Composition and brightness enhancement film

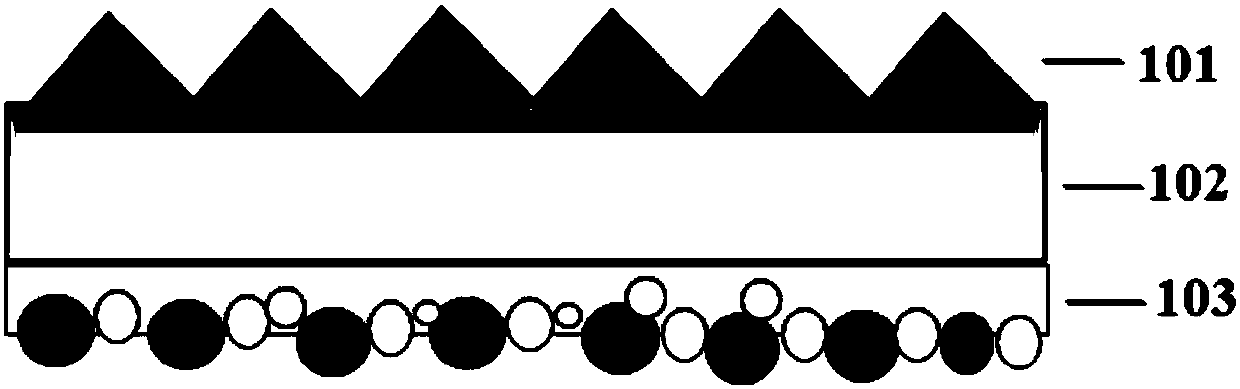

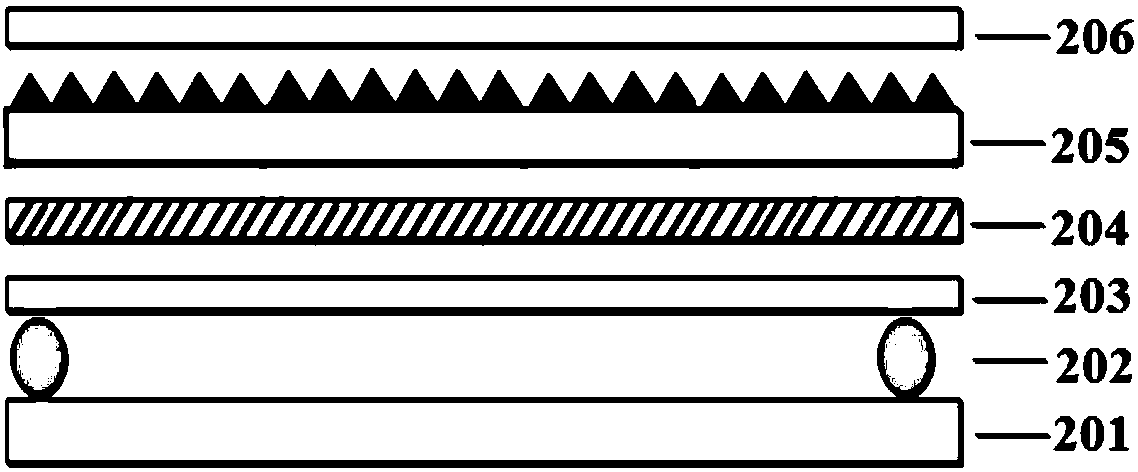

A technology of a composition and a brightness enhancement film, applied in the field of brightness enhancement film and composition, can solve the problems of insufficient brightness of the brightness enhancement film, unable to meet the energy saving of mobile display equipment, low refractive index, etc. Display the effect of energy saving of equipment, easy industrial production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

