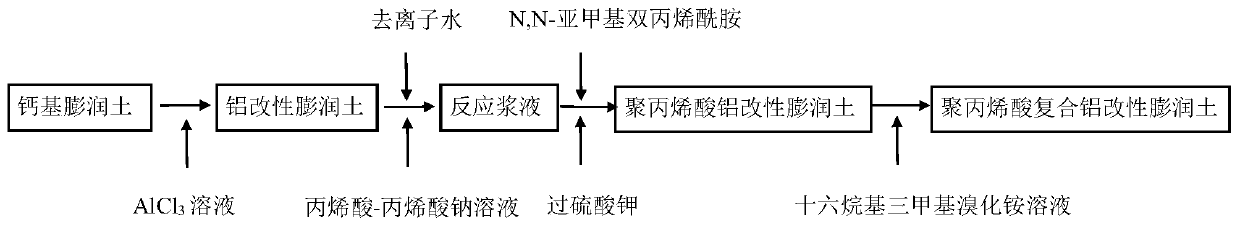

Preparation method of polyacrylic acid composite aluminum modified bentonite water treatment agent capable of absorbing Cr (VI)

A technology of aluminum polyacrylate and water treatment agent, which is applied in the fields of adsorption water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of small adsorption amount of chromium anions and difficult solid-liquid separation, etc. Achieve the effect of easy solid-liquid separation, abundant resources, and increased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

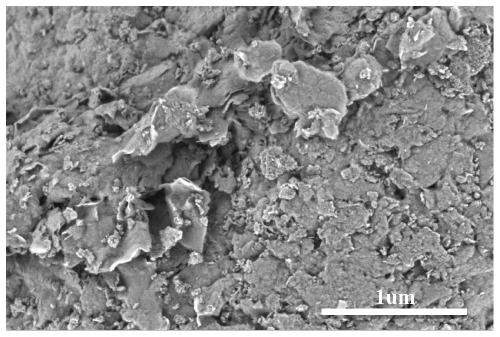

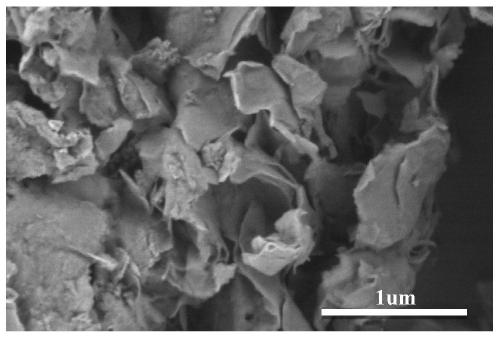

Image

Examples

Embodiment 1

[0030] Embodiment 1: the specific operations are as follows

[0031] (1) The natural calcium-based bentonite is purified by a wet purification method, ground and sieved with 200 mesh (75 μm) for subsequent use;

[0032] (2) Configure AlCl with a mass concentration of 10g / L 3 Solution, the purified calcium-based bentonite and AlCl 3 The solutions were mixed, stirred electrically at room temperature for 2 hours, left to stand overnight, suction filtered, and dried to obtain aluminum-modified bentonite, which was ground and passed through a 200-mesh (75 μm) sieve for later use;

[0033] Wherein, the mass ratio is calcium-based bentonite: AlCl 3 Solution = 1:10;

[0034] (3) Configure an aqueous solution of acrylic acid with a volume fraction concentration of 50%, add an appropriate amount of NaOH for neutralization, and configure an acrylic acid-sodium acrylate solution with a neutralization degree of 20%;

[0035] (4) Mix aluminum-modified bentonite, acrylic acid-sodium acry...

Embodiment 2

[0042] Embodiment 2: specific operation is as follows

[0043] (1) The natural calcium-based bentonite is purified by a wet purification method, ground and sieved with 200 mesh (75 μm) for subsequent use;

[0044] (2) Configure AlCl with a mass concentration of 10g / L 3 Solution, the purified calcium-based bentonite, AlCl 3 The solutions were mixed, stirred electrically at room temperature for 2 hours, left to stand overnight, suction filtered, and dried to obtain aluminum-modified bentonite, which was ground and passed through a 200-mesh (75 μm) sieve for later use;

[0045] Among them, the mass ratio is calcium-based bentonite: AlCl 3 Solution = 1:10;

[0046] (3) Configure an aqueous solution of acrylic acid with a volume fraction concentration of 50%, add an appropriate amount of NaOH for neutralization, and configure an acrylic acid-sodium acrylate solution with a neutralization degree of 20%;

[0047] (4) Mix aluminum-modified bentonite, acrylic acid-sodium acrylate s...

Embodiment 3

[0054] Embodiment 3: specific operations are as follows

[0055] (1) The natural calcium-based bentonite is purified by a wet purification method, ground and sieved with 200 mesh (75 μm) for subsequent use;

[0056] (2) Configure AlCl with a mass concentration of 10g / L 3 Solution, the purified calcium-based bentonite, AlCl 3 The solutions were mixed, stirred electrically at room temperature for 2 hours, left to stand overnight, suction filtered, and dried to obtain aluminum-modified bentonite, which was ground and passed through a 200-mesh (75 μm) sieve for later use;

[0057] Among them, the mass ratio is calcium-based bentonite: AlCl 3 Solution = 1:10;

[0058] (3) Configure an aqueous solution of acrylic acid with a volume fraction concentration of 50%, add an appropriate amount of NaOH for neutralization, and configure an acrylic acid-sodium acrylate solution with a neutralization degree of 20%;

[0059] (4) Mix aluminum-modified bentonite, acrylic acid-sodium acrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equilibrium adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap