Low-noise and high-temperature-resisting drum type friction plate produced through three-layer materials and preparing method of low-noise and high-temperature-resisting drum type friction plate

A technology of friction plate and high temperature resistance, which is applied in the field of friction materials, can solve the problems of reduced braking performance, accelerated wear, braking noise and high temperature resistance, and achieves long service life, high temperature resistance, good The effect of noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

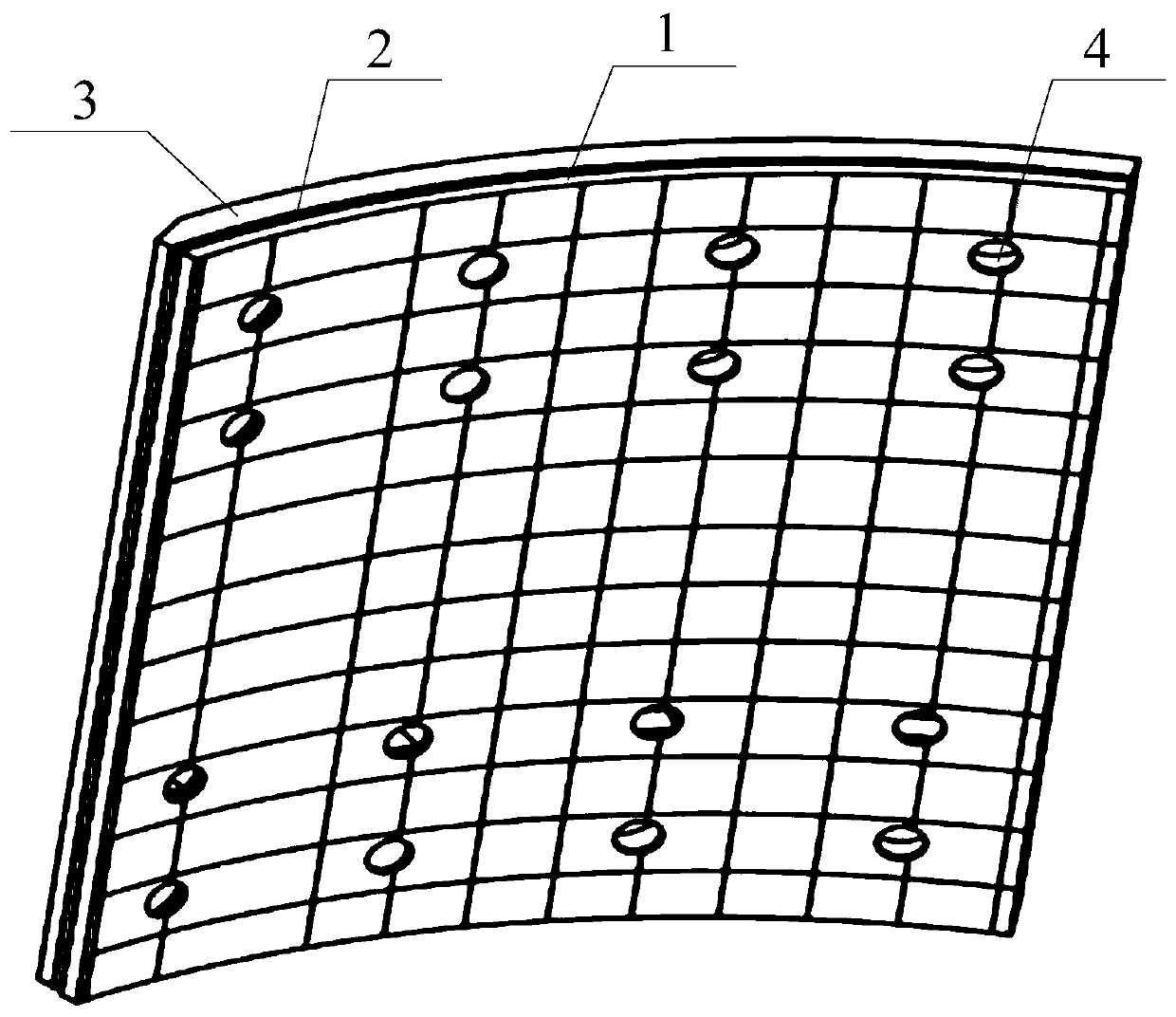

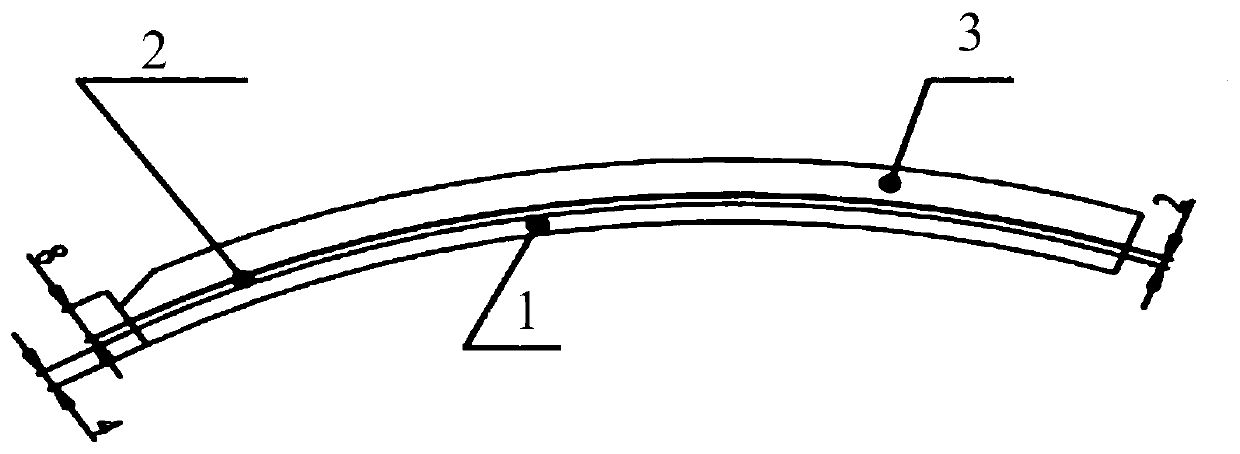

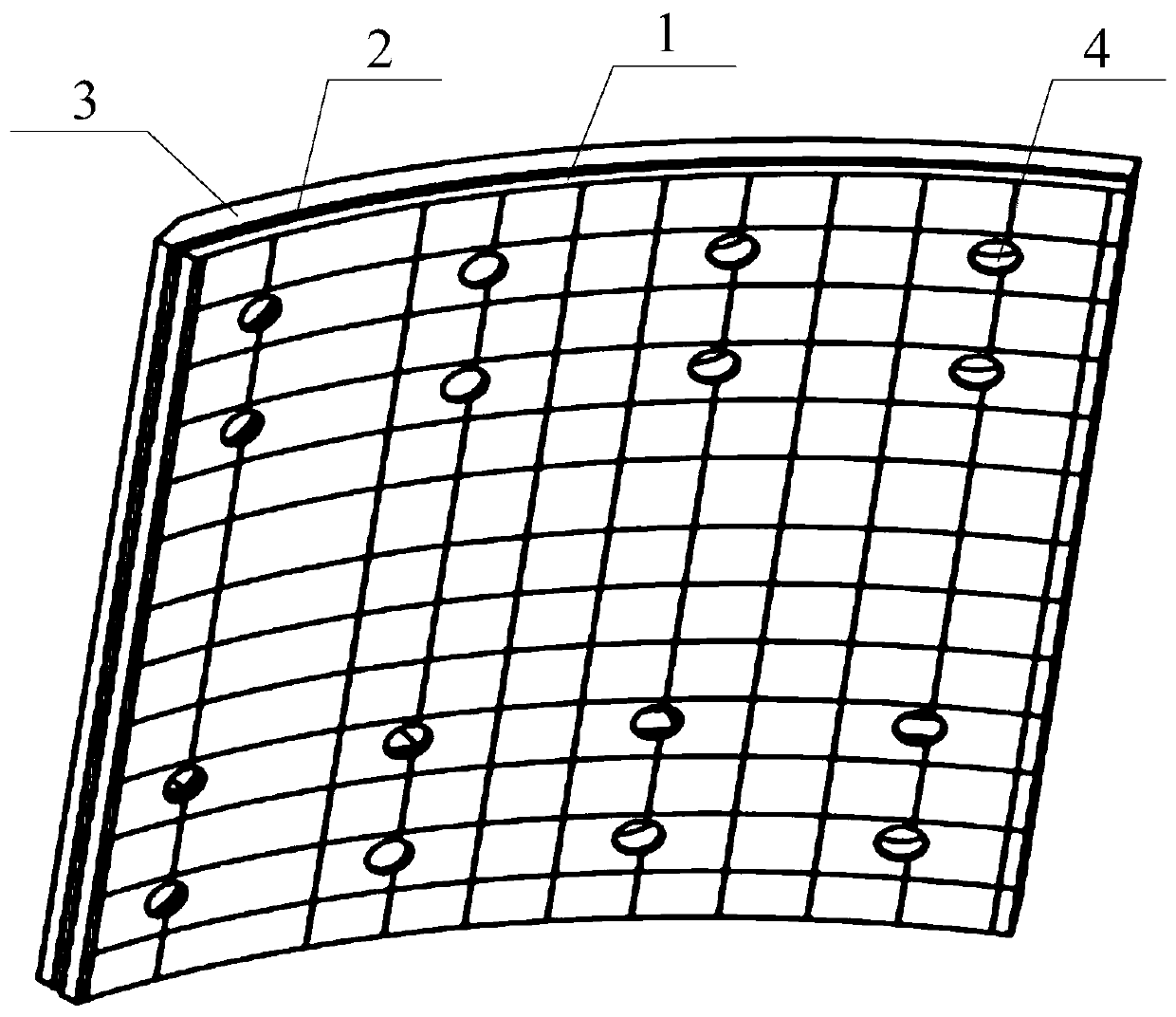

[0030] Such as figure 1 and figure 2 As shown, it is a low-noise and high-temperature-resistant drum friction plate produced by three-layer materials provided by the present invention. The drum friction plate includes