Preparation method and application of boron nitride/polyoxyethylene composite solid electrolyte

A solid electrolyte, polyethylene oxide technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problem of not using lithium metal batteries, and achieve the effect of uniform solid electrolyte membrane, mild conditions, and good encapsulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

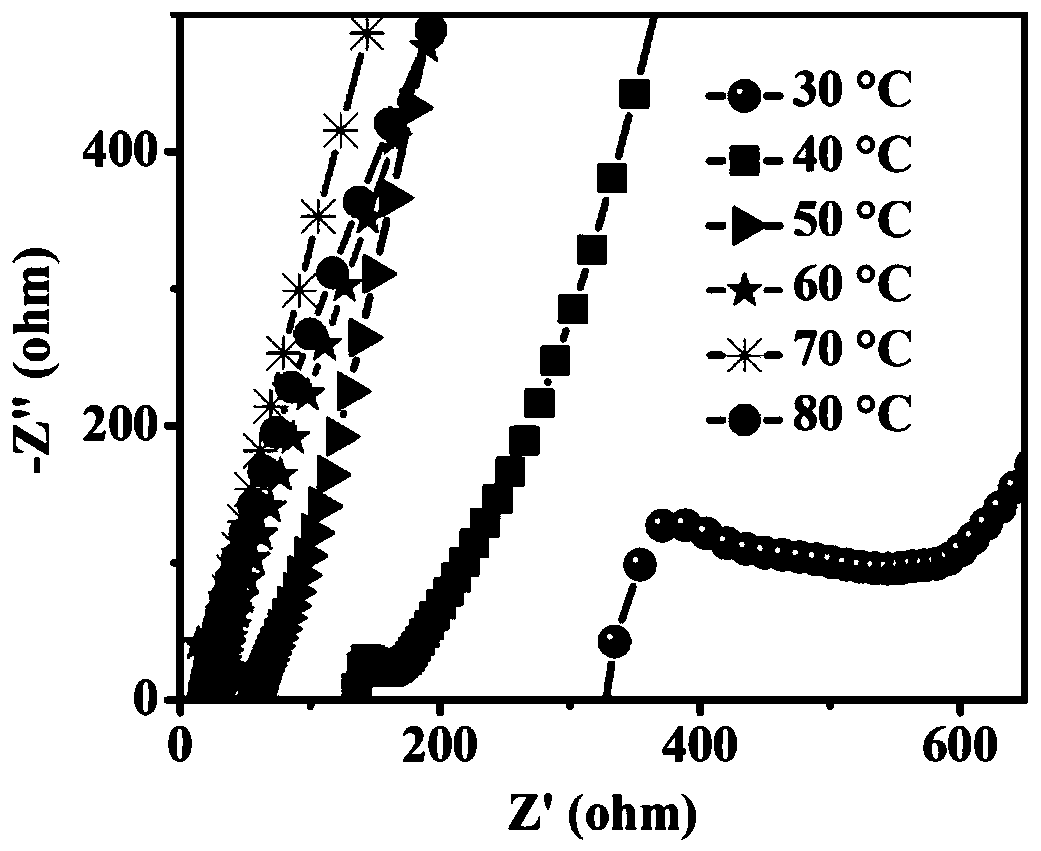

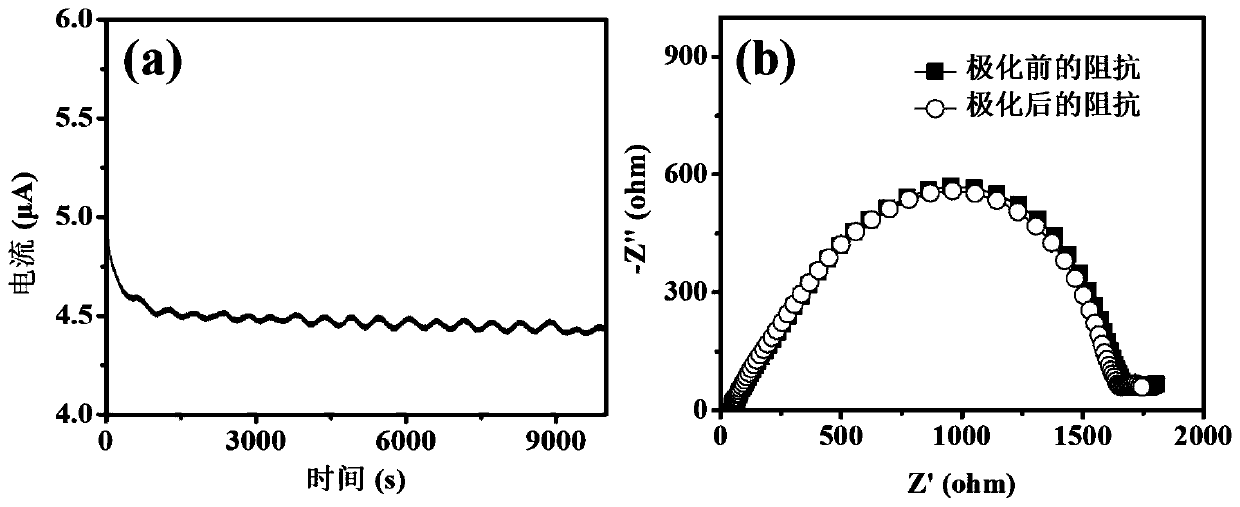

Examples

Embodiment 1

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] (1) Put 0.6g of nano-boron nitride into a 500mL round bottom flask, add 200mL of acetonitrile into it, put it into an ultrasonic cleaner with a power of 40W, and perform ultrasonication for 6 hours to obtain a boron nitride-acetonitrile dispersion , add 10g of polyethylene oxide (referred to as: PEO) in the dispersion, magnetically stirred for 1 hour to form a uniformly mixed emulsion; nano-boron nitride is a nano-sheet with a diameter of 50-1000nm and a thickness of 10-100nm;

[0031] (2) Add 1 g of lithium bistrifluoromethanesulfonimide (abbreviation: LiTFSI) to the mixed emulsion in step 1, and stir with a magnetic stirrer for 1 hour to obtain a mixed solution;

[0032] (3) Slowly pour the mixed solution prepared in step 2 into a polytetrafluoroethylene mold, place it in a fume hood, and wait for the acetonitrile to evaporate to form a polymer solid electrolyte membrane. Place i...

Embodiment 2

[0039] The preparation method of the present embodiment comprises the following steps:

