Preparation method of all-vanadium redox flow battery electrolyte

A liquid flow battery and electrolyte technology, applied in the direction of regenerative fuel cells, etc., can solve the problems of complex electrolyte production process, residual impurities, slow reaction rate, etc., and achieve low-cost clean production, low cost, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing an electrolyte solution for an all-vanadium redox flow battery. The preparation method described in this embodiment is:

[0028] Step 1. Mix vanadium pentoxide and deionized water according to a solid-to-liquid ratio of (100-150): 1g / L, mix the vanadium pentoxide and the deionized water, and stir to obtain a mixed slurry.

[0029] Step 2, according to the molar ratio of sulfuric acid: vanadium pentoxide (2-3): 1, adding the sulfuric acid into the mixed slurry and stirring to obtain an activated slurry.

[0030] Step 3, according to carbonaceous reductant: molar ratio of vanadium pentoxide is (0.5~1.5): 1, described carbonaceous reductant is added in described activation slurry, then adds all described carbonaceous reductant The activated slurry is placed in a reaction kettle, stirred at 100-160° C. for 1-2 hours, and filtered to obtain a crude electrolyte solution.

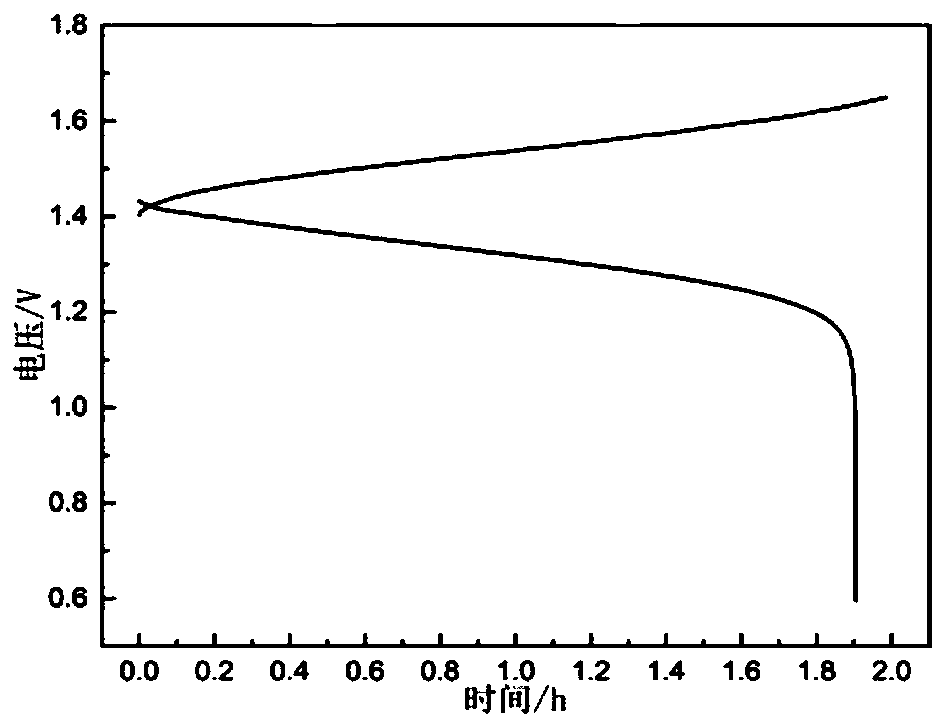

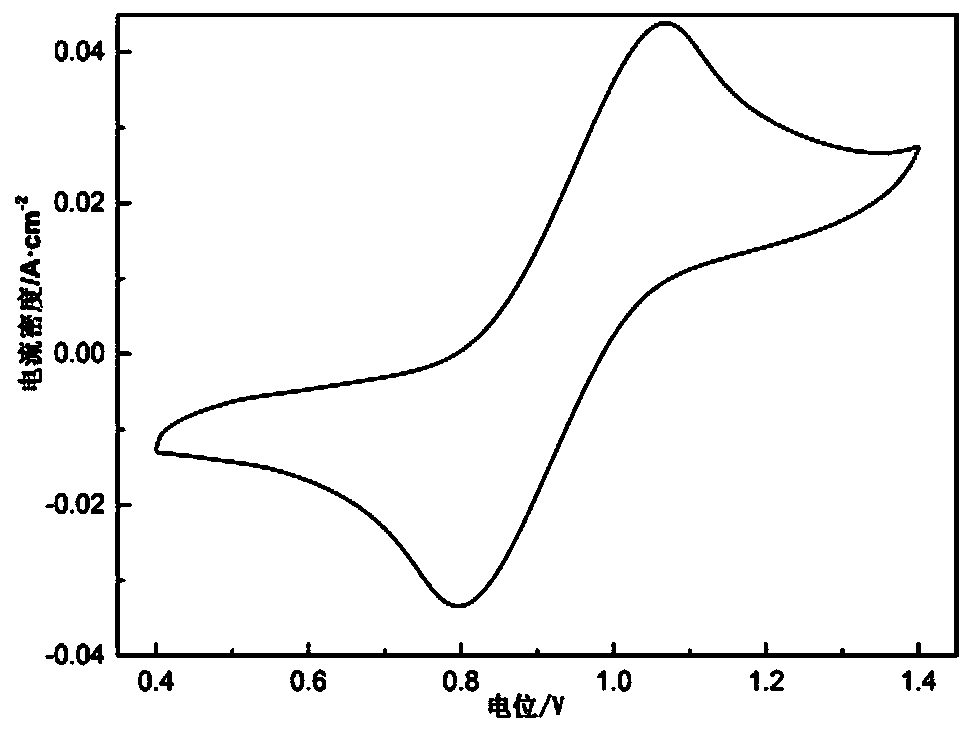

[0031] Step 4, placing the thick electrolyte solution on the negative electrode...

Embodiment 2

[0035] A method for preparing an electrolyte solution for an all-vanadium redox flow battery. The preparation method described in this embodiment is:

[0036] Step 1. Mix vanadium pentoxide and deionized water according to a solid-to-liquid ratio of (150-200): 1g / L, mix the vanadium pentoxide and the deionized water, and stir to obtain a mixed slurry.

