Harmless recycling treatment system for waste salts

A treatment system and recycling technology, applied in the field of waste salt harmless recycling treatment system, can solve the problems of difficulty in adopting waste salt incineration technology by small and medium-sized enterprises, high investment and energy consumption of incinerators, and achieve short construction period and low operating cost. , to deal with the effect of simple system flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

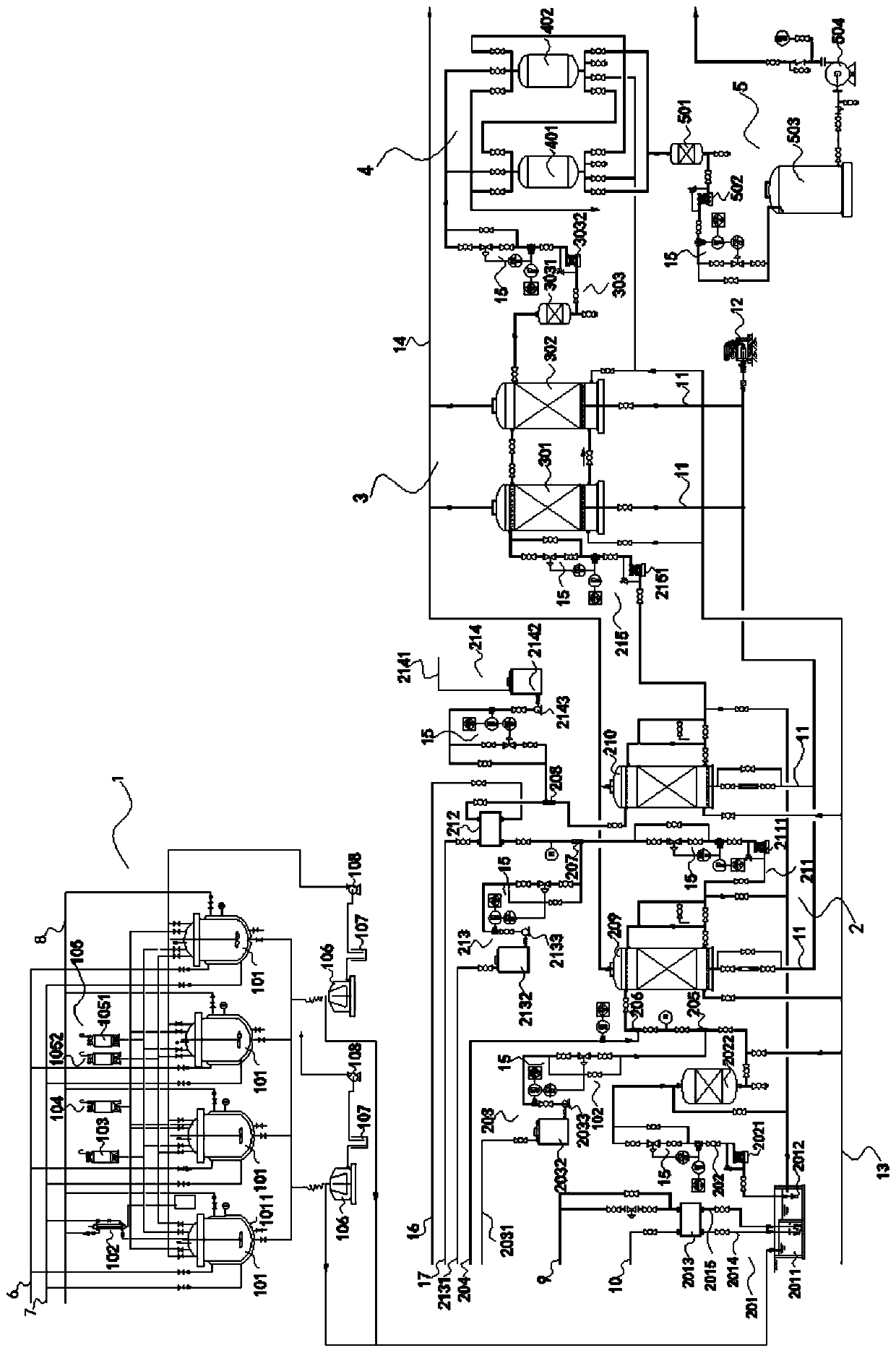

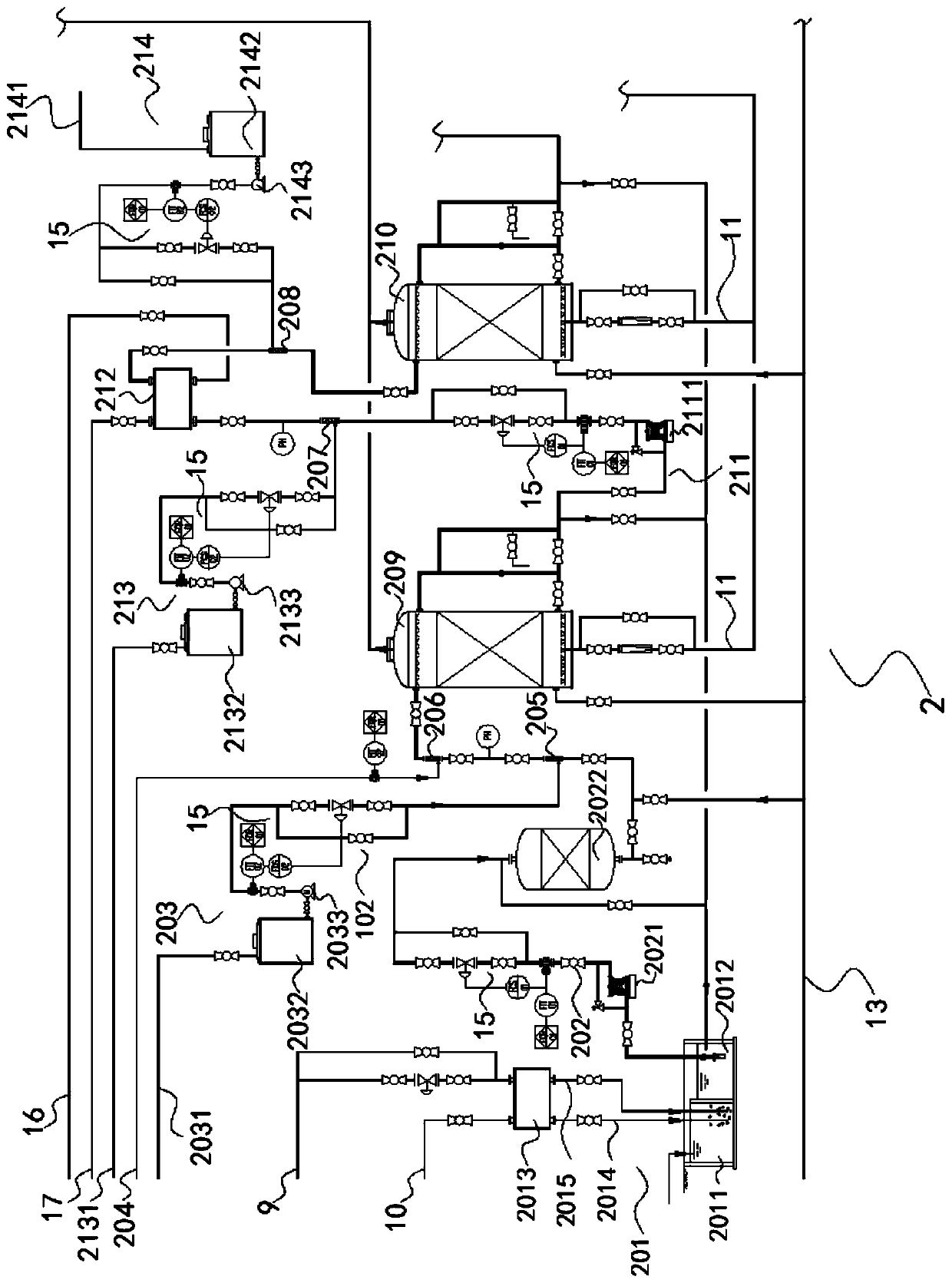

[0056] A waste salt harmless resource treatment system, such as Figure 1-5 As shown, it includes a primary oxidation refining system 1, a secondary two-stage oxidation refining system 2, an activated carbon tower adsorption system 3, a macroporous resin tower adsorption system 4, and a brine discharge system 5.

