A Circulation System of Gas Injection Enthalpy Increase Heat Pump Using Non-azeotropic Mixture with Subcooler

A circulation system and gas injection technology for increasing enthalpy, applied in the field of heat pumps, can solve the problems of failure to make full use of the phase change temperature glide characteristics of non-azeotropic mixture refrigerants, the decrease of the cycle performance coefficient of the heating efficiency of the cycle system, and the insufficient cycle efficiency of heat pumps, etc. , to achieve the effects of simple structure, increased evaporation pressure, and improved heating coefficient of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

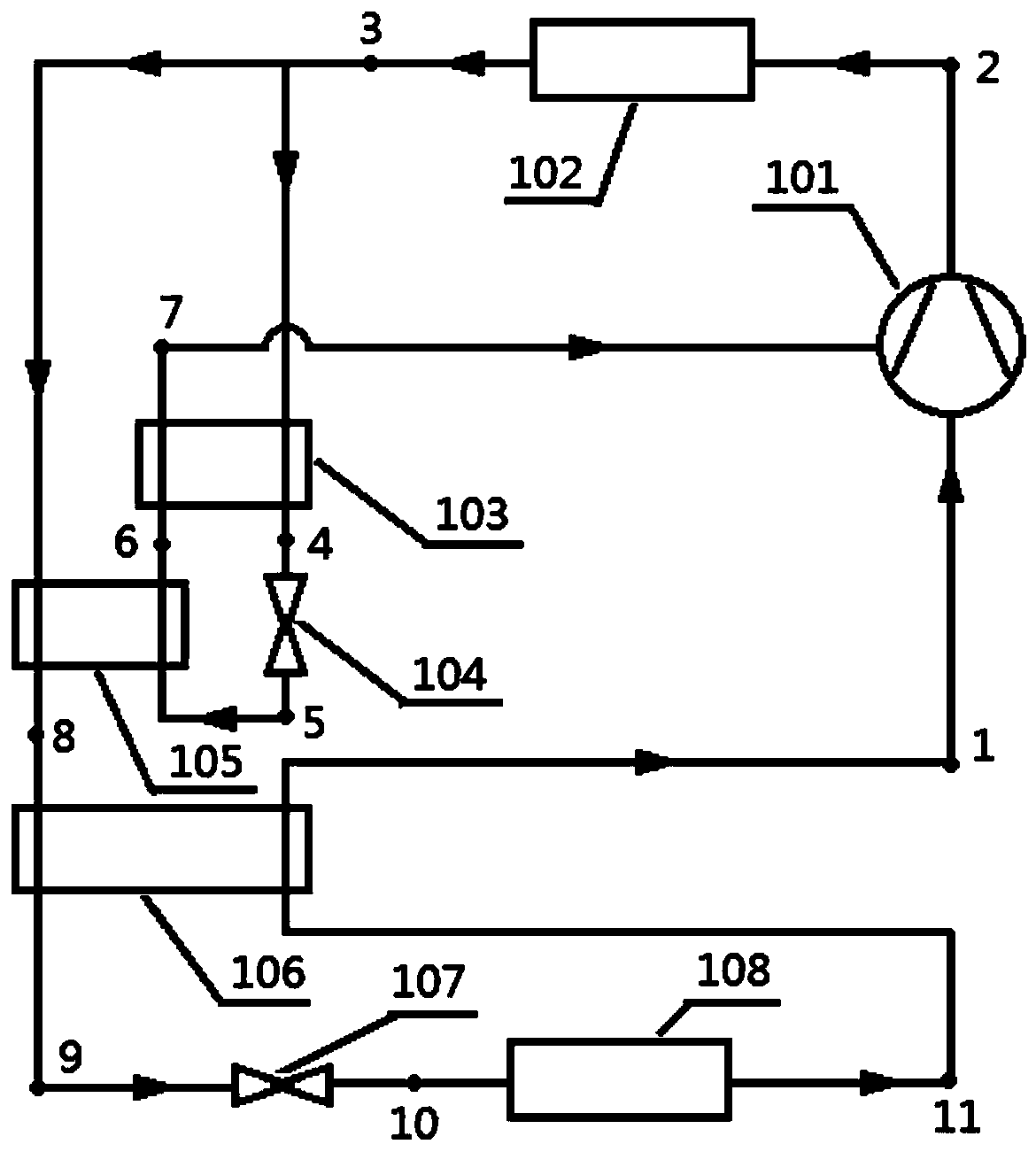

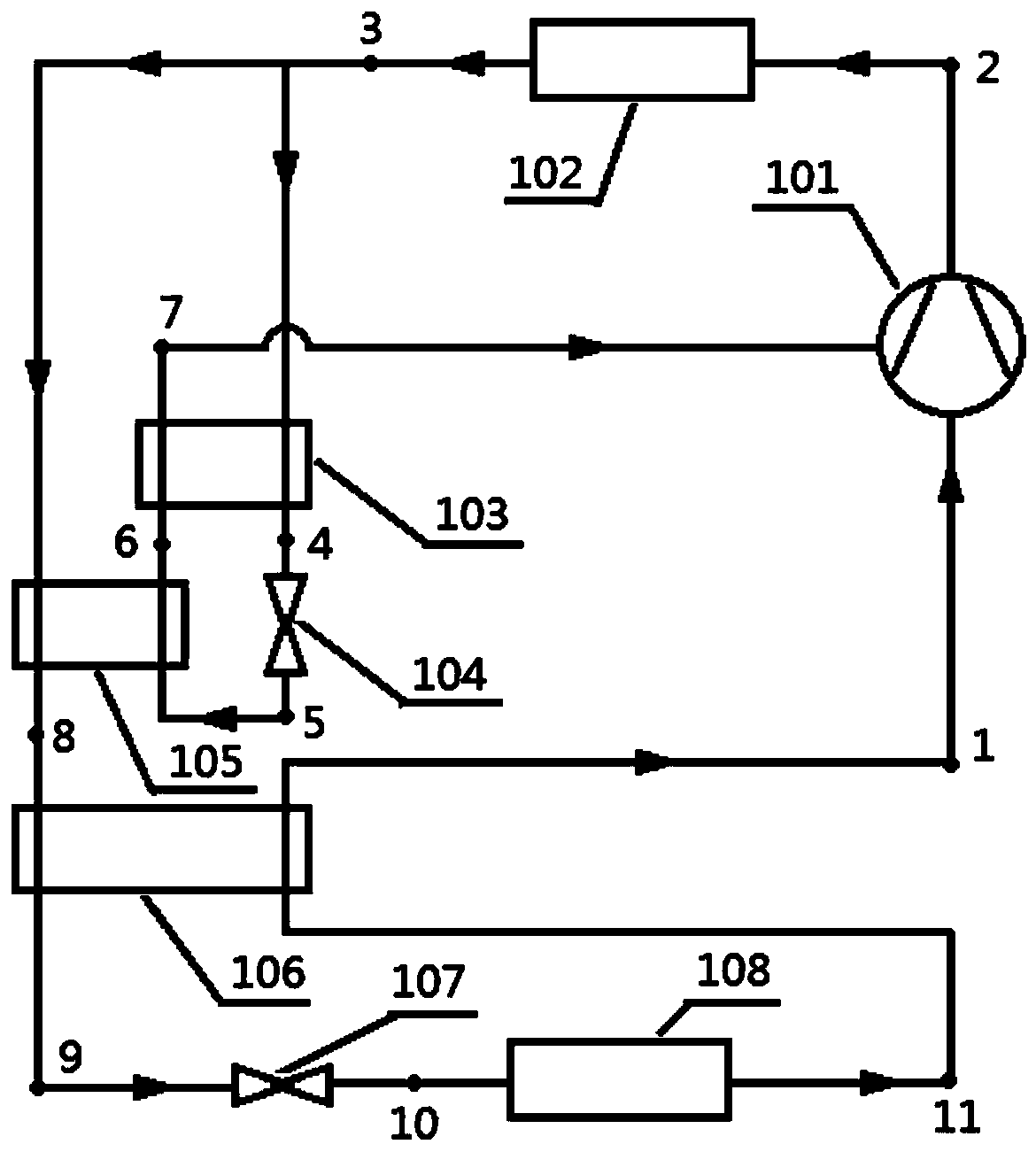

[0012] like figure 1 As shown, the present invention is a zeotropic mixture band subcooler gas injection enthalpy-increasing heat pump cycle system for heat pump devices, including a compressor 101, the outlet of the compressor 101 is connected to the inlet of the condenser 102; the condenser 102 liquid The outlet is divided into two paths: one path is connected to the inlet of the second subcooler 105 through the first subcooler 103 and the first expansion valve 104, and then connected to the middle gas injection port of the compressor 101 through the first subcooler 103; One path is connected to the inlet of the second expansion valve 107 through the second subcooler 105 and the third subcooler 106, the outlet of the second expansion valve 107 is connected to the inlet of the evaporator 108, and the outlet of the evaporator 108 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com