Sewage purifying photolysis water hydrogen generation double-function environment-friendly carbon nitride photocatalyst and preparation method and application thereof

An environmentally friendly technology for hydrogen production by photolysis of water, which is applied in the direction of light water/sewage treatment, hydrogen production, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

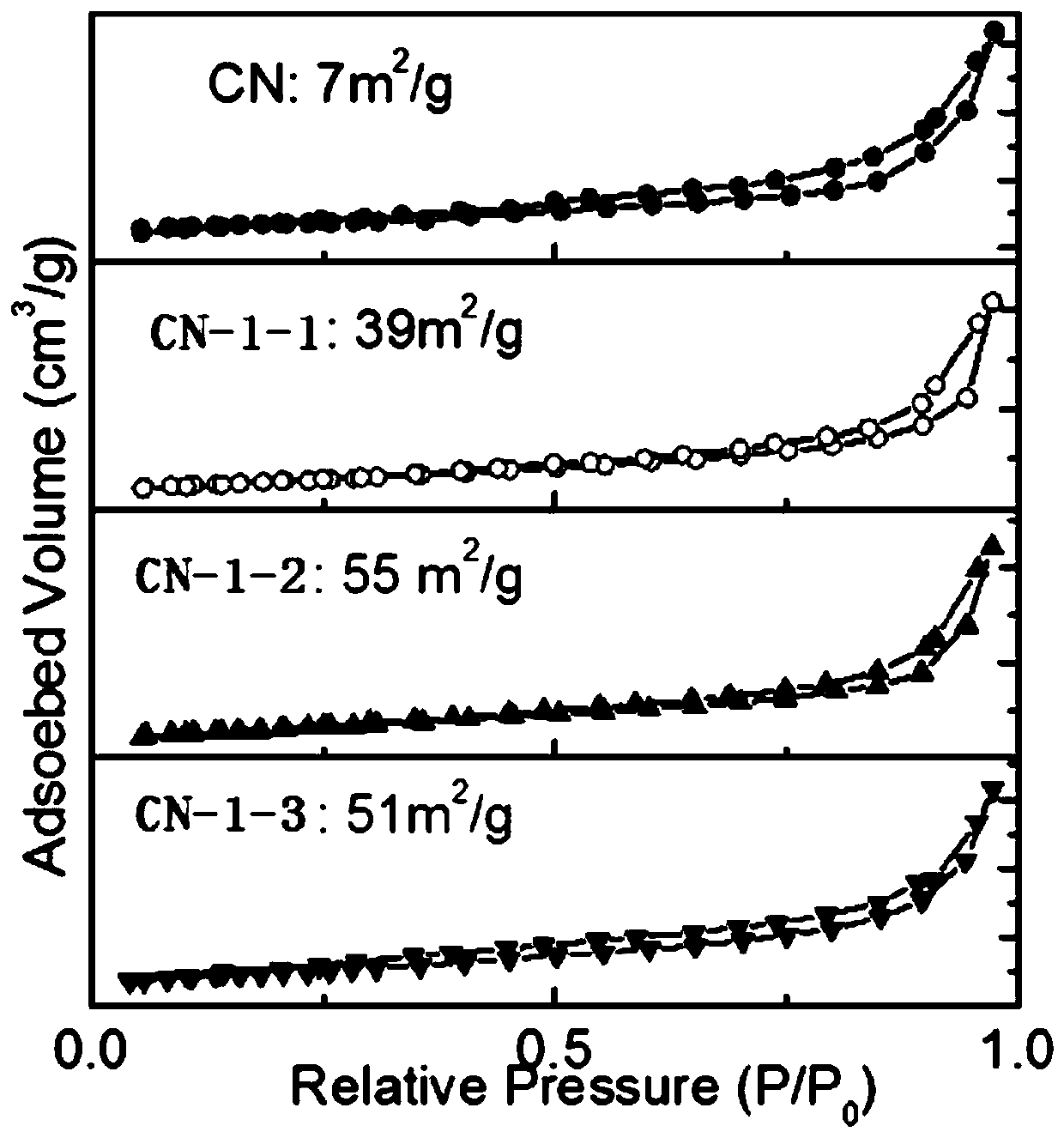

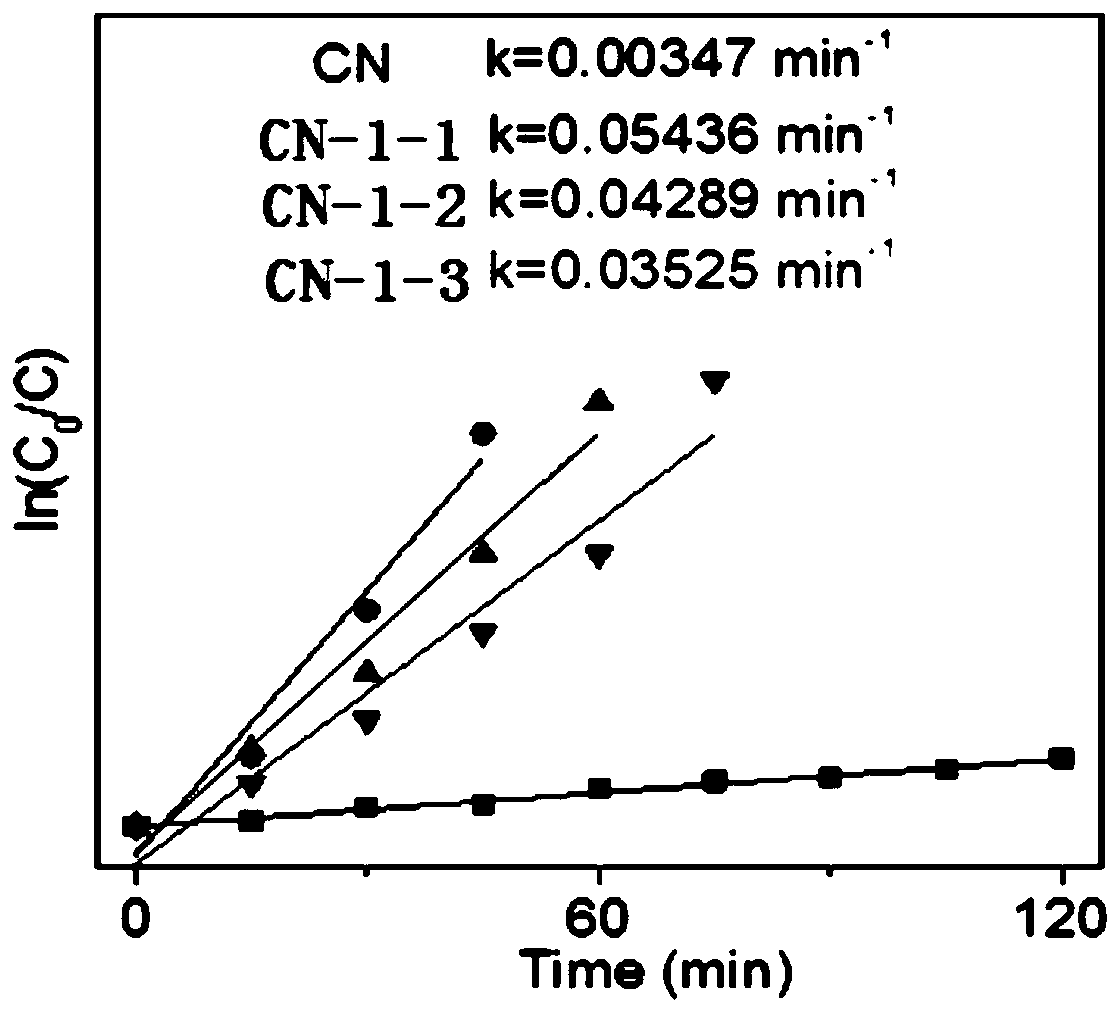

Embodiment 1

[0046] (1) Mixing of precursor and templating agent

[0047] Mix 1g of dicyandiamide and 1g of MgO in a certain ratio of 1:1, then grind and mix evenly.

[0048] (2) The first high-temperature roasting of the mixture

[0049] Transfer the well-mixed mixture to a crucible, put it into a tube furnace, and put it under nitrogen (N 2) conditions, first, pass nitrogen at room temperature for half an hour, remove the air in the tube, then raise the temperature from room temperature to 400 °C at a rate of 5 °C / min, then keep the temperature for 2 hours, then cool down to room temperature naturally, and remove it for use.

[0050] (3) Removal of templating agent

[0051] Grind the mixture after the first high-temperature roasting evenly, then add excess dilute acid solution, stir for 20 hours, and remove the template. Then, it was centrifugally washed with distilled water until the supernatant was neutral, and finally washed with ethanol, put into an oven, and dried at 80°C.

[00...

Embodiment 2

[0057] (1) Mixing of precursor and templating agent

[0058] Mix 1g of dicyandiamide and 2g of MgO in a certain ratio of 1:2, then grind and mix evenly.

[0059] (2) The first high-temperature roasting of the mixture

