Non-noble metal catalyst and preparation method thereof

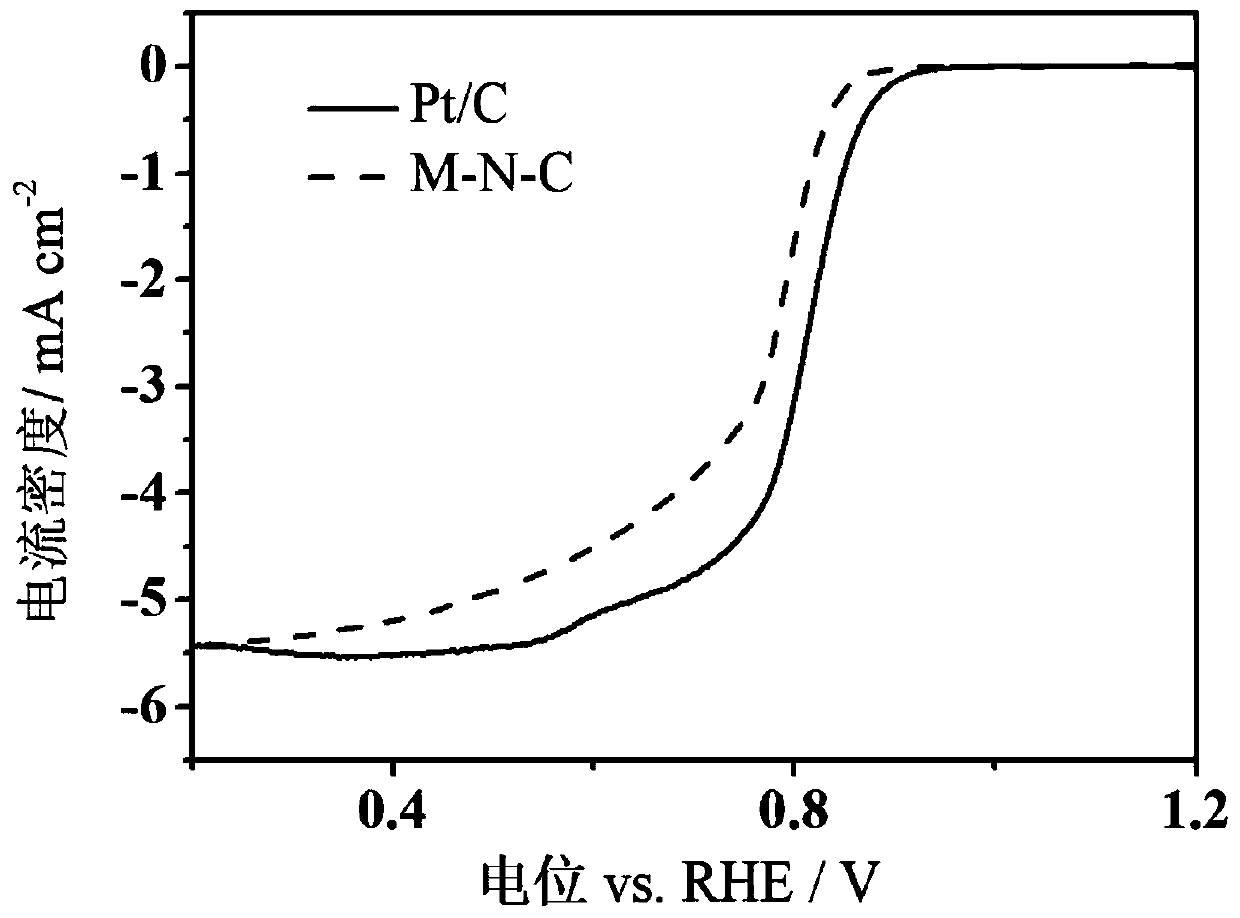

A non-precious metal and catalyst technology, applied in the field of electrochemical energy, can solve the problems of catalytic activity gap and low catalytic activity, and achieve the effects of low cost, good catalytic performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