a fabric layer 3, a shock-absorbing layer 2 and a primer layer 1. The fabric layer 3. Both the damping layer 2 and the primer layer 1 are provided with corresponding through holes 4, through which bolts pass through the through holes 4 to fix the drum friction plate.

[0031] The low-noise and high-temperature-resistant drum friction plate can be prepared by the following method:

[0032] 1) Put the mixed base material layer premix, shock absorbing layer premix, and fabric layer premix into the hot pressing mold in sequence according to the weight ratio of 1.5:1:3. Under the pressure of 16MPa, the temperature of 200℃ Curing for 8 minutes;

[0033] 2) Put the hot-pressed semi-finished product into a heat treatment furnace for heat treatment, wherein the heat t...

Embodiment 2

[0053] The low-noise and high-temperature-resistant drum friction plate can be prepared by the following method:

[0054] 1) Put the mixed base material layer premix, shock absorbing layer premix, and fabric layer premix into the hot pressing mold in sequence according to the weight ratio of 1.5:1:3. Under the pressure of 18MPa, the temperature of 200℃ Curing for 10 minutes;

[0055] 2) Put the hot-pressed semi-finished product into a heat treatment furnace for heat treatment, wherein the heat treatment temperature is 180°C, and the time is 10 hours;

[0056] 3) Grinding the heat-treated semi-finished products into finished products according to the drawings.

[0057] In this embodiment, the material of the friction material fabric layer includes by weight: 10 parts of polyimide resin, 4 parts of polyacrylonitrile fiber, 2 parts of aramid fiber, 8 parts of basaltic mineral fiber, potassium titanate crystal 15 parts of whiskers, 10 parts of calcium sulfate whiskers, 5 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com