Method for preparing high-performance silicon-carbon negative electrode composite material of lithium ion battery

A technology of lithium-ion batteries and composite materials, which is applied in the field of preparation of silicon-carbon negative electrode composite materials, can solve the problems of not meeting the needs of industrialization, complicated preparation process, uncontrollable, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

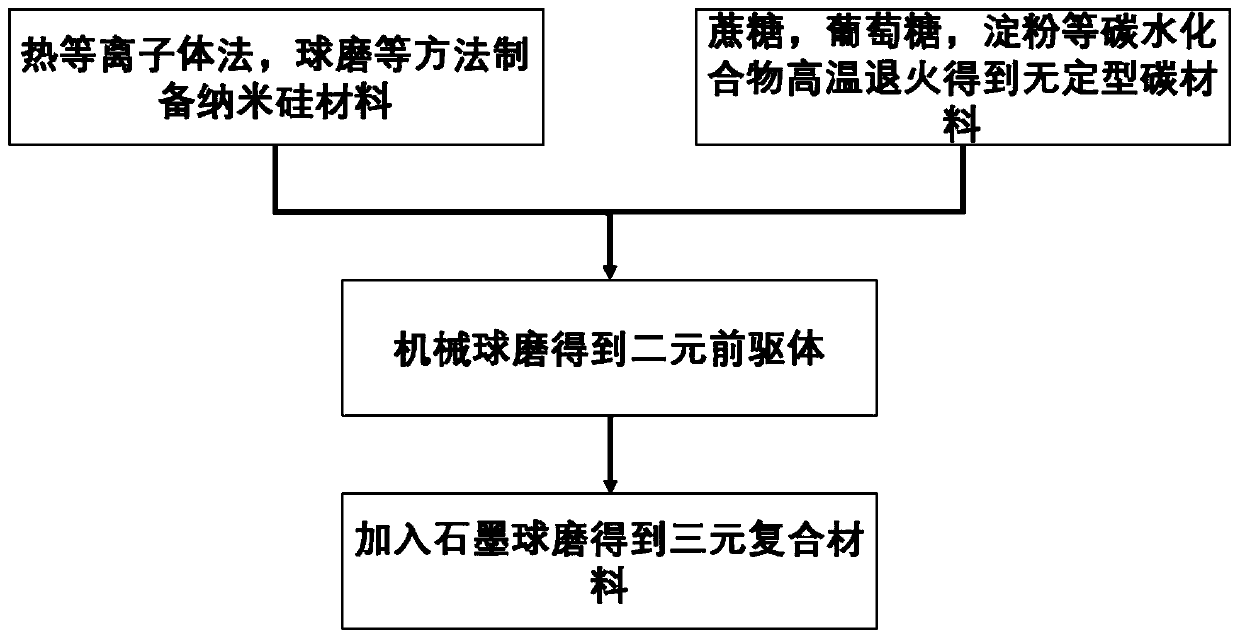

Method used

Image

Examples

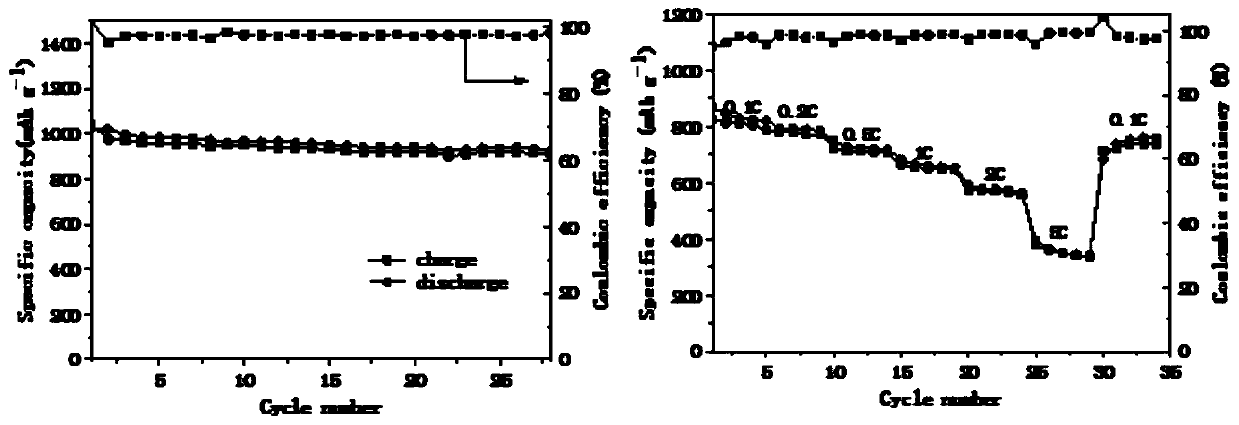

Embodiment 1

[0037] First, a high-quality nano-silicon is prepared by thermal plasma method. 2kg of silicon powder with a particle size of 25μm is gradually fed into the powder feeder, and then the working gas argon is passed into the plasma reaction equipment as a carrier. The flow rate of the gas is 0.5m 3 h -1 , the flow rate of argon as side gas is 5.0m 3 h -1 , the flow rate of the central gas argon is 68m 3 h -1 . Turn on the powder feeder, output the silicon powder at a speed of 2g / min, and transport it to the high temperature zone sent to the reaction center through the carrier gas (argon gas), waiting for the silicon powder to be vaporized or decomposed into gas. Then its gaseous state is sent to the low temperature zone through the central gas (argon gas), at 10m 3 / h Rapid cooling, gaseous atoms nucleate and grow at a suitable temperature to form high-quality nano-silicon spheres, which are collected for use.

[0038] Select 1kg of high-quality sucrose material and put it...

Embodiment 2

