High-power column vector optical fiber laser

A technology of fiber lasers and column vectors, which is applied to lasers, laser parts, cladding fibers, etc., can solve the problems of poor stability and low output power, and achieve the effects of reduced coupling, simple and compact structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

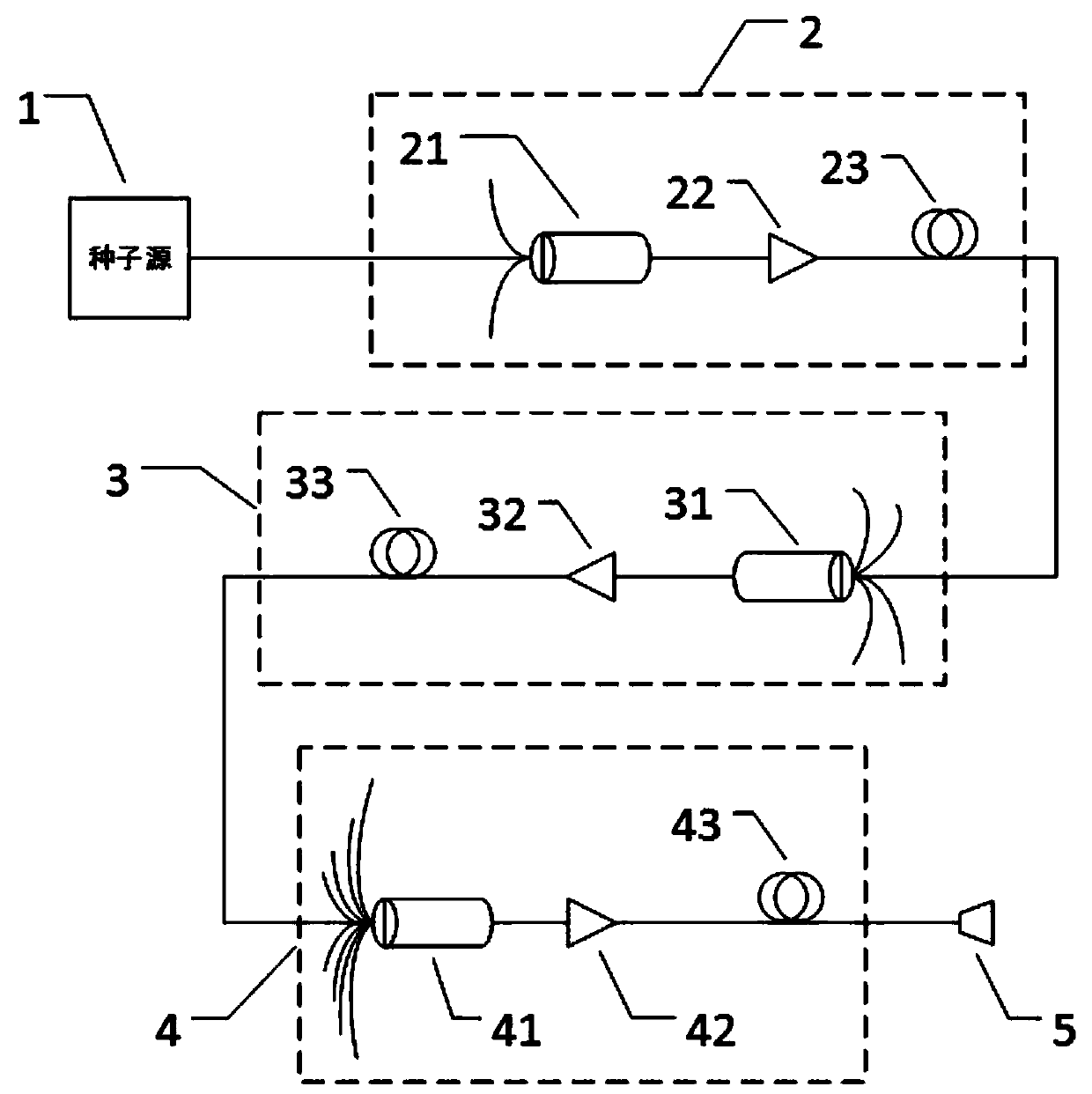

[0049] refer to figure 1 , is an application example of the present invention—high-power columnar vector CW fiber laser, the fiber laser 1 of single columnar vector mode output is the CW fiber laser of linear cavity single columnar vector mode output, refer to Figure 7 . In this laser, the pump source 201 adopts a semiconductor laser with a center wavelength of 975nm, and is connected to the pump end of the wavelength division multiplexer 202 through pigtail fusion, and the wavelength division multiplexer 202 adopts a 975nm / 1064nm wavelength division multiplexer. It is connected to the pigtail fiber of the input grating 203 by pigtail fusion. The input grating 203 adopts the grating engraved on the ring-core optical fiber, and its reflectivity to the LP11 mode of the 1064nm waveband is close to 100%, while for the pump light of the 975nm waveband completely transparent, and then connected to the gain fiber 204 by fusion splicing.