[0037] Step 2. According to the molar ratio of sulfuric acid: vanadium pentoxide (3-4): 1, add the sulfuric acid into the mixed slurry and stir to obtain an activated slurry.

[0038] Step 3, according to carbonaceous reductant: molar ratio of vanadium pentoxide is (1.0~2.0): 1, described carbonaceous reductant is added in described activation slurry, then adds all described carbonaceous reductant The activated slurry is placed in a reaction kettle, stirred at 120-180° C. for 2-3 hours, and filtered to obtain a crude electrolyte solution.

[0039] Step 4, placing the thick electrolyte solution on the negative electrode of the...

Embodiment 3

[0043] A method for preparing an electrolyte solution for an all-vanadium redox flow battery. The preparation method described in this embodiment is:

[0044] Step 1. Mix vanadium pentoxide and deionized water according to a solid-to-liquid ratio of (200-250): 1 g / L, mix the vanadium pentoxide and the deionized water, and stir to obtain a mixed slurry.

[0045] Step 2: According to the molar ratio of sulfuric acid: vanadium pentoxide (4-5): 1, add the sulfuric acid into the mixed slurry and stir to obtain an activated slurry.

[0046] Step 3, according to carbonaceous reductant: the molar ratio of vanadium pentoxide is (1.5~2.5): 1, described carbonaceous reductant is added in the described activation slurry, then adds all described carbonaceous reductant The activated slurry is placed in a reaction kettle, stirred at 140-200° C. for 1-2 hours, and filtered to obtain a crude electrolyte solution.

[0047] Step 4, placing the thick electrolyte solution on the negative electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com