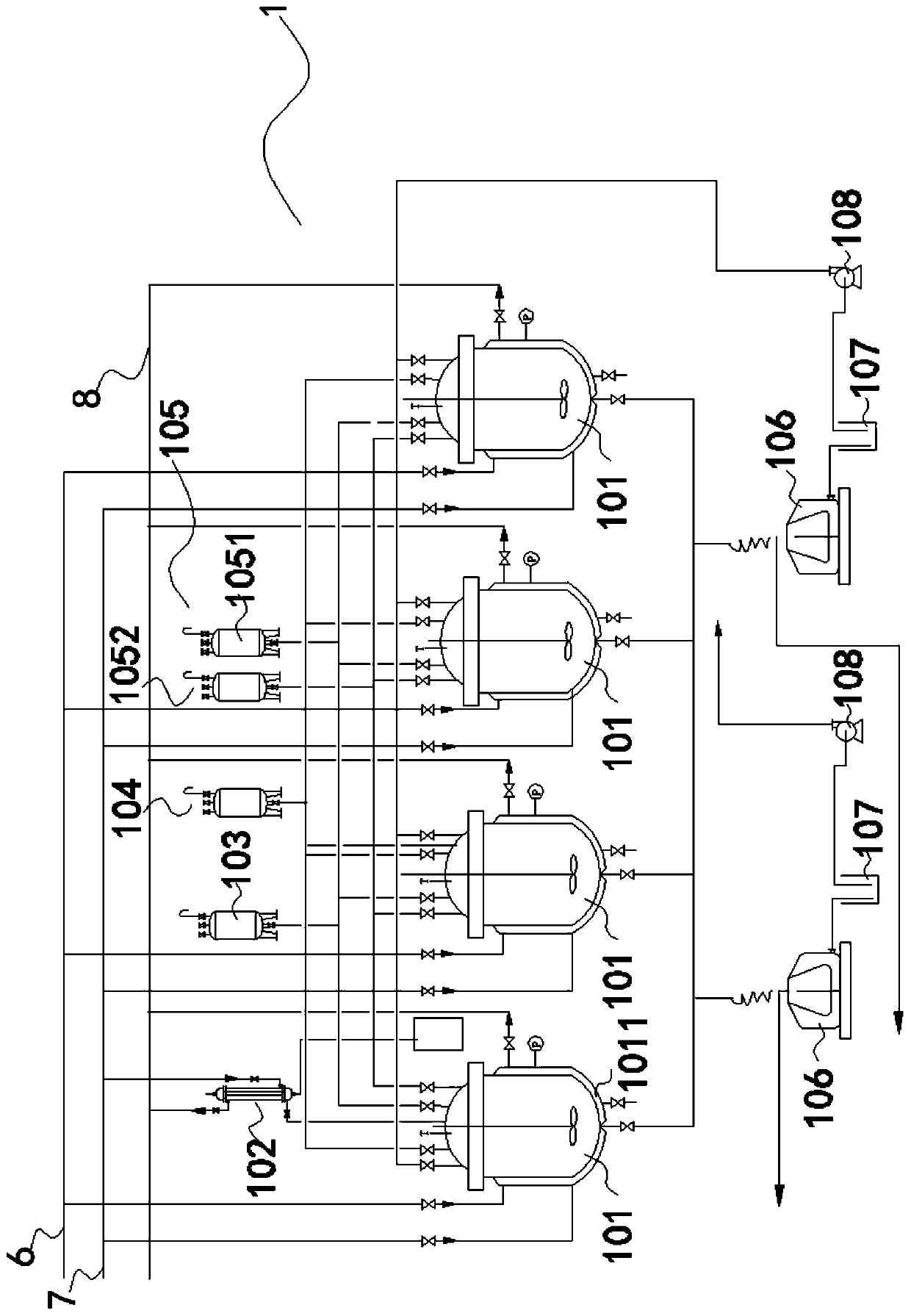

[0057] (1) Primary oxidation refining system 1

[0058] When waste salt is treated, it is first necessary to use the primary oxidation refining system 1 to perform primary oxidation and refining treatment on the waste salt solution. The primary oxidation refining system includes a waste salt treatment kettle 101 , a hydrogen peroxide storage tank 103 , a water storage tank 104 , a pH adjustment device 105 , a centrifugal filter 106 and a filtrate storage tank 107 .

[0059] The hydrogen peroxide storage tank 103, the water storage tank 104, and the pH adjustment device 105 are all connected to the waste salt treatment kettle through pipelines, wherein the pH adjustm...

Embodiment 2

[0098] A harmless resource treatment system for waste salt, comprising a primary oxidation refining system 1 and a secondary two-stage oxidation refining system 2, the composition of the primary oxidation refining system 1 and the secondary two-stage oxidation refining system 2 is the same as in Embodiment 1.

[0099] After the waste salt is successively treated by the primary oxidation refining system 1 and the secondary two-stage oxidation refining system 2, the waste brine obtained can be used as salt for ion membrane caustic soda or as industrial salt after further separation or purification.

[0100] The waste brine treated by the secondary two-stage oxidation refining system 2 can be discharged through the conventional brine discharge system, or can be discharged through the brine discharge system 5 in the present invention as in Example 1.

Embodiment 3

[0102] A harmless resource treatment system for waste salt, comprising a primary oxidation refining system 1, a secondary two-stage oxidation refining system 2, an activated carbon tower adsorption system 3, a primary oxidation refining system 1, a secondary two-stage oxidation refining system 2, and an activated carbon tower The composition of adsorption system 3 is the same as that of embodiment 1.

[0103] After the waste salt is successively treated by the primary oxidation refining system 1, the secondary two-stage oxidation refining system 2, and the activated carbon tower adsorption system 3, the waste salt water obtained can be used as salt for ion membrane caustic soda or as industrial salt after further separation or purification.

[0104] The waste brine treated by the activated carbon tower adsorption system 3 can be discharged through a conventional brine discharge system, or can be discharged through the brine discharge system 5 of the present invention in the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com