Propane dehydrogenation catalyst and preparation method thereof and method for preparing propylene by propane dehydrogenation

A propane dehydrogenation and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of easy deactivation, low propane conversion rate and low propylene selectivity , unstable mesoporous structure, etc., to achieve the effect of strong hydrophobicity, excellent hydrothermal stability, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

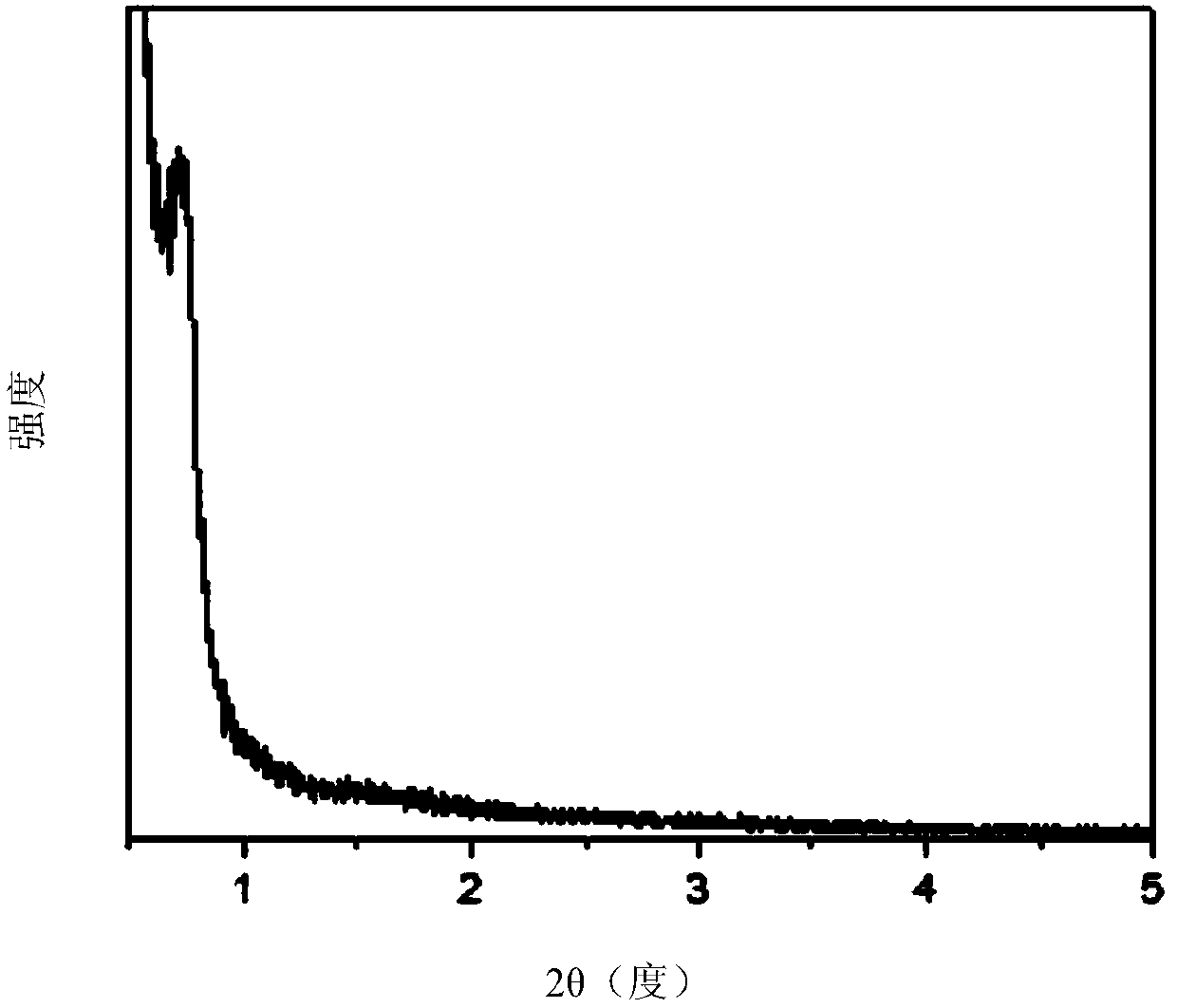

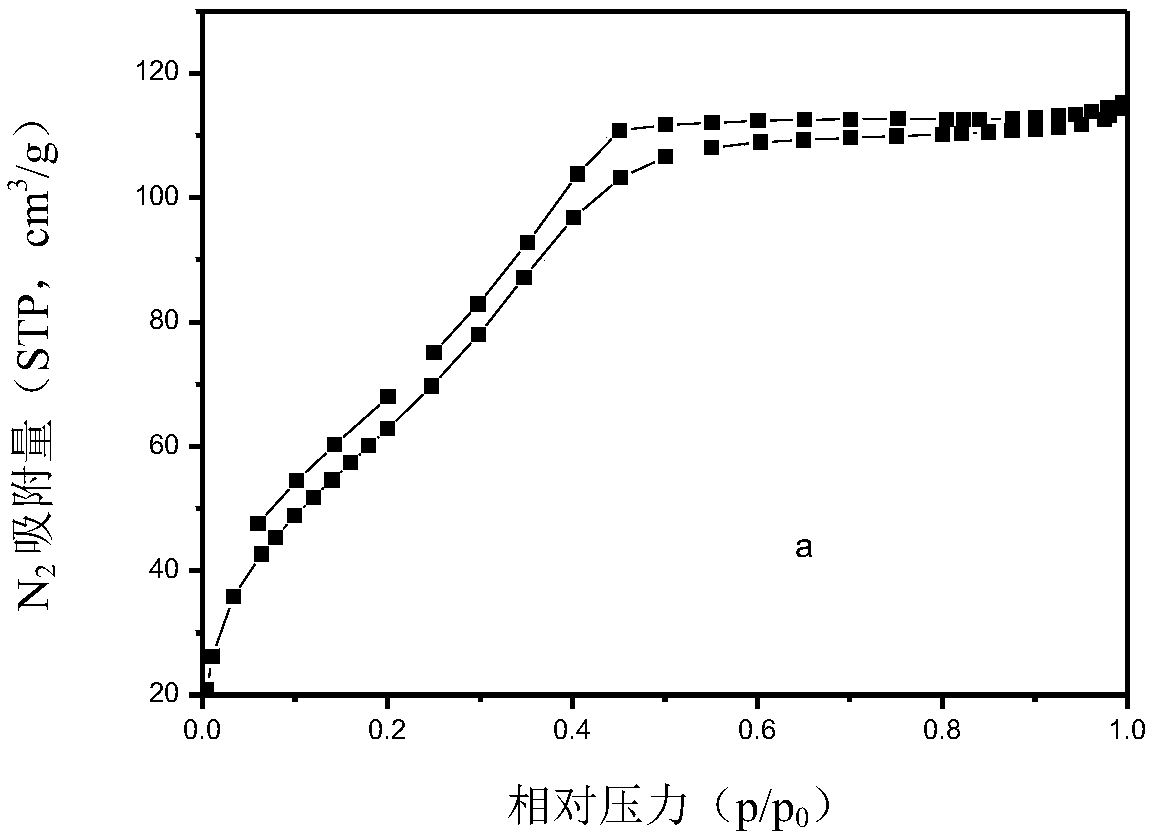

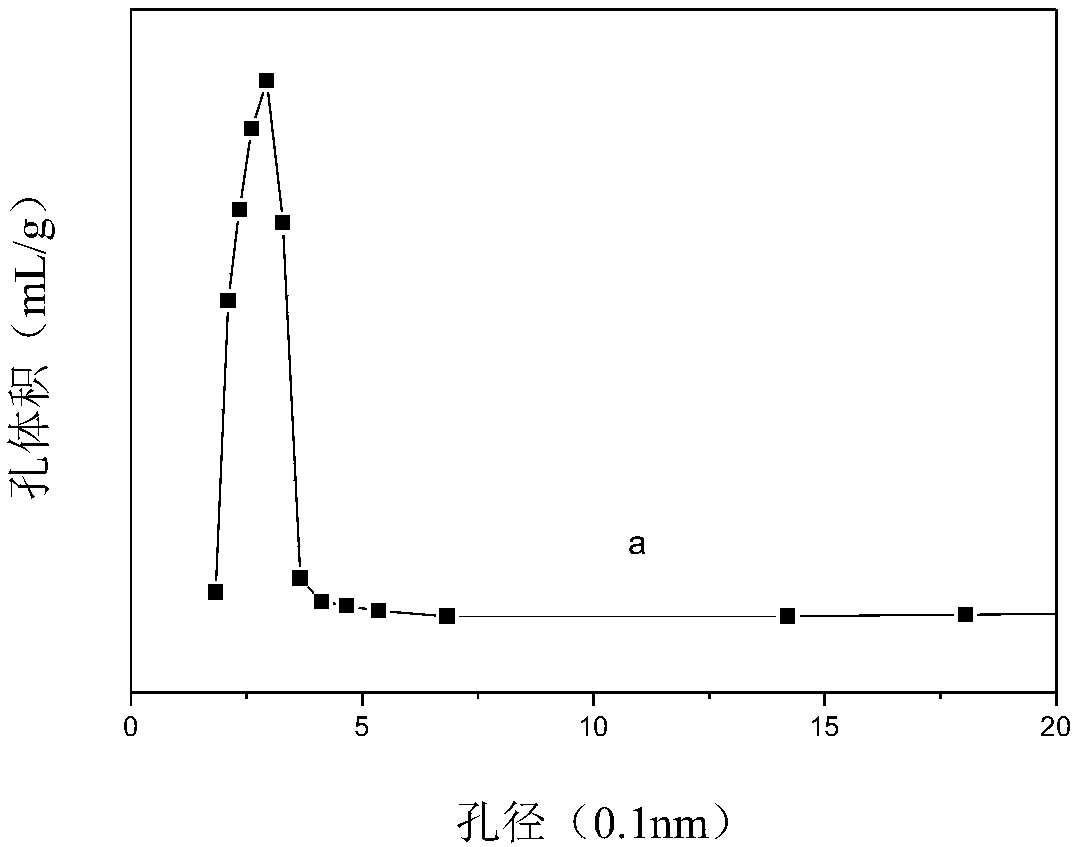

[0059] (1) Preparation of carrier

[0060]2.8 grams of phenol, 7.1 grams of 38% by weight formaldehyde solution and 69 grams of 0.1mol / L NaOH aqueous solution were successively added to a 250mL single-necked flask, heated and stirred at 72°C for 1.5 hours, and after dropping to 25°C, 6.72 grams of A mixed solution composed of P123 and 70 grams of deionized water, then heated the obtained mixture to 64°C, heated and stirred at 64°C for 120 hours, then raised the temperature to 72°C, stirred for 48 hours and then lowered to 25°C. The product was centrifuged