Poly-alpha-olefin synthetic lubricant base oil preparation method

A technology for synthesizing lubricating oil and base oil, applied in the directions of lubricating compositions, chemical instruments and methods, base materials, etc., can solve the problem of less effective components of lubricating oil base oil, avoid the rapid rise of reaction temperature and improve yield. rate, mild effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

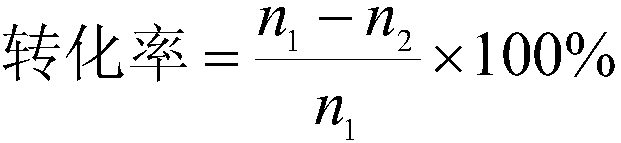

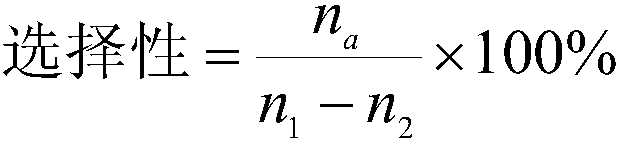

[0087] Build the reaction device and ensure that the reaction system is airtight, and replace the air in the reaction system with nitrogen three times to ensure that the reaction is carried out in an anhydrous and oxygen-free environment. Take 20mL of 1-hexene and place it in a constant-pressure dropping funnel, add 0.5mL of 0.015mol / L bis(tetramethylcyclopentadiene) zirconium dichloride / toluene solution and 2mL of 1.5mol / L MAO / The toluene solution (the molar ratio of the aluminum in the cocatalyst to the zirconium in the main catalyst is 400) was added into the reaction kettle, and the temperature was gradually raised to 60° C. after being uniformly stirred by magnetic force and kept there. Utilize the constant pressure dropping funnel dropwise to add 20mL 1-hexene (the molar ratio of reactant and main catalyst is 2.13×10 4 ) into the reaction kettle, the rate of addition is controlled to be about 0.4mL / min, the temperature of the reaction system is controlled to be 60° C. b...

Embodiment 2

[0089] Same as Example 1, except that 20 mL of 1-hexene is added in one go. See Table 1 for the data.

Embodiment 3

[0091] Same as Example 1, except that the reaction temperature used is 50°C. See Table 1 for the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com