A micro-current whitening mask with acoustic wave response characteristics and preparation method thereof

A response characteristic, whitening mask technology, applied in electrotherapy, skin care preparations, pharmaceutical formulations, etc., can solve the problems of insufficient weight, unattractive appearance of the mask, and limited power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

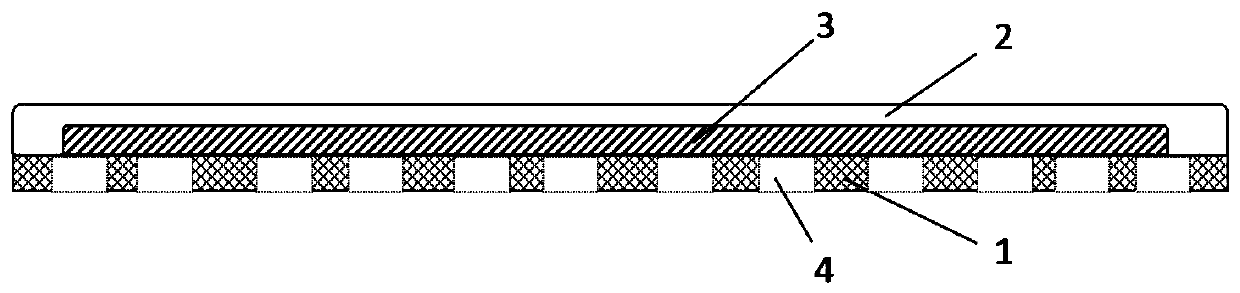

[0050] A method for preparing a micro-current whitening mask with acoustic response characteristics, the steps are as follows:

[0051] (1) Preparation of vibrating base film;

[0052] The vibrating base film is produced by electrospinning. The process parameters of electrospinning are: spinning solution concentration 7wt%, electrostatic voltage 34kV, spinning solution flow rate 6mL / h, receiving distance 17cm, drum speed 130rpm, spinneret diameter 0.7 mm, the solvent in the spinning solution is a mixture of DMF and THF with a volume ratio of 60:40;

