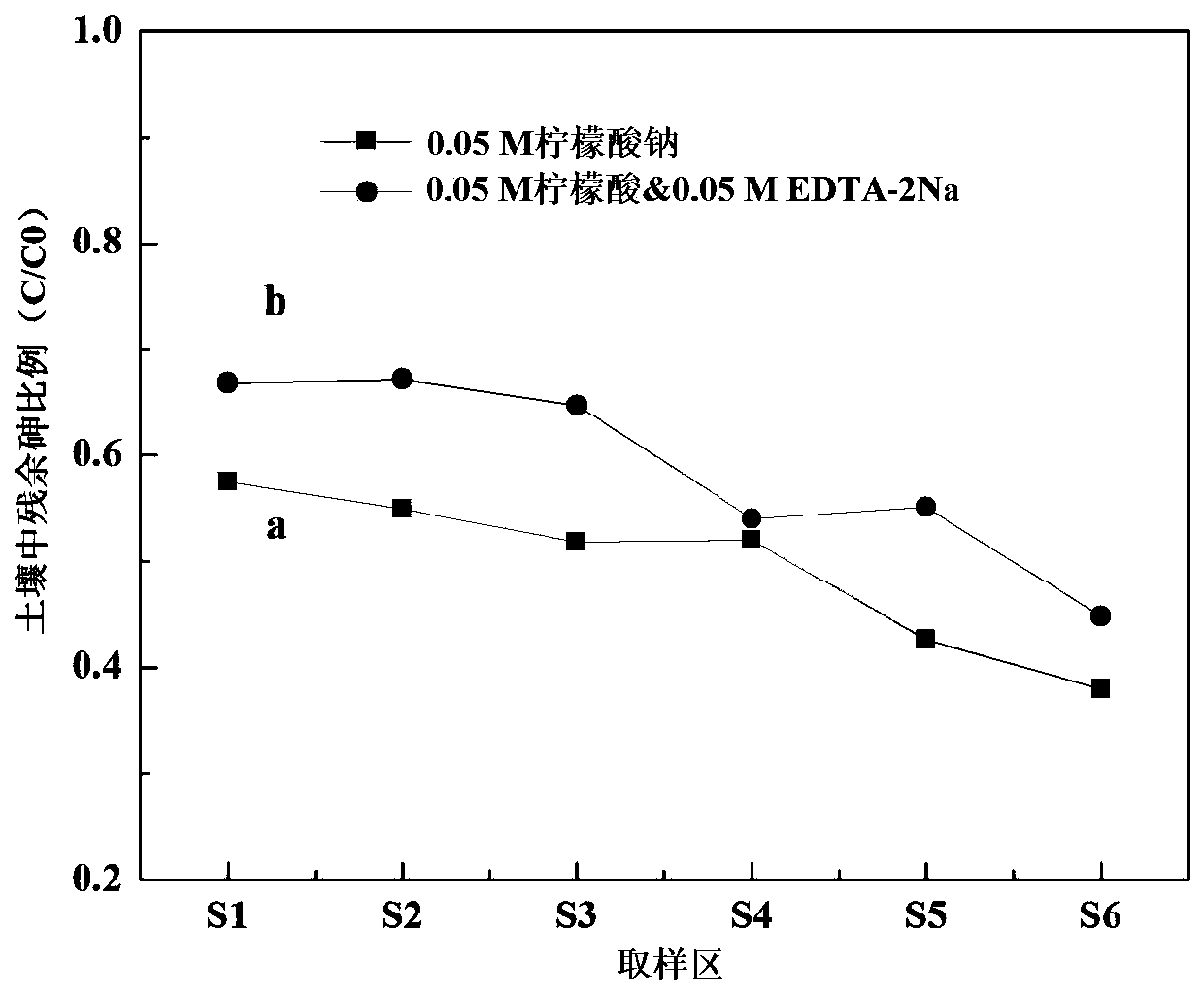

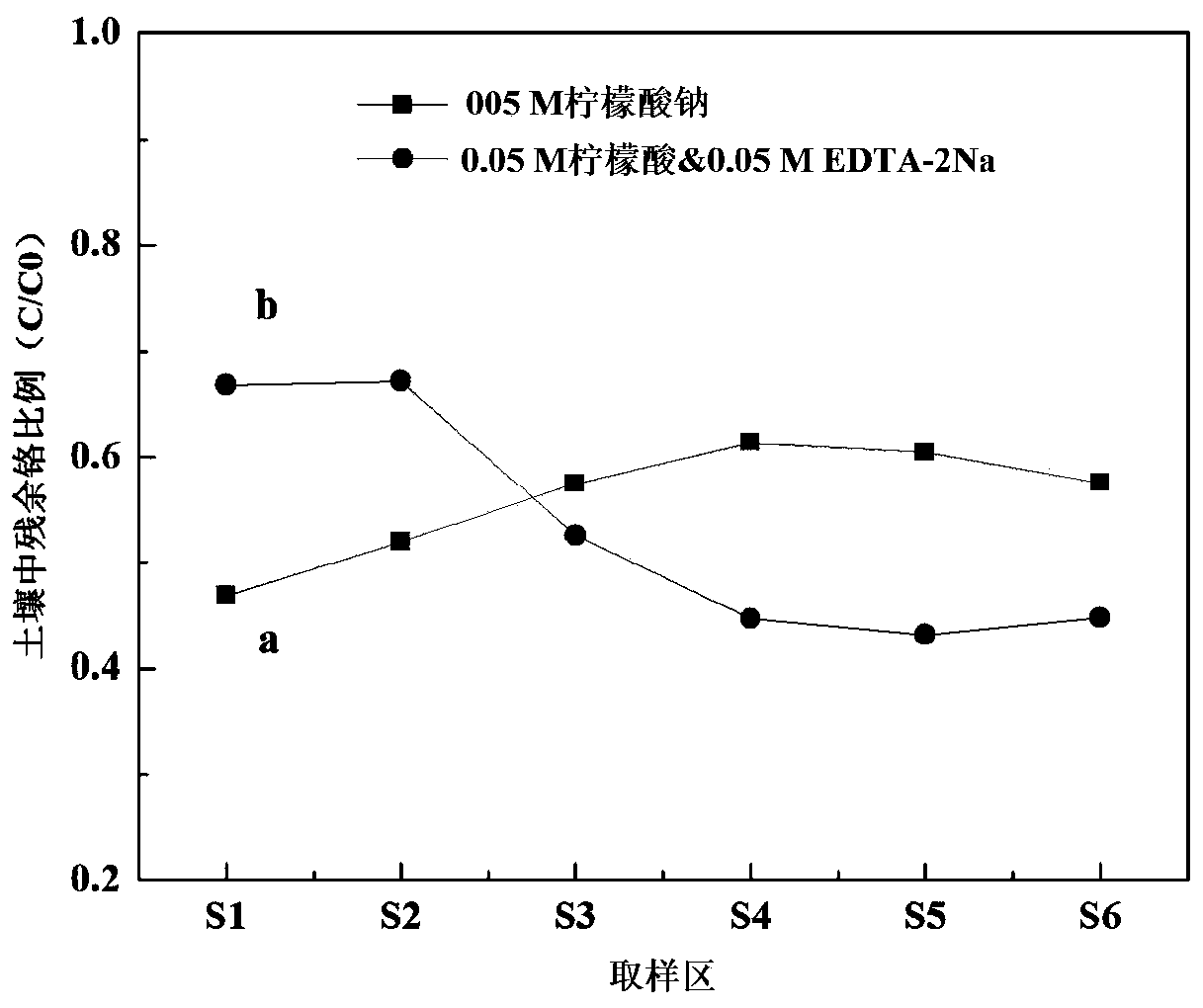

[0026] The method for remediating arsenic-chromium composite polluted soil in Example 2 is the same as Example 1, except that the reducing agent in step c in Example 2 is 0.05M citric acid combined with 0.05M EDTA-2Na. After the reaction, the average removal rates of arsenic and chromium in the repaired soil were determined to be 41.2% and 46.8%, respectively. from figure 2 (b) and image 3 (b) It can be seen that in the six sampling points from S1 to S6, the proportion of residual arsenic and chromium in the soil to the total amount of original arsenic and chromium (C / C 0 ) are less than 1, indicating that the arsenic-chromium composite polluted soil has been restored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com