[0041] First, a high-quality nano-silicon is prepared by thermal plasma method. 2kg of silicon powder with a particle size of 25μm is gradually fed into the powder feeder, and then the working gas argon is passed into the plasma reaction equipment as a carrier. The flow rate of the gas is 0.5m 3 h -1 , the flow rate of argon as side gas is 5.0m 3 h -1 , the flow rate of the central gas argon is 68m 3 h -1 . Turn on the powder feeder, output the silicon powder at a speed of 2g / min, and transport it to the high temperature zone sent to the reaction center through the carrier gas (argon gas), waiting for the silicon powder to be vaporized or decomposed into gas. Then its gaseous state is sent to the low temperature zone through the central gas (argon gas), at 10m 3 / h Rapid cooling, gaseous atoms nucleate and grow at a suitable temperature to form high-quality nano-silicon spheres, which are collected for use.

[0042] Select 1kg of high-quality sucrose material and put it...

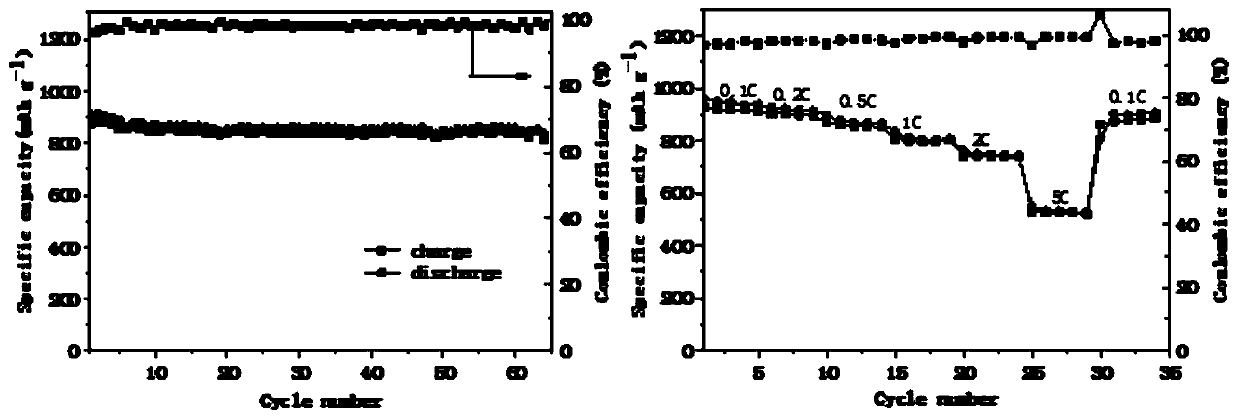

Embodiment 3

[0045] First, a high-quality nano-silicon is prepared by thermal plasma method. 2kg of silicon powder with a particle size of 25μm is gradually fed into the powder feeder, and then the working gas argon is passed into the plasma reaction equipment as a carrier. The flow rate of the gas is 0.5m 3 h -1 , the flow rate of argon as side gas is 5.0m 3 h -1 , the flow rate of the central gas argon is 68m 3 h -1 . Turn on the powder feeder, output the silicon powder at a speed of 2g / min, and transport it to the high temperature zone sent to the reaction center through the carrier gas (argon gas), waiting for the silicon powder to be vaporized or decomposed into gas. Then its gaseous state is sent to the low temperature zone through the central gas (argon gas), at 10m 3 / h Rapid cooling, gaseous atoms nucleate and grow at a suitable temperature to form high-quality nano-silicon spheres, which are collected for use.

[0046] Select 1kg of high-quality sucrose material and put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com