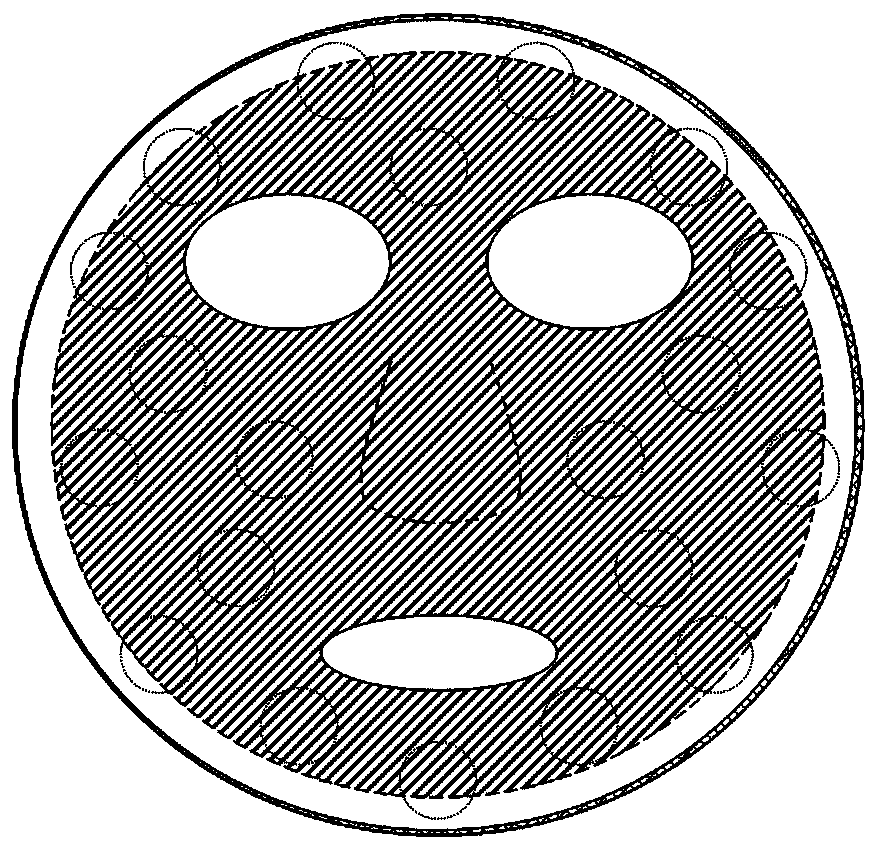

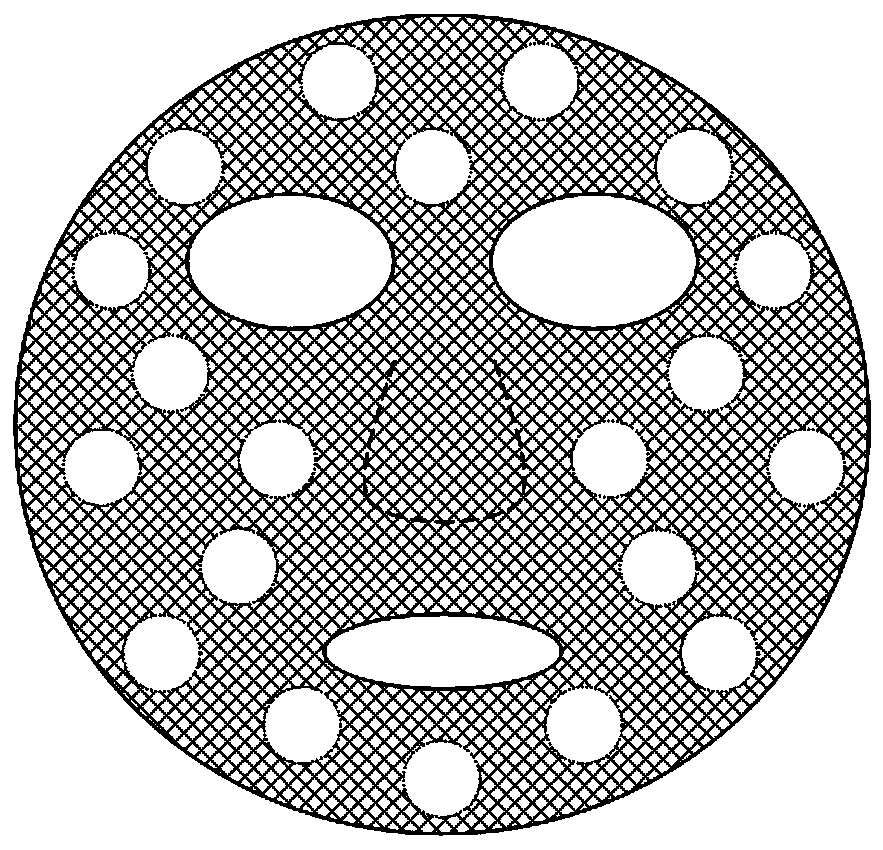

[0053] The prepared vibrating base film is PU / PANI nanofiber film, the content of PU in PU / PANI nanofiber film is 77.5% by weight; the thickness of the vibrating base film is 400μm and the surface area is 380cm 2 , The porosity is 80%, the diameter of the nanofibers in the vibrating base film is 366.67nm; the vibrating base film is provided with multiple through holes, the through holes are cylindrical holes, and the distance between two...

Embodiment 2

[0060] A method for preparing a micro-current whitening mask with acoustic response characteristics, the steps are as follows:

[0061] (1) Preparation of vibrating base film;

[0062] The vibrating base film is produced by electrospinning. The process parameters of electrospinning are: spinning solution concentration 7wt%, electrostatic voltage 36kV, spinning solution flow rate 5mL / h, receiving distance 14cm, drum speed 120rpm, spinneret diameter 0.9 mm, the solvent in the spinning solution is a mixture of DMF and THF with a volume ratio of 60:40;

[0063] The prepared vibrating base film is PU / PANI nanofiber film, the content of PU in PU / PANI nanofiber film is 77.5% by weight; the thickness of the vibrating base film is 400μm, and the surface area is 380cm 2 , The porosity is 80%, the diameter of the nanofibers in the vibrating base film is 366.67nm; there are multiple through holes on the vibrating base film, the through holes are cylindrical holes, the distance between two adjace...

Embodiment 3

[0070] A method for preparing a micro-current whitening mask with acoustic response characteristics, the steps are as follows:

[0071] (1) Preparation of vibrating base film;

[0072] The vibrating base film is prepared by electrospinning. The electrospinning process parameters are: spinning solution concentration 8wt%, electrostatic voltage 34kV, spinning solution flow rate 5mL / h, receiving distance 13cm, drum speed 150rpm, spinneret diameter 0.85 mm, the solvent in the spinning solution is a mixture of DMF and THF with a volume ratio of 60:40;

[0073] The prepared vibrating base film is PU / PANI nanofiber film, the content of PU in PU / PANI nanofiber film is 77.5% by weight; the thickness of the vibrating base film is 400μm, and the surface area is 380cm 2 , The porosity is 80%, the diameter of the nanofibers in the vibrating base film is 366.67nm; there are multiple through holes on the vibrating base film, the through holes are cylindrical holes, the distance between two adjacent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com