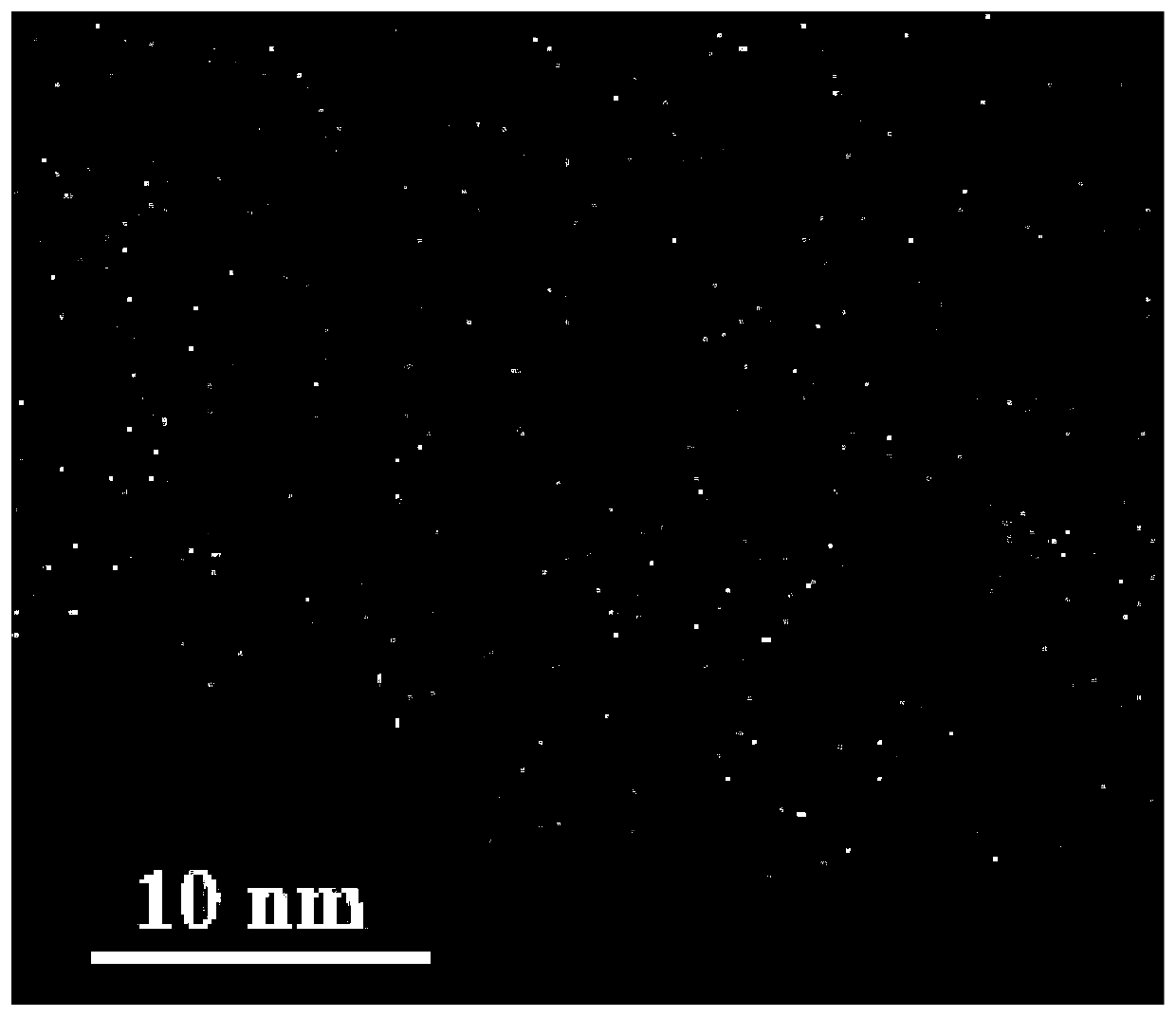

[0066] Aromatic nitrile (isophthalonitrile) and metal oxide nanoparticles (Fe 2 o 3 Nanorods, particle size 30-300nm) are dry-blended at a molar ratio of 3:1, the dry-blended sample is protected under inert conditions (nitrogen), and the inorganic salt of Lewis acid (chlorinated Zinc) after grinding, transferred to a 14mL airtight device (sealed quartz tube) under the protection of inert gas (nitrogen). Then put it in a muffle furnace, heat up to 700°C at a heating rate of 5°C / min and heat for 24 hours, take it out and grind it, add 0.1M hydrochloric acid solution, pickle at 80°C for 12 hours, suction filter, wash with water, and dry to obtain non-precious metals Catalyst, recorded as sample 1#.

Embodiment 2

[0068] Aromatic nitrile (isophthalonitrile) and metal oxide nanoparticles (Fe 2 o 3 Nanorods, particle size 30-300nm) are dry-blended at a molar ratio of 4:1, the dry-blended sample is protected under inert conditions (nitrogen), and the inorganic salt of Lewis acid (chlorinated Zinc) after grinding, transferred to a 14mL airtight device (sealed quartz tube) under the protection of inert gas (nitrogen). Then put it in a muffle furnace, heat up to 700°C at a heating rate of 5°C / min and heat for 24 hours, take it out and grind it, add 0.1M hydrochloric acid solution, pickle at 80°C for 12 hours, suction filter, wash with water, and dry to obtain non-precious metals Catalyst, denoted as sample 2#.

Embodiment 3

[0070] Aromatic nitrile (isophthalonitrile) and metal oxide nanoparticles (Fe 2 o 3 Nanorods, particle size 30-300nm) are dry-blended at a molar ratio of 2:1, the dry-blended sample is protected under inert conditions (nitrogen), and the inorganic salt of Lewis acid (chlorinated Zinc) after grinding, transferred to a 14mL airtight device (sealed quartz tube) under the protection of inert gas (nitrogen). Then put it in a muffle furnace, heat up to 700°C at a heating rate of 5°C / min and heat for 24 hours, take it out and grind it, add 0.1M hydrochloric acid solution, pickle at 80°C for 12 hours, suction filter, wash with water, and dry to obtain non-precious metals Catalyst, denoted as sample 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com