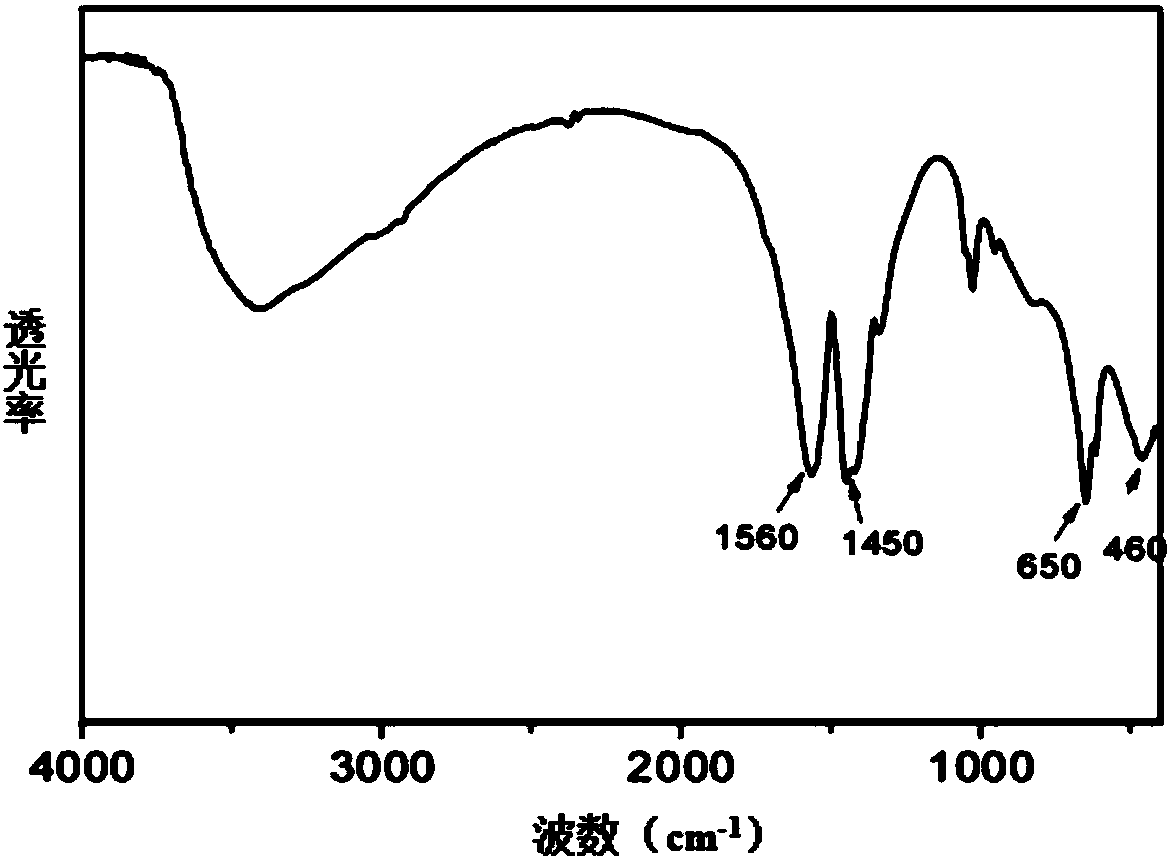

[0089] The preparation method of the zirconia particle provided by the invention comprises the following steps:

[0090] (1) Add the zirconium salt into absolute ethanol, stir and dissolve at room temperature, slowly add a mixed solution of deionized water, absolute ethanol and hydrochloric acid dropwise, the zirconium salt and deionized water undergo a hydrolysis reaction, and obtain zirconium alcohol and acid;

[0091] (2) Continue to stir at room temperature for 8-12 hours, and the zirconium alcohol undergoes self-condensation reaction to generate zirconia under the catalysis of hydrochloric acid and the acid generated by the hydrolysis reaction in step (1);

[0092] (3) The product obtained in step (2) is subjected to rotary distillation to remove small molecule products and residual deionized water to obtain zirconia particles.

[0093] The preparation method of composition provided by the invention comprises the steps:

[0094] (1) preparing zirconia particles;

[0095...

Embodiment 1

[0109] The invention provides a composition, the composition includes resin and zirconia particles, and the weight content of the zirconia particles is 48%.

[0110] The raw materials of the composition include the following components: zirconia particles: 48 parts by weight; photocurable resin: 20 parts by weight; photocurable monomer: 30 parts by weight; photoinitiator: 2 parts by weight; additives: 0.05 parts by weight ; Wherein the photocurable resin is a polyester acrylic resin; the photocurable monomer is o-phenylphenethoxyacrylate and pentaerythritol triacrylate, wherein o-phenylphenethoxyacrylate is 25 parts by weight, and pentaerythritol triacrylate 5 parts by weight; the photoinitiator is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO); the additives are leveling agent and defoamer, wherein the leveling agent is BYK- 3500, 0.03 parts by weight; wherein the defoamer is BYK-354, 0.02 parts by weight.

[0111] The above-mentioned raw material components were mixed...

Embodiment 2

[0121] As in the composition described in Example 1, the weight content of the zirconia particles is 20%.

[0122] The raw materials of the composition include the following components: zirconia particles: 20 parts by weight; photocurable resin: 36 parts by weight; photocurable monomer: 40 parts by weight; photoinitiator: 4 parts by weight; additives: 0.06 parts by weight . Wherein the light-curing resin is polyester acrylic resin; the light-curing monomer is biphenylmethanol acrylate and 2 (ethoxy) bisphenol A diacrylate, wherein biphenylmethanol acrylate is 20 parts by weight, 2 (ethoxy ) Bisphenol A diacrylate is 20 weight parts; Photoinitiator is 1-hydroxycyclohexyl phenyl ketone (184); , is 0.04 parts by weight; wherein the defoamer is selected from TEGO-900, which is 0.02 parts by weight.

[0123] The above-mentioned raw material components were mixed according to their parts by weight, dispersed at 800 r / min for 2 hours, and then filtered to obtain a composition.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com