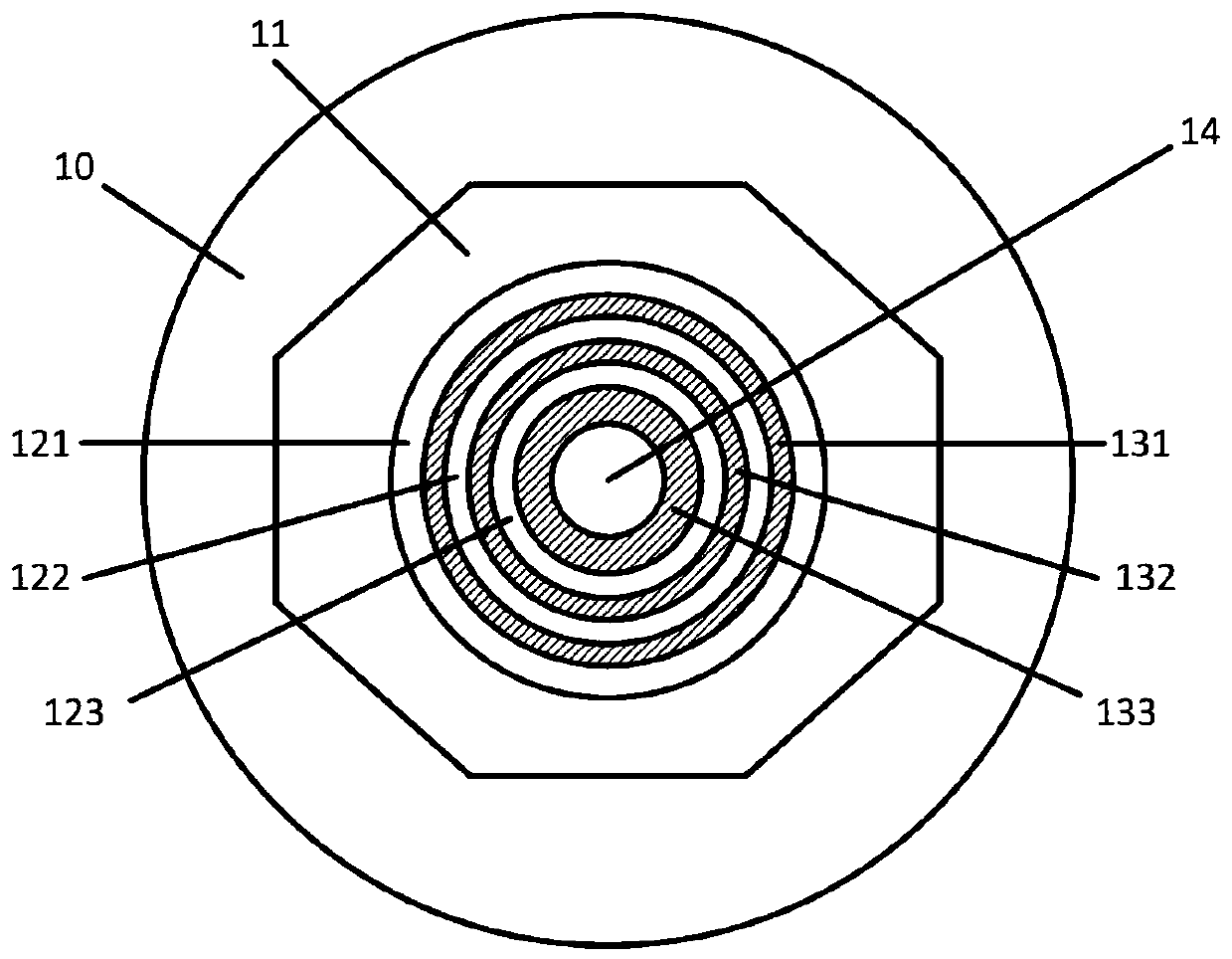

[0050] Ring core fiber structure reference...

