Special halogen-free flame-retardant recycled PET (polyethylene terephthalate) sheet material for coil packaging and preparation method thereof

A technology for packaging and special materials, applied in the field of packaging material manufacturing, can solve the problems of poor impact resistance, low tensile strength and high price, and achieve the effects of good mechanical properties, low melt viscosity and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

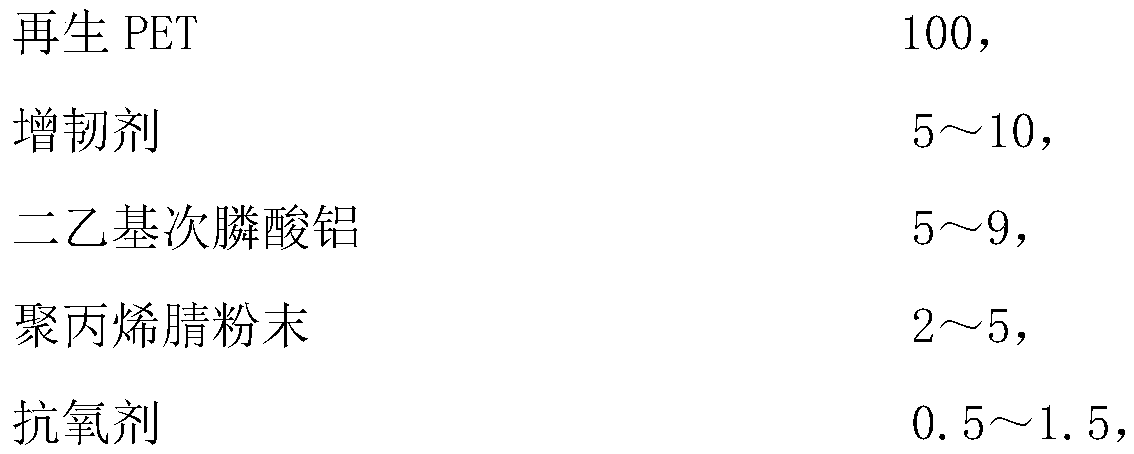

[0019] A special halogen-free flame-retardant high-impact recycled PET sheet material for steel coil packaging, which is prepared from recycled PET, toughening agent, aluminum diethylphosphinate, polyacrylonitrile powder, and antioxidant raw materials. The parts by weight of each raw material are:

[0020]

[0021] The intrinsic viscosity value of described recycled PET is 0.55dl / g,

[0022] The toughening agent is ethylene-methyl acrylate-glycidyl methacrylate random terpolymer,

[0023] The antioxidant is selected from tris[2,4-di-tert-butylphenyl]phosphite.

[0024] The polyacrylonitrile powder is homopolyacrylonitrile, with an average particle diameter of 25um and a weight average molecular weight of M w for 25000.

[0025] The preparation method of the halogen-free flame-retardant recycled PET sheet special material for steel coil packaging in this embodiment comprises the following process steps:

[0026] 1) Dry the recycled PET in an oven for later use: the dryin...

Embodiment 2

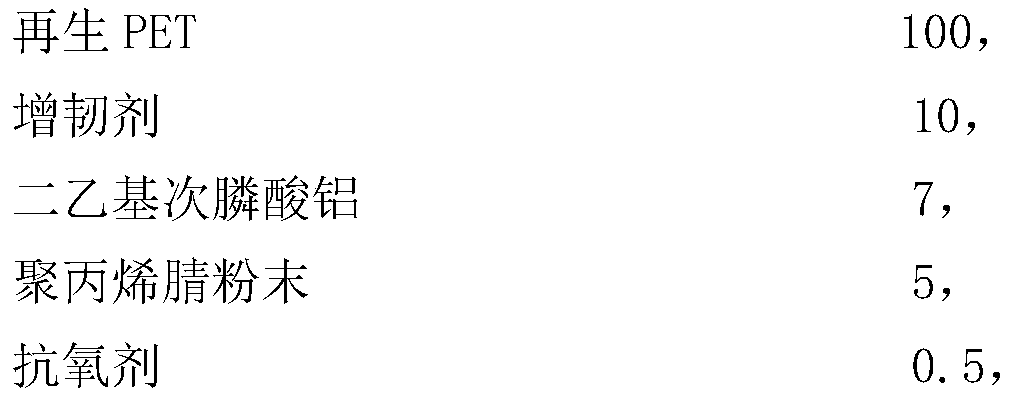

[0032] A special halogen-free flame-retardant recycled PET sheet material for steel coil packaging, which is prepared from recycled PET, toughening agent, aluminum diethylphosphinate, polyacrylonitrile powder, and antioxidant raw materials. The parts by weight are:

[0033]

[0034] The intrinsic viscosity value of the regenerated PET is 0.60dl / g,

[0035] The toughening agent is ethylene-methyl acrylate-glycidyl methacrylate random terpolymer,

[0036] The antioxidant is selected from three [2,4-di-tert-butylphenyl] phosphite,

[0037] The polyacrylonitrile powder is homopolyacrylonitrile, with an average particle diameter of 30um and a weight average molecular weight of M w is 25000,

[0038] The preparation method of the halogen-free flame-retardant recycled PET sheet special material for steel coil packaging includes the following process steps:

[0039] 1) Dry the recycled PET in an oven for later use: the drying temperature is 120°C, and the drying time is 4 hours...

Embodiment 3

[0045] A special halogen-free flame-retardant recycled PET sheet material for steel coil packaging, which is prepared from recycled PET, toughening agent, aluminum diethylphosphinate, polyacrylonitrile powder, and antioxidant raw materials. The parts by weight are:

[0046]

[0047] The intrinsic viscosity value of described recycled PET is 0.65dl / g,

[0048] The toughening agent is ethylene-methyl acrylate-glycidyl methacrylate random terpolymer,

[0049] Described antioxidant is selected from two (2,4-di-tert-butylphenyl) pentaerythritol diphosphates,

[0050] The polyacrylonitrile powder is homopolyacrylonitrile, with an average particle diameter of 30um and a weight average molecular weight of M w for 25000.

[0051] The preparation method of the halogen-free flame-retardant recycled PET sheet special material for steel coil packaging in this embodiment comprises the following process steps:

[0052] 1) Dry the recycled PET in an oven for later use: the drying tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com