Processing process of corrosion-resistant aluminum-magnesium alloy

An aluminum-magnesium alloy, corrosion-resistant technology, applied in metal material coating process, coating and other directions, can solve problems such as inconvenience, reduced service life of aluminum-magnesium alloy, strength and corrosion resistance can not meet our needs, etc. The effect of avoiding agglomeration, enhancing strength and electrical conductivity, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] First prepare raw materials, weigh aluminum ingots, magnesium ingots, aluminum-chromium master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, electrolytic copper, zinc ingots, aluminum-manganese master alloys, aluminum-titanium master alloys, aluminum-lanthanum master alloys and Al-beryllium master alloy, spare; weigh graphene oxide in proportion, grind it in a ball mill for 20 minutes to obtain graphene oxide powder; Amide, for subsequent use; take hexadecyltrimethoxysilane and dodecyltrimethoxysilane in proportion, and mix them uniformly to obtain modifier, for subsequent use;

[0058] Then prepare the alloy matrix, take the aluminum ingot and place it in the furnace, heat up to 660°C, then add graphene oxide powder, stir for 20 minutes, then add aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy, keep warm for 20 minutes, and then heat up To 740°C, add magnesium ingots, aluminum-chromium master alloys,...

Embodiment 2

[0063]First prepare raw materials, weigh aluminum ingots, magnesium ingots, aluminum-chromium master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, electrolytic copper, zinc ingots, aluminum-manganese master alloys, aluminum-titanium master alloys, aluminum-lanthanum master alloys and Al-beryllium master alloy, spare; weigh graphene oxide in proportion, grind it in a ball mill for 25 minutes, and obtain graphene oxide powder; Amide, for subsequent use; take hexadecyltrimethoxysilane and dodecyltrimethoxysilane in proportion, and mix them uniformly to obtain modifier, for subsequent use;

[0064] Then prepare the alloy matrix, take the aluminum ingot and put it in the furnace, heat up to 670°C, then add graphene oxide powder, stir for 23 minutes, then add aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy, keep it warm for 25 minutes, and then raise the temperature To 750°C, add magnesium ingots, aluminum-chromiu...

Embodiment 3

[0069] First prepare raw materials, weigh aluminum ingots, magnesium ingots, aluminum-chromium master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, electrolytic copper, zinc ingots, aluminum-manganese master alloys, aluminum-titanium master alloys, aluminum-lanthanum master alloys and Al-beryllium master alloy, spare; weigh graphene oxide in proportion, grind it in a ball mill for 30 minutes, and obtain graphene oxide powder; Amide, for subsequent use; take hexadecyltrimethoxysilane and dodecyltrimethoxysilane in proportion, and mix them uniformly to obtain modifier, for subsequent use;

[0070] Then prepare the alloy matrix, take the aluminum ingot and put it in the furnace, heat up to 680°C, then add graphene oxide powder, stir for 25 minutes, then add aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy, keep warm for 30 minutes, and then heat up to 760°C, add magnesium ingots, aluminum-chromium master alloys,...

PUM

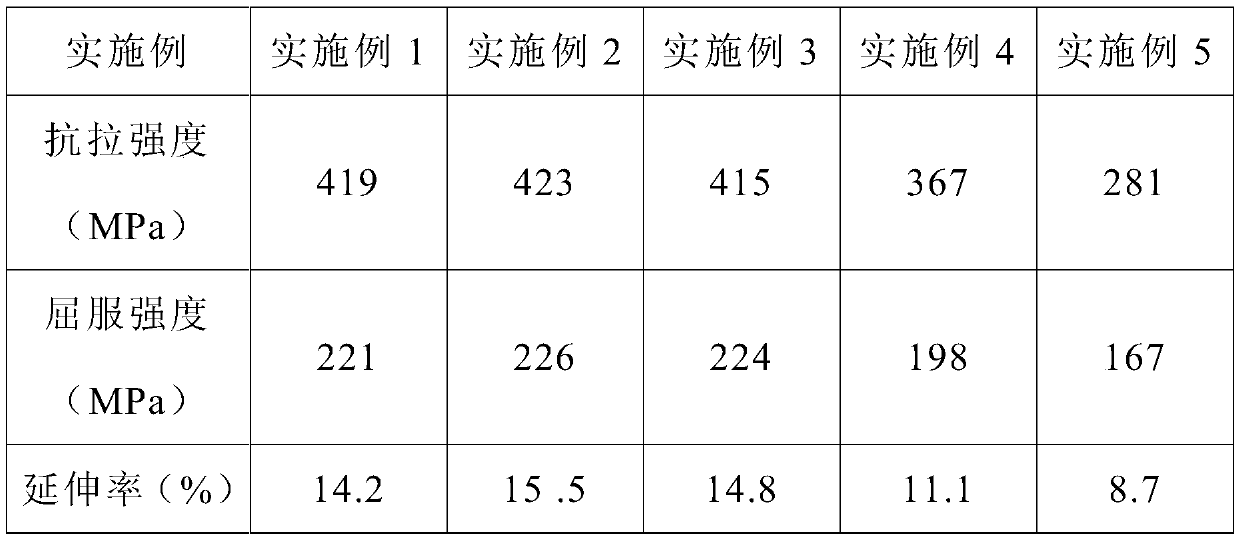

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com