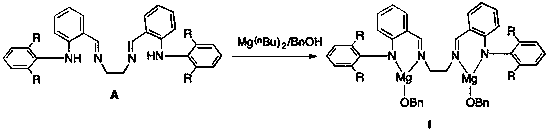

Method of utilizing dinuclear amine imine magnesium complex to catalyze lactide polymerization

A technology of dinuclear amine imine magnesium and complex is applied in the field of catalyzing lactide polymerization, can solve problems such as metal residue, and achieve the effects of low cost, high stereoselectivity and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]The structural formula of the ligand used is the above formula (A), where R is hydrogen, and the reaction process is as follows: under a nitrogen atmosphere, slowly add 5 mL of benzyl alcohol tetrahydrofuran solution (2.0 mol / L) to an equimolar amount of Mg( n Bu) 2 Hexane solution (2.0 mol / L, 5 mL) was reacted for 1 hour, 2.09 g of the ligand was dissolved in 20 mL of dry toluene, and added to Mg( n Bu) 2 In the reaction mixture with benzyl alcohol, after adding, the reaction liquid was naturally raised to room temperature, and then heated to 60 ° C for 3 hours. After the reaction was completed, the solvent was vacuum-dried, and the residue was washed with dry n-hexane, filtered, and then the product was collected and dried. Weighed to obtain 2.75 g of solid, yield 81.2%.

Embodiment 2

[0039] The structural formula of the ligand used is the above formula (A), where R is a methyl group, and the reaction process is as follows: under a nitrogen atmosphere, slowly add 5 mL of benzyl alcohol tetrahydrofuran solution (2.0 mol / L) to an equimolar amount of Mg( n Bu) 2 Hexane solution (2.0 mol / L, 5 mL) was reacted for 1 hour, 2.37 g of the ligand was dissolved in 20 mL of dry toluene, and added to Mg( n Bu) 2 and benzyl alcohol reaction mixture, after adding, the reaction liquid was naturally raised to room temperature, and then heated to 40 ° C for 12 hours, after the reaction was completed, the solvent was vacuum-dried, and the residue was washed with dry n-hexane, filtered, and then the product was collected and dried Weighed to obtain 3.27 g of solid, yield 89.1%.

Embodiment 3

[0041] The structural formula of the ligand used is the above formula (A), where R is ethyl, and the reaction process is as follows: under a nitrogen atmosphere, slowly add 5 mL of benzyl alcohol tetrahydrofuran solution (2.0 mol / L) to an equimolar amount of Mg( n Bu) 2 Hexane solution (2.0 mol / L, 5 mL) was reacted for 1 hour, 2.65 g of the ligand was dissolved in 30 mL of dry toluene, and added to Mg( n Bu) 2 In the reaction mixture with benzyl alcohol, after adding, the reaction liquid was naturally raised to room temperature, and then heated to 50 ° C for 4 hours. After the reaction was completed, the solvent was vacuum-dried, and the residue was washed with dry n-hexane, filtered, and then the product was collected and dried. Weighed to obtain 3.17 g of solid, yield 80.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com