Low-VOC high-strength high-toughness nylon and preparation method thereof

A high-strength, high-toughness, nylon technology, applied in the production of bulk chemicals, etc., can solve the problems of mechanical properties decline, VOC emission reduction, and improvement, etc., to achieve the effect of low cost, obvious toughening effect, and low VOC content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

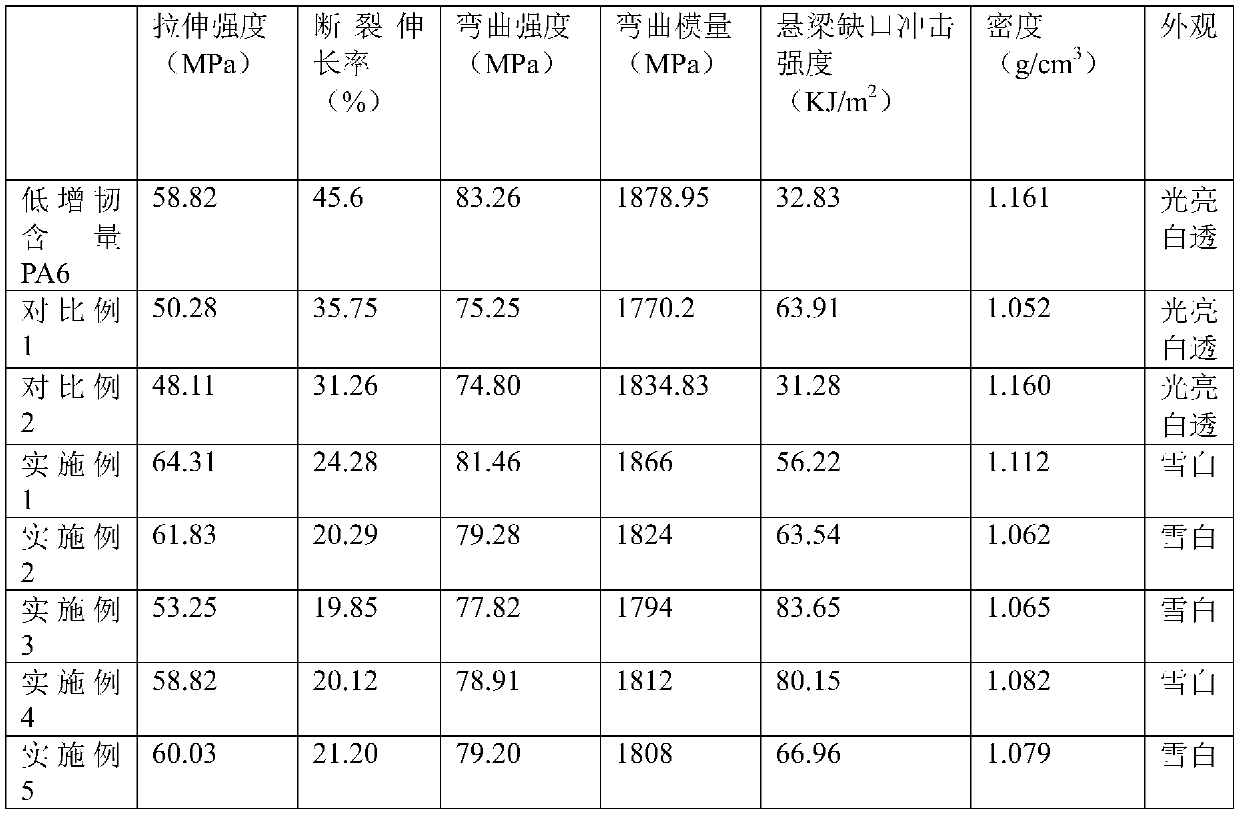

Examples

Embodiment 1

[0031] Weigh the following components in parts by weight: 95 parts of PA6 (Japan Ube, 1013B), 5 parts of toughening agent POE-g-MAH (Ningbo Nengzhiguang New Material Technology Co., Ltd. brand 413A), antioxidant (BASF b225) 0.3 parts, blend the above ingredients in a mixer for 20 minutes, add them to the twin-screw extruder, and set the temperature from zone 1 to zone 12 of the extruder to 150°C, 180°C, 200°C, 220°C, 230°C, 230°C , 235°C, 235°C, 235°C, 235°C, 230°C, 230°C, the machine head is 230°C, the mixed material is melted and plasticized, kneaded and mixed, extruded, cooled, pelletized, and dried to obtain primary products.

[0032] Put the primary product into the autoclave, control the temperature of the autoclave to 190°C, the volume of the primary product accounts for 3 / 2 of the volume of the autoclave, the pressure of the carbon dioxide injected into the autoclave is 12MPa, constant temperature and pressure for 40 minutes, and then 10MPa / The speed of s is depressur...

Embodiment 2

[0034]Weigh the following components in parts by weight: 95 parts of PA6 (Japan Ube, 1013B), 5 parts of toughening agent POE-g-MAH (Ningbo Nengzhiguang New Material Technology Co., Ltd. brand 413A), antioxidant (BASF b225) 0.3 parts, blend the above ingredients in a mixer for 20 minutes, add them to the twin-screw extruder, and set the temperature from zone 1 to zone 12 of the extruder to 150°C, 180°C, 200°C, 220°C, 230°C, 230°C , 235°C, 235°C, 235°C, 235°C, 230°C, 230°C, the machine head is 230°C, the mixed material is melted and plasticized, kneaded and mixed, extruded, cooled, pelletized, and dried to obtain primary products.

[0035] Put the primary product into the autoclave, control the temperature of the autoclave to 200°C, the volume of the primary product accounts for 3 / 2 of the volume of the autoclave, and the pressure of the carbon dioxide injected into the autoclave is 12MPa, constant temperature and pressure for 40 minutes, and then 10MPa The speed of / s is decomp...

Embodiment 3

[0037] Weigh the following components in parts by weight: 95 parts of PA6 (Japan Ube, 1013B), 5 parts of toughening agent POE-g-MAH (Ningbo Nengzhiguang New Material Technology Co., Ltd. brand 413A), antioxidant (BASF b225) 0.3 parts, blend the above ingredients in a mixer for 20 minutes, add them to the twin-screw extruder, and set the temperature from zone 1 to zone 12 of the extruder to 150°C, 180°C, 200°C, 220°C, 230°C, 230°C , 235°C, 235°C, 235°C, 235°C, 230°C, 230°C, the machine head is 230°C, the mixed material is melted and plasticized, kneaded and mixed, extruded, cooled, pelletized, and dried to obtain primary products.

[0038] Inject the primary product to get the product, then put the product into the autoclave, control the temperature of the autoclave to 200°C, the volume of the matrix product accounts for 3 / 2 of the volume of the autoclave, the pressure of carbon dioxide injected into the autoclave is 12MPa, and the constant temperature and pressure are 60 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com