Method for integrating polyurethane film on PDMS-based microfluidic structure

A microfluidic structure, integrated polyurethane technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems affecting the fineness and integrity of microstructures, unfavorable microfluidic chip preparation, complicated steps and other problems, to achieve the effect of low cost, good air tightness and outstanding elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

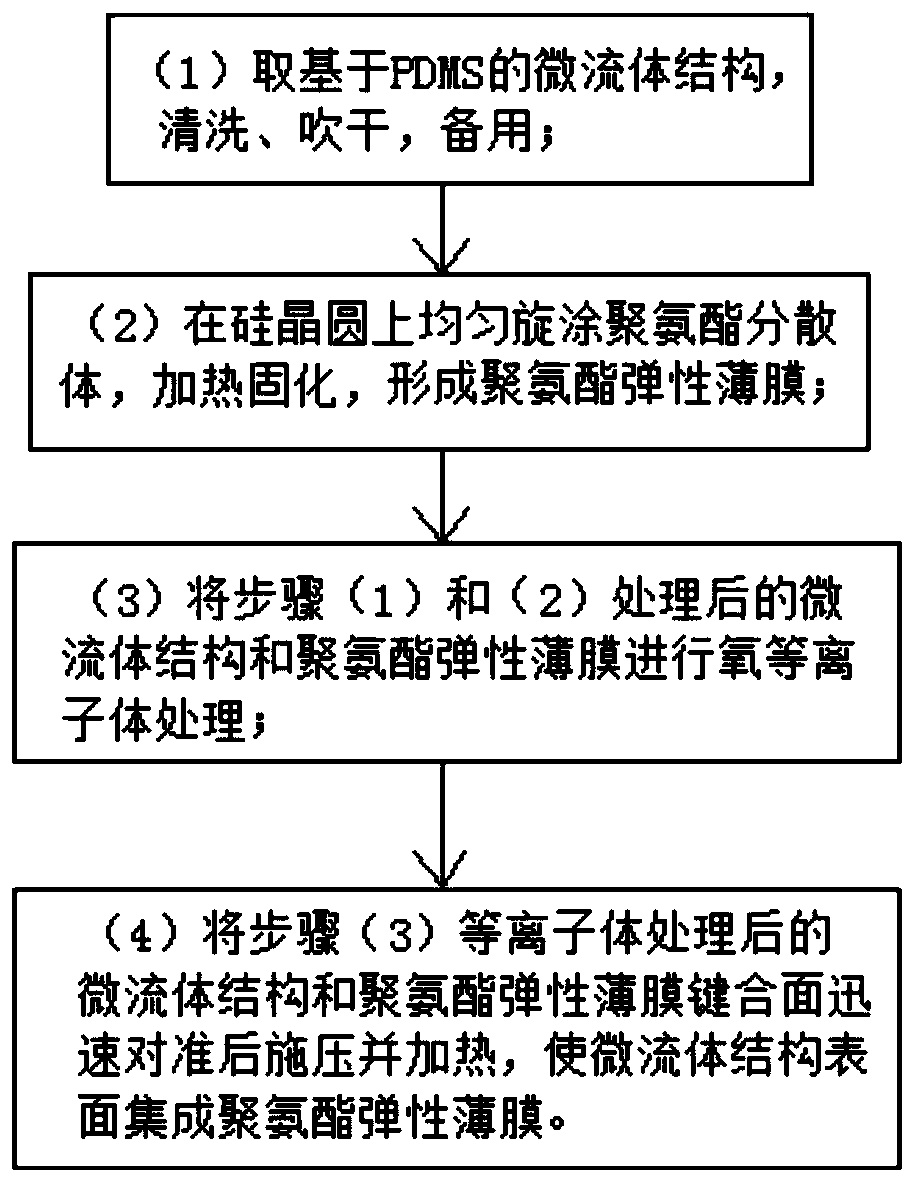

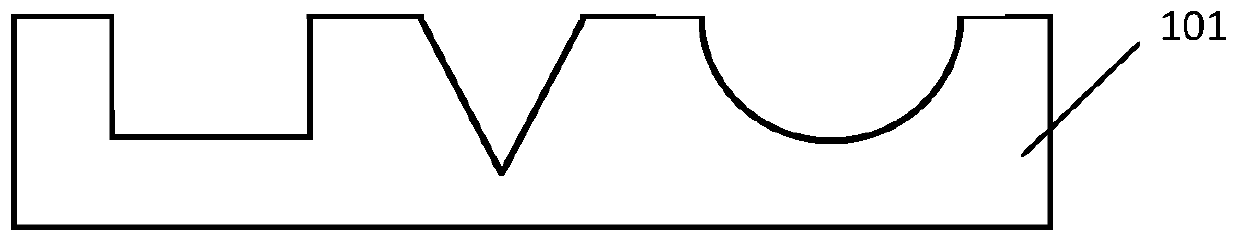

[0021] Such as Figure 1-5 As shown, this embodiment is based on the method of integrating a polyurethane film on a PDMS microfluidic structure, including the following steps:

[0022] (1) Take the PDMS-based microfluidic structure 101, clean it, dry it, and set it aside. The cleaning method is to clean it with isopropanol first, and then use deionized water to rinse the residual liquid on the surface. Blow dry with a nitrogen gun.

[0023] (2) Uniformly spin-coat the polyurethane dispersion on the silicon wafer, heat and solidify to form the polyurethane elastic film 102, wherein the polyurethane dispersion is an anionic water-based aliphatic polyurethane dispersion with a solid content greater than 35%.

[0024] (3) The microfluidic structure 101 and the polyurethane elastic film 102 processed in steps (1) and (2) are subjected to plasma treatment, wherein the plasma treatment method is to put the microfluidic structure 101 and the polyurethane elastic film 102 into Oxygen...

Embodiment 2

[0027] Such as Figure 1-5 As shown, this embodiment is based on the method of integrating a polyurethane film on a PDMS microfluidic structure, including the following steps:

[0028] (1) Take the PDMS-based microfluidic structure 101, clean it, dry it, and set it aside. The cleaning method is to clean it with isopropanol first, and then use deionized water to rinse the residual liquid on the surface. Blow dry with a nitrogen gun.

[0029] (2) Uniformly spin-coat the polyurethane dispersion on the silicon wafer, heat and solidify to form the polyurethane elastic film 102, wherein the polyurethane dispersion is an anionic water-based aliphatic polyurethane dispersion with a solid content greater than 35%.

[0030] (3) The microfluidic structure 101 and the polyurethane elastic film 102 processed in steps (1) and (2) are subjected to plasma treatment, wherein the plasma treatment method is to put the microfluidic structure 101 and the polyurethane elastic film 102 into Oxygen...

Embodiment 3

[0033] Such as Figure 1-5 As shown, this embodiment is based on the method of integrating a polyurethane film on a PDMS microfluidic structure, including the following steps:

[0034] (1) Take the PDMS-based microfluidic structure 101, clean it, dry it, and set it aside. The cleaning method is to clean it with isopropanol first, and then use deionized water to rinse the residual liquid on the surface. Blow dry with a nitrogen gun.

[0035] (2) Uniformly spin-coat the polyurethane dispersion on the silicon wafer, heat and solidify to form the polyurethane elastic film 102, wherein the polyurethane dispersion is an anionic water-based aliphatic polyurethane dispersion with a solid content greater than 35%.

[0036] (3) The microfluidic structure 101 and the polyurethane elastic film 102 processed in steps (1) and (2) are subjected to plasma treatment, wherein the plasma treatment method is to put the microfluidic structure 101 and the polyurethane elastic film 102 into Oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com