Microsphere silicate-1 molecular sieve catalyst and preparation method thereof and method for preparing caprolactam

A technology of molecular sieve and catalyst, which is applied in the field of caprolactam preparation, can solve the problems such as the spray molding of Silicalite-1 molecular sieve, and achieve the effects of reduced product separation energy consumption, high total selectivity and total yield, and improved technical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

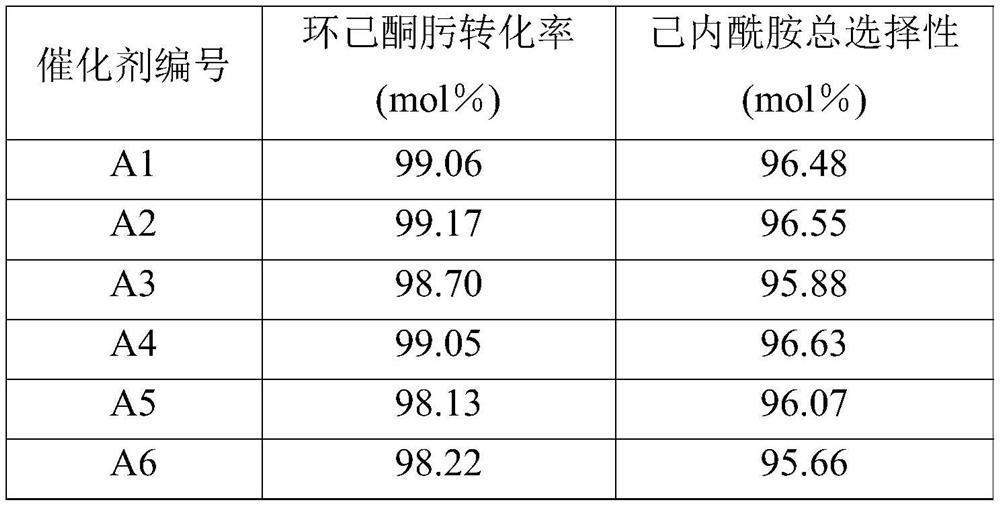

Examples

Embodiment 1

[0076] 416kg of ethyl orthosilicate, 360kg of 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 56.2g of Fe (NO 3 ) 3 ·9H 2 O and 415kg of water were mixed, and stirred at room temperature for 5 hours to form a colloidal mixture with a pH value of 12.8. In the mixture, SiO 2 :TPAOH:H 2 O (molar ratio) = 1:0.2:20, SiO 2 with Fe 3+ The weight ratio of 15347:1, move the above mixture into 2m 3 In a stainless steel reaction kettle, crystallize at 100 °C for 3 days, the pH value of the crystallization product is 13.57, then use a 50nm six-tube membrane for membrane filtration and wash with water at 40-60 °C, and the amount of washing water is 6.8m 3 The pH of the post-crystallized product reached 9.1. The slurry obtained after washing was concentrated to obtain 395 kg of molecular sieve slurry with a solid content of 26.8% by weight. A small amount of the molecular sieve slurry was dried at 120°C for 20 hours to obtain the original Silicate-1 molecular...

Embodiment 2

[0081] 416kg of ethyl orthosilicate, 360kg of 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 0.236kg of Al (NO 3 ) 3 ·9H 2 O and 410kg of water were mixed, and stirred at room temperature for 5 hours to form a colloidal mixture with a pH value of 12.35. In the mixture, SiO 2 :TPAOH:H 2 O (molar ratio) = 1:0.2:20, SiO 2 with Al 3+ The weight ratio of 7067:1, the above mixture was moved into 2m 3 In a stainless steel reaction kettle, crystallize at 100 °C for 3 days, the pH value of the crystallization product is 13.71, then use a 50nm six-tube membrane for membrane filtration and wash with water at 40 to 60 °C, and the amount of washing water is 6.6m 3 The pH of the post-crystallized product reached 9.0. The slurry obtained after washing was concentrated to obtain 436 kg of molecular sieve slurry with a solid content of 24.5% by weight. A small amount of the molecular sieve slurry was dried at 120°C for 20 hours to obtain the original Silicate-1...

Embodiment 3

[0086] 416kg of tetraethyl orthosilicate, 360kg of 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 8.4g of ZrOCl 2 ·8H 2 Mix O and 420kg of water, and stir at room temperature for 5 hours to form a colloidal mixture with a pH value of 12.46. In the mixture, SiO 2 :TPAOH:H 2 O (molar ratio) = 1:0.2:20, SiO 2 with Zr 4+ The weight ratio of 50596:1, the above mixture was moved into 2m 3 In a stainless steel reaction kettle, crystallize at 100°C for 3 days, the pH value of the crystallization product is 13.42, then use a 50nm six-tube membrane for membrane filtration and wash with water at 40-60°C, and the amount of washing water is 6.7m 3 The pH of the post-crystallized product reached 9.1. The slurry obtained after washing was concentrated to obtain 380 kg of molecular sieve slurry with a solid content of 28.4% by weight. A small amount of the molecular sieve slurry was dried at 120°C for 20 hours to obtain the original Silicate-1 molecular sieve p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com