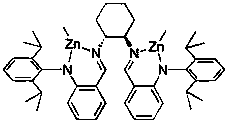

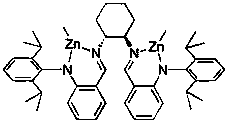

Dual-nucleus chiral amine-imine magnesium complex and preparation method and application thereof

A technology of amine imide magnesium and complexes, which is applied in the direction of magnesium organic compounds, can solve problems such as metal residues, and achieve the effects of low cost, high product yield, and controllable molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

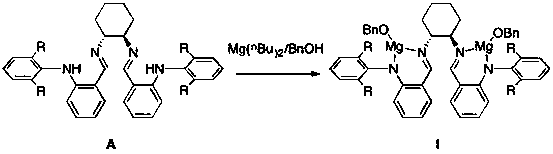

Embodiment 1

[0038]The structural formula of the ligand used is the above formula (A), where R is hydrogen, and the reaction process is as follows: under a nitrogen atmosphere, slowly add 5 mL of benzyl alcohol tetrahydrofuran solution (2.0 mol / L) to an equimolar amount of Mg( n Bu) 2 Hexane solution (2.0 mol / L, 5 mL) was reacted for 1 hour, 2.14 g of the ligand was dissolved in 25 mL of dry toluene, and added to Mg( n Bu) 2 In the reaction mixture with benzyl alcohol, after adding, the reaction liquid was naturally raised to room temperature, and then heated to 60 ° C for 3 hours. After the reaction was completed, the solvent was vacuum-dried, and the residue was washed with dry n-hexane, filtered, and then the product was collected and dried. Weighed to obtain 3.05 g of solid, the yield was 83.4%.

Embodiment 2

[0040] The structural formula of the ligand used is the above formula (A), where R is a methyl group, and the reaction process is as follows: under a nitrogen atmosphere, slowly add 5 mL of benzyl alcohol tetrahydrofuran solution (2.0 mol / L) to an equimolar amount of Mg( n Bu) 2 Hexane solution (2.0 mol / L, 5 mL) was reacted for 1 hour, 2.64 g of the ligand was dissolved in 25 mL of dry toluene, and added to Mg( n Bu) 2 and benzyl alcohol reaction mixture, after adding, the reaction liquid was naturally raised to room temperature, and then heated to 40 ° C for 10 hours, after the reaction was completed, the solvent was vacuum-dried, and the residue was washed with dry n-hexane, filtered, and then the product was collected and dried Weighed to obtain 3.33 g of solid, the yield was 84.5%.

Embodiment 3

[0042] The structural formula of the ligand used is the above formula (A), where R is ethyl, and the reaction process is as follows: under a nitrogen atmosphere, slowly add 5 mL of benzyl alcohol tetrahydrofuran solution (2.0 mol / L) to an equimolar amount of Mg( n Bu) 2 Hexane solution (2.0 mol / L, 5 mL) was reacted for 1 hour, 2.92 g of the ligand was dissolved in 30 mL of dry toluene, and added to Mg( n Bu) 2 In the reaction mixture with benzyl alcohol, after the addition, the reaction liquid was naturally raised to room temperature, and then heated to 50°C for 6 hours. After the reaction was completed, the solvent was vacuum-dried, and the residue was added to dry n-hexane to filter and washed with dry n-hexane. , the product was collected and dried and weighed to obtain 3.66 g of solid, with a yield of 86.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com