Environment-friendly modified polyurethane adhesive and preparation method thereof

A polyurethane adhesive and modification technology, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve environmental pollution and other problems, and achieve the effects of strong operability, mild conditions, and improved application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of above-mentioned environment-friendly modified polyurethane adhesive comprises the following steps:

[0032] 1) Control the reaction temperature to be 80°C, add polyester polyol and solvent in turn to the reaction kettle, mix and stir evenly;

[0033] 2) Control the reaction temperature at 82-85°C, add isocyanate and catalyst to the reaction kettle in sequence, mix and stir evenly, and react for 3-5 hours;

[0034] 3) Control the reaction temperature at 82-85°C, add chain extender, mix and stir evenly and continue to react for 1-3 hours;

[0035] 4) Control the reaction temperature at 80-82°C, add a terminator into the reactor, mix and stir evenly and continue the reaction for 1-2 hours;

[0036] 5) Add cellosolve into the reaction kettle, mix and stir evenly and continue to react for 1-2 hours;

[0037] 6) Control the reaction temperature below 50°C, add a viscosity regulator into the reaction kettle, mix and stir evenly, and then discharge. ...

Embodiment 1

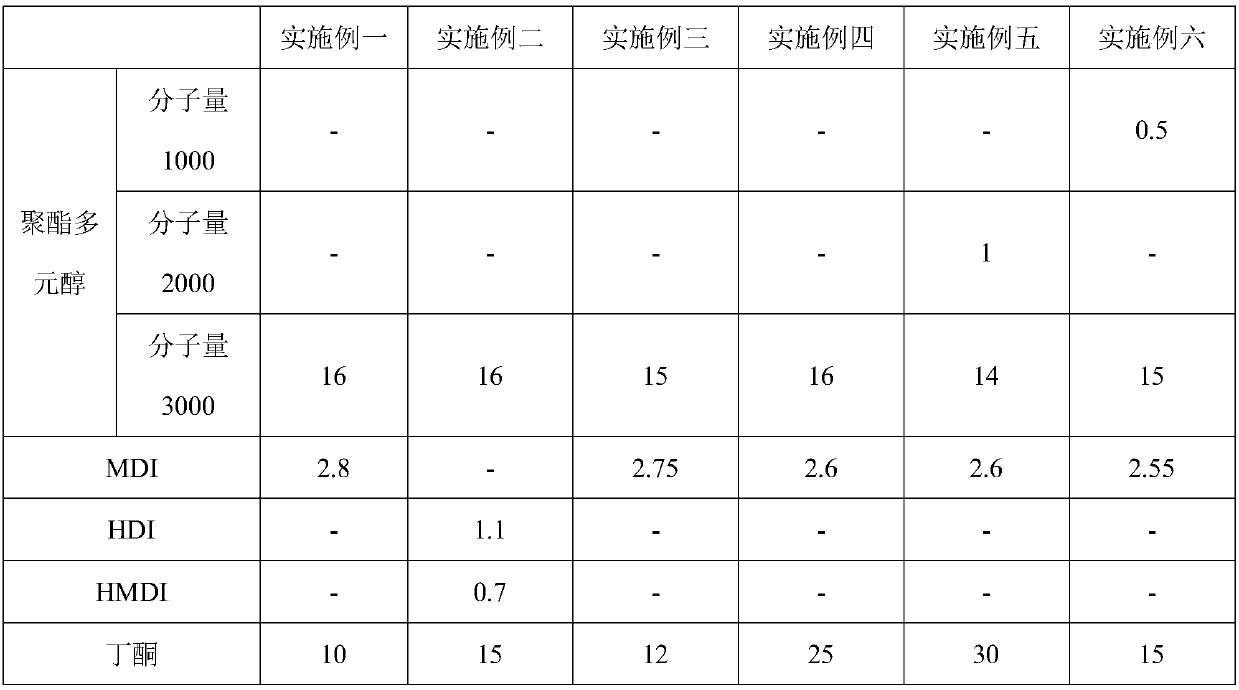

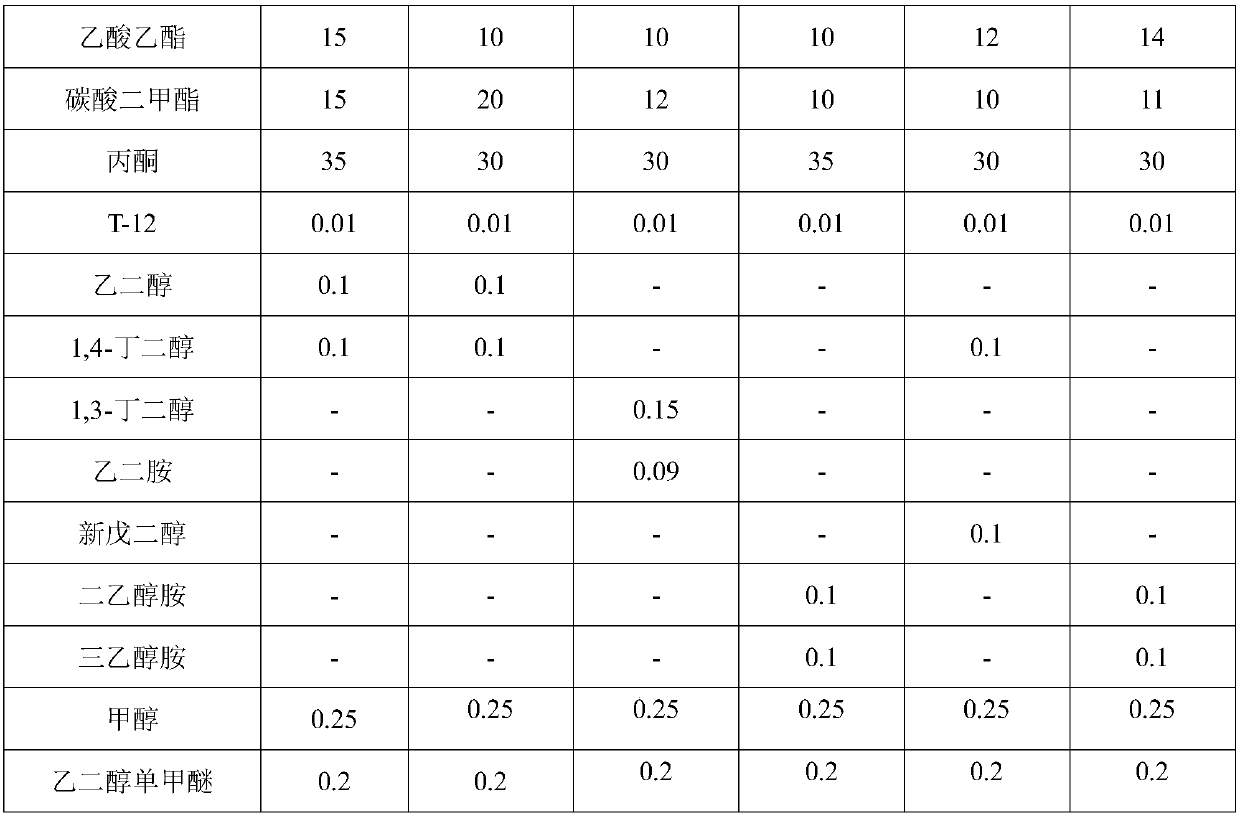

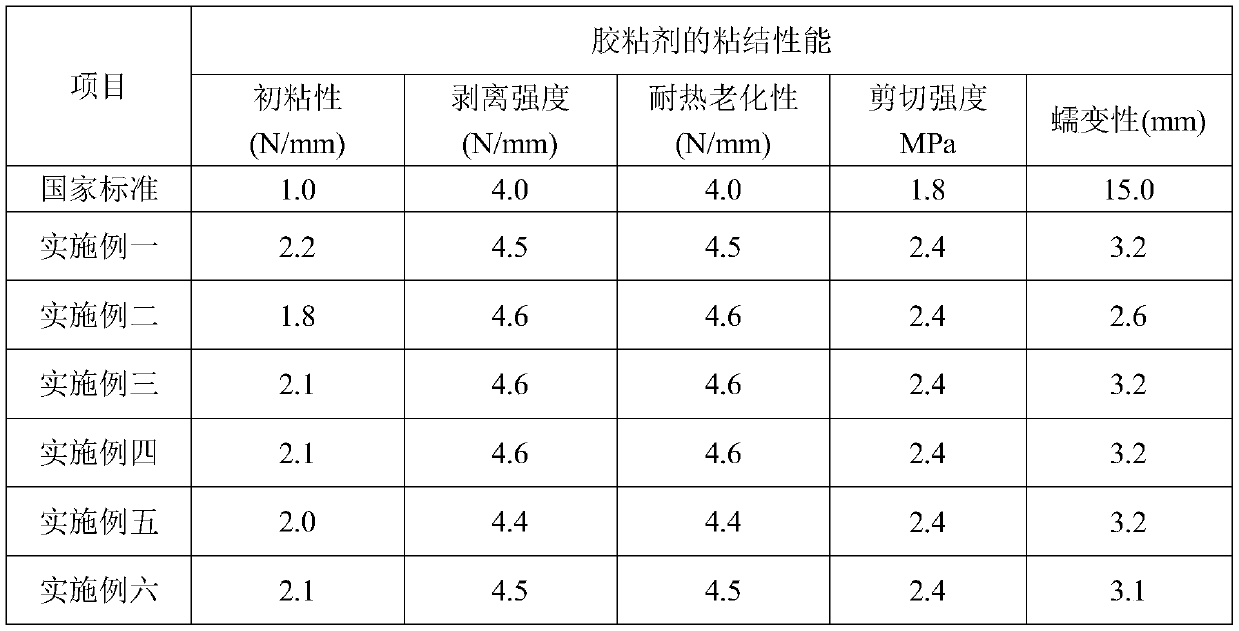

[0042] An environmentally friendly modified polyurethane adhesive, including polyester polyol, isocyanate, solvent, viscosity modifier, catalyst, chain extender, terminator and cellosolve, wherein the polyester polyol includes a polyester polyol with a molecular weight of 3000 ; The isocyanate adopts MDI; The solvent includes butanone, ethyl acetate and dimethyl carbonate; The viscosity modifier adopts acetone;

[0043] The catalyst is organic tin catalyst T-12; the chain extender includes ethylene glycol and 1,4-butanediol; the terminator is methanol. The content of each component is shown in Table 1.

[0044] The preparation method of environment-friendly modified polyurethane adhesive comprises the steps:

[0045] 1) Preheat the reaction kettle, control the reaction temperature to 80°C, add polyester polyol and solvent to the reaction kettle in turn, control the stirring speed to 80-100r / min, and mix and stir evenly;

[0046] 2) Heat up the reaction kettle, control the re...

Embodiment 2

[0052] The difference between embodiment two and embodiment one is that the isocyanate includes HDI and HMDI, and the contents of each component are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com