Embodiment 2

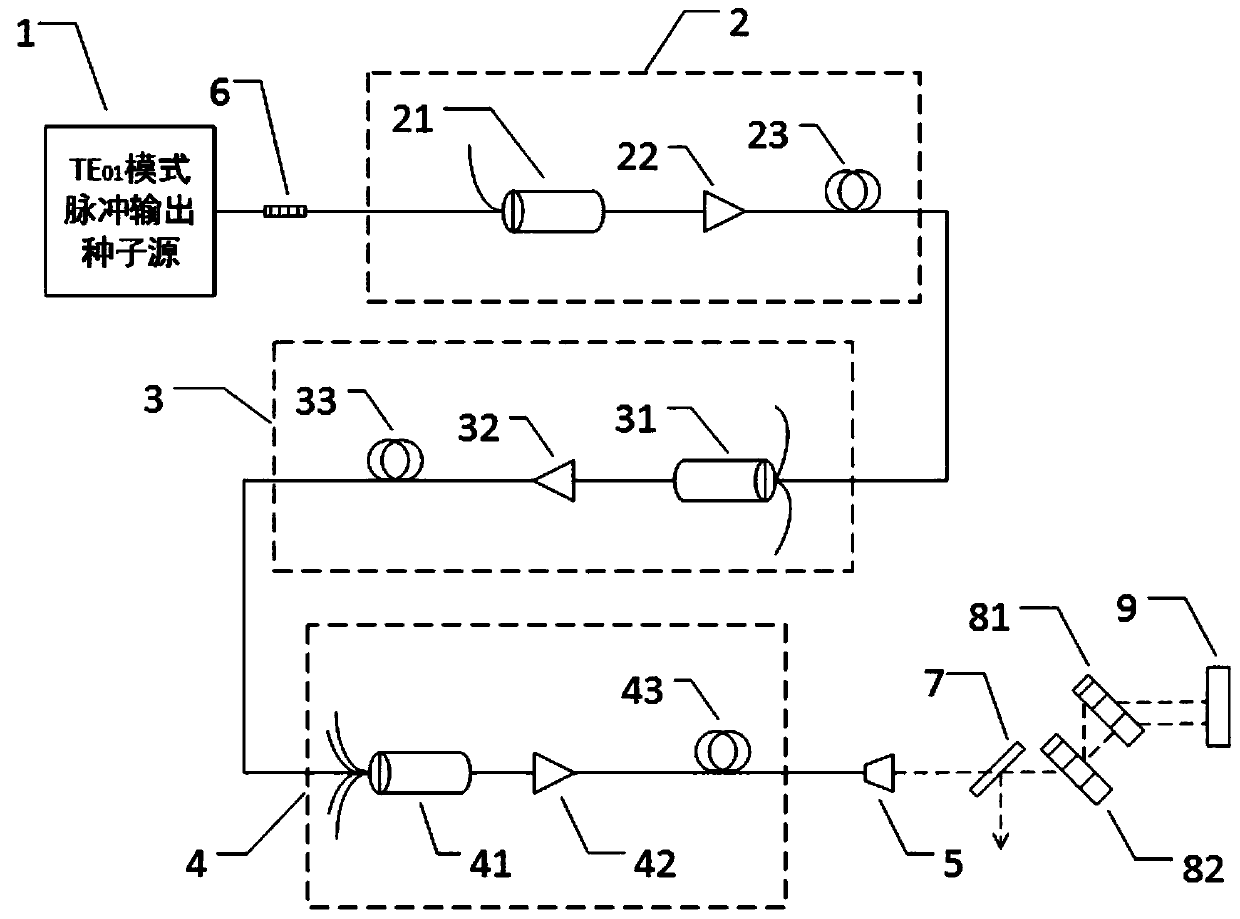

[0058] refer to figure 2 , is an application example of the present invention—high-power columnar vector pulsed fiber laser, and the fiber laser 1 with single columnar vector mode output is a pulsed fiber laser with linear cavity single columnar vector mode output, refer to Figure 8 , in this laser, the pump source 301 adopts a semiconductor laser with a center wavelength of 975nm, the wavelength division multiplexer 302 adopts a 975nm / 1064nm wavelength division multiplexer, and the pigtail of the pump source 301 is welded with the wavelength division multiplexer The pump end of device 302 is connected. The input grating 303 adopts the grating engraved on the ring-core optical fiber, and its reflectivity for the LP11 mode in the 1064nm band is close to 100%, while it completely transmits the pump light in the 975nm band.

[0059] Ring core fiber structure reference Figure 5 , the guided mode layer 16 is a ring-shaped distribution of germanium-doped silicon dioxide, and th...

Embodiment 3

[0069] refer to figure 2 , is an application example of the present invention—a high-power column vector pulsed fiber laser, and the fiber laser 1 with single column vector mode output is a pulsed fiber laser with ring cavity single column vector mode output. In this laser, the pump source 401 is a semiconductor laser with a center wavelength of 975nm, and the wavelength division mode division multiplexer 402 is made of HI1060 optical fiber and ring-core optical fiber fusion taper, which can realize multiplexing of 980nm / 1064nm wavelength, And the LP01 mode with a center wavelength of 980nm in the HI1060 fiber is coupled to the TE01 mode in the ring-core fiber. The pigtail of the pump source 401 is welded to the pigtail of the pump end of the wavelength division mode multiplexer 402 .

[0070] Ring core fiber structure reference Figure 5 , the guided mode layer 16 is a ring-shaped distribution of germanium-doped silicon dioxide, and the low-refractive index layer 17 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com