to obtain a solid product, and the obtained solid product was dried in an oven at 80° C. for 4 hours; the dried solid product was raised from 25° C. to 350° C. at a rate of 1° C. per minute, and kept for 6 hours to obtain A mesoporous carbon material C1 with a cubic and hexagonal symbiotic pore structure of a cubic bo...

Embodiment 2

[0081] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

[0082] (1) Preparation of carrier

[0083] 2.8 grams of phenol, 23.7 grams of 38% by weight formaldehyde solution and 120 grams of 0.1mol / L NaOH aqueous solution were successively added to a 250mL single-necked flask, heated and stirred at 75°C for 2.5 hours, and after dropping to 25°C, 9.97g of A mixed solution composed of P123 and 70 grams of deionized water, then heated the obtained mixture to 60 ° C, heated and stirred at 60 ° C for 150 hours, then raised the temperature to 80 ° C, stirred for 36 hours and then lowered to 25 ° C, and the obtained reaction The product was centrifuged to obtain a solid product, and the obtained solid product was dried in an oven at 90° C. for 3.5 hours; the dried solid product was raised from 25° C. to 500° C. at a rate of 1° C. per minute, and kept for 4 hours to obtain A mesoporous carbon material C2 with a cubic and hexagonal symb...

Embodiment 3

[0091] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

[0092] (1) Preparation of carrier

[0093] 2.8 grams of phenol, 11.6 grams of 38% by weight formaldehyde solution and 90 grams of 0.1mol / L NaOH aqueous solution were successively added to a 250mL single-necked flask, heated and stirred at 70°C for 3 hours, and after dropping to 25°C, 13.3 grams of A mixed solution composed of P123 and 70 grams of deionized water, and the resulting mixture was heated to 65°C, heated and stirred at 65°C for 110 hours, then heated to 75°C, stirred for 40 hours and then lowered to 25°C, and the obtained reaction The product was centrifuged to obtain a solid product, and the obtained solid product was dried in an oven at 100° C. for 3 hours; the dried solid product was raised from 25° C. to 450° C. at a rate of 1° C. per minute, and kept for 5 hours to obtain A mesoporous carbon material C3 with a cubic and hexagonal symbiotic pore structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com