Hydrocalumite derived cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid

A cobalt-based catalyst and autothermal reforming technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrogen, etc., can solve problems such as carbon deposition and catalyst deactivation, and achieve improved Catalytic activity, beneficial to transfer and diffusion, and the effect of inhibiting condensation and carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

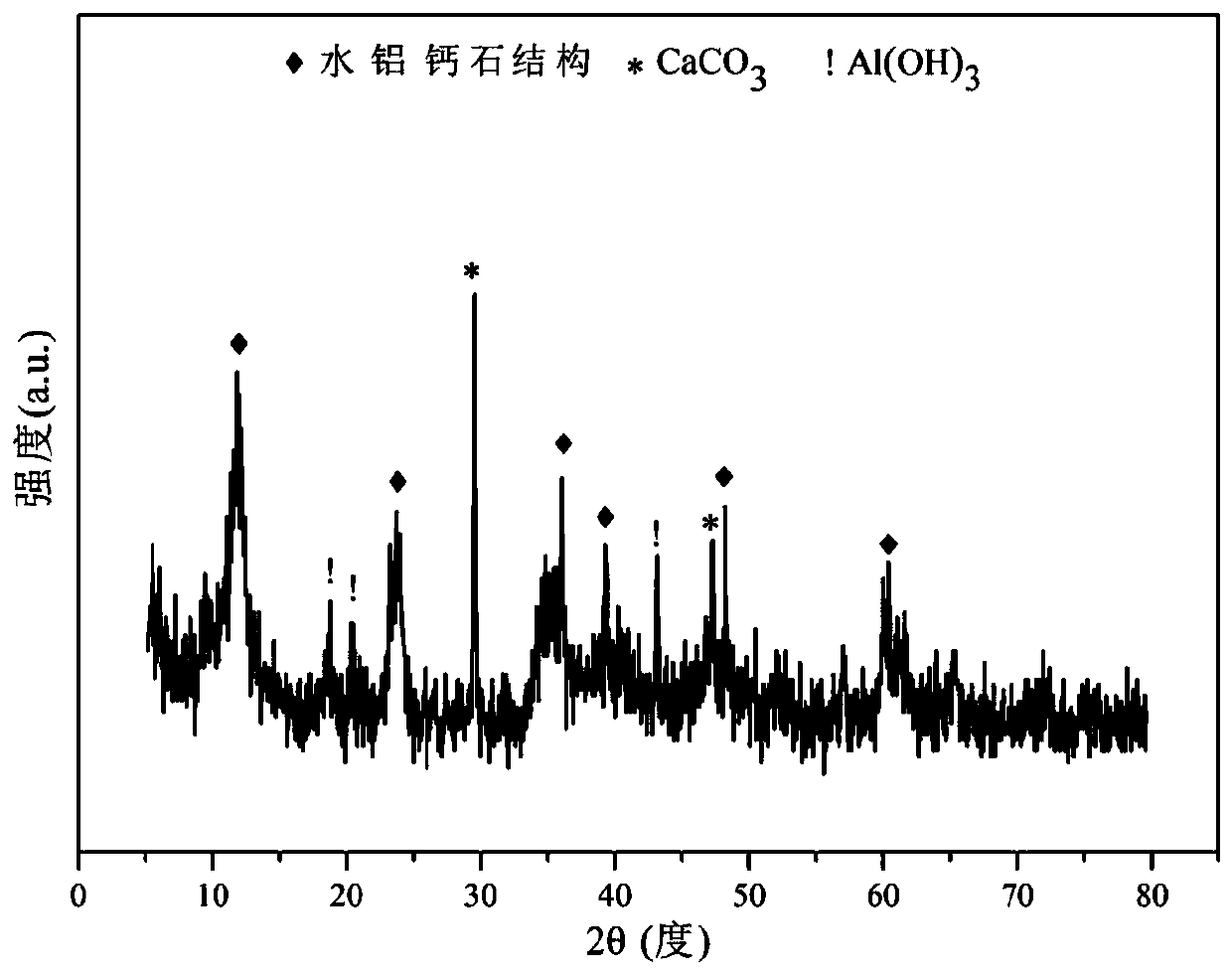

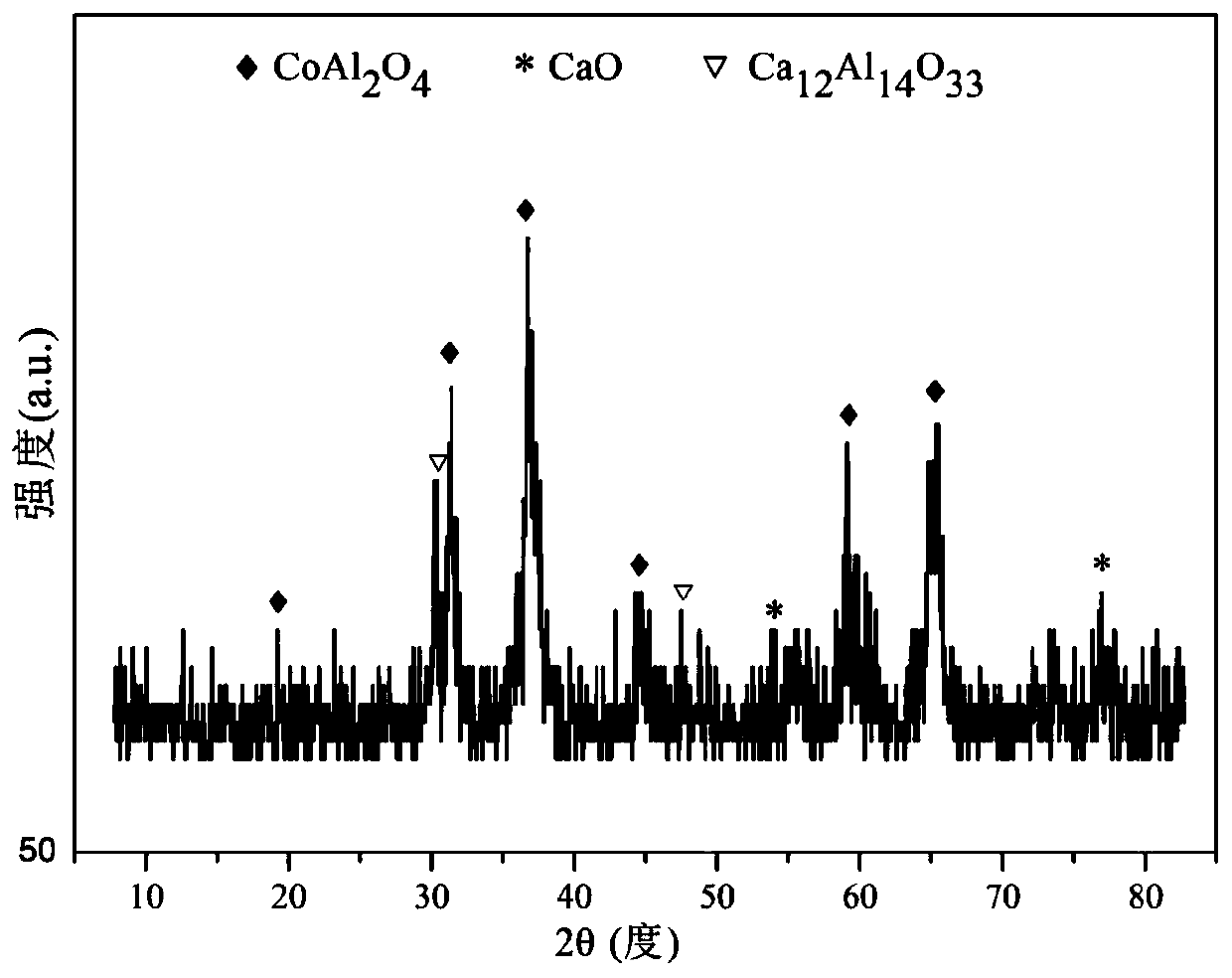

[0035] Weigh 11.329g of Ca(NO 3 ) 2 4H 2 O, 2.320g of Co(NO 3 ) 2 ·6H 2 O and 5.246g of Al(NO 3 ) 3 9H 2 O, add 69.9mL of deionized water to prepare solution #1; weigh 22.374g of NaOH and 3.705g of anhydrous Na 2 CO 3 , adding 148.6mL of deionized water to prepare solution #2; the subsequent steps are the same as in Reference Example 1, and a precursor with a hydrocalumite structure is obtained, containing a small amount of CaCO 3 and Al(OH) 3 , its typical structure is attached figure 1 Shown; Ca-Co-Al-O mesoporous composite oxide was obtained after calcination, the catalyst is based on calcium oxide, contains cobalt-aluminum spinel phase and a small amount of Ca 12 al 14 o 33 , its typical structure is attached figure 2 As shown, the CDUT-CCA-102 catalyst is obtained; the weight percent composition of the catalyst is: calcium oxide is 67.3%, cobalt oxide is 14.9%, and aluminum oxide is 17.8%.

[0036] The activity of the CDUT-CCA-102 catalyst was investigated...

Embodiment 2

[0038] Weigh 13.113g of Ca (NO 3 ) 2 4H 2 O, 2.190g of Co(NO 3 ) 2 ·6H 2 O and 4.122g of Al(NO 3 ) 3 9H 2 O, add 69.8mL of deionized water to prepare solution #1; weigh 22.335g of NaOH and 3.699g of anhydrous Na 2 CO 3 , add 148.3mL of deionized water to prepare solution #2; the subsequent steps are the same as in Reference Example 1, and the precursor of hydrocalumite structure is obtained, which contains a small amount of CaCO 3 and Al(OH) 3 , its typical structure is attached figure 1 As shown, the Ca-Co-Al-O mesoporous composite oxide was obtained after calcination. The catalyst uses calcium oxide as the skeleton, contains cobalt-aluminum spinel phase and a small amount of Ca 12 al 14 o 33 , its typical structure is attached figure 2 As shown, the CDUT-CCA-103 catalyst is obtained; the weight percent composition of the catalyst is: calcium oxide is 71.6%, cobalt oxide is 14.1%, and aluminum oxide is 14.3%.

[0039]The activity of the CDUT-CCA-103 catalyst w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com