[0040] (1) Put 0.3g of nano-boron nitride into a 500mL round-bottomed flask, add 300mL of acetonitrile into it, put it into an ultrasonic cleaner with a power of 40W, and perform ultrasonication for 1 hour to obtain a boron nitride-acetonitrile dispersion , add 10g of polyethylene oxide (referred to as: PEO) in the dispersion, magnetically stirred for 1 hour to form a uniformly mixed emulsion; nano-boron nitride is a nano-sheet with a diameter of 50-1000nm and a thickness of 10-100nm;

[0041] (2) Add 0.7 g of lithium bistrifluoromethanesulfonimide (abbreviation: LiTFSI) to the mixed emulsion in step 1, and stir with a magnetic stirrer for 1 hour to obtain a mixed solution;

[0042] (3) Slowly pour the mixed solution prepared in step 2 into a polytetrafluoroethylene mold, place it in a fume hood, wait for the acetonitrile to evaporate, and form a polymer solid electrolyte membrane; place i...

Embodiment 3

[0046] The preparation method of the present embodiment comprises the following steps:

[0047] (1) Put 0.9g of nano-boron nitride into a 500mL round bottom flask, add 250mL of methanol into it, put it into an ultrasonic cleaner with a power of 40W, and perform ultrasonication for 3 hours to obtain a boron nitride-acetonitrile dispersion , add 10g polyethylene oxide (referred to as: PEO) to the dispersion liquid, magnetically stir for 1 hour to form a uniformly mixed emulsion; nano-boron nitride is boron nitride in the form of an array with a diameter range of 10-30 μm and a thickness of 0.1-1 μm;

[0048] (2) Add 1.5 g of lithium bistrifluoromethanesulfonimide (abbreviation: LiTFSI) to the mixed emulsion in step 1, and stir with a magnetic stirrer for 1 hour to obtain a mixed solution;

[0049] (3) Slowly pour the mixed solution prepared in step 2 into a polytetrafluoroethylene mold, place it in a fume hood, wait for the methanol to evaporate, and form a polymer solid electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com