[0060] Transfer the well-mixed mixture to a crucible, put it into a tube furnace, and put it under nitrogen (N 2 ) conditions, first, pass nitrogen at room temperature for half an hour, remove the air in the tube, then raise the temperature from room temperature to 400 °C at a rate of 5 °C / min, then keep the temperature for 2 hours, then cool down to room temperature naturally, and remove it for use.

[0061] (3) Removal of templating agent

[0062] Grind the mixture after the first high-temperature roasting evenly, then add excess dilute acid solution, stir overnight, and remove the template. Then, it was centrifugally washed with distilled water until the supernatant was neutral, and finally washed with ethanol, put into an oven, and dried at 80°C.

[0063...

Embodiment 3

[0068] (1) Mixing of precursor and templating agent

[0069] Mix 1g of dicyandiamide and 4g of MgO in a certain ratio of 1:4, then grind and mix evenly.

[0070] (2) The first high-temperature roasting of the mixture

[0071] Transfer the well-mixed mixture to a crucible, put it into a tube furnace, and put it under nitrogen (N 2 ) conditions, first, pass nitrogen at room temperature for half an hour, remove the air in the tube, then raise the temperature from room temperature to 400 °C at a rate of 5 °C / min, then keep the temperature for 2 hours, then cool down to room temperature naturally, and remove it for use.

[0072] (3) Removal of templating agent

[0073] Grind the mixture after the first high-temperature roasting evenly, then add excess dilute acid solution, stir overnight, and remove the template. Then, it was centrifugally washed with distilled water until the supernatant was neutral, and finally washed with ethanol, put into an oven, and dried at 80°C.

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com