Preparation method of super light foam concrete waterproof coating and obtained super light foam concrete with ultralow water absorption rate

A foamed concrete and waterproof coating technology is applied in the fields of improving the waterproofness of ultra-light foam concrete, preparation of ultra-light foam concrete waterproof coating, and ultra-low water absorption and ultra-light foam concrete, which can solve the problem of increased thermal conductivity and thermal insulation effect. problems such as decrease and increase in water absorption rate, to achieve the effect of reducing mass water absorption rate, reducing water absorption rate, and reducing volume water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Applying a waterproof coating on the surface of ultra-light foam concrete includes the following steps:

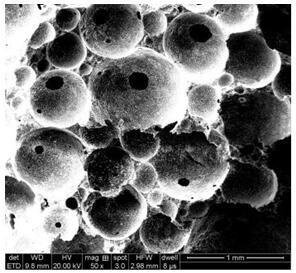

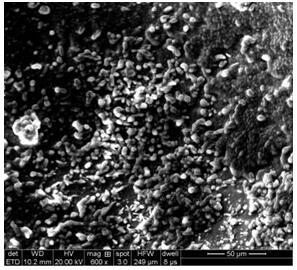

[0053] Step 1: Prepare ultra-light foam concrete: use a single sulphoaluminate cement as the cementitious material, first add mixing water (water-cement ratio 0.4-0.43) and stir for 3 minutes to form a cement slurry; add prefabricated cement to the cement slurry Foam (foam accounts for 30-40% of the cement mass, and the foam density is 72 kg / m3) is stirred for 3 minutes to form a foamed cement paste; the foamed cement paste is molded and cured at 25 °C, and the mold is removed after 1 day , and then moved to a foam box for 7 days of curing at 25 °C, taken out, dried at 60 °C to constant weight, and cooled to room temperature to obtain ultra-light foam concrete. The porosity is detected by ZEISS Xradia 510 Versa nano-CT, the total porosity is 89.2%, and the dry density is ≤300 kg / m 3 . The microscopic morphology of ultra-light foamed concrete cells is as follows: ...

Embodiment 2

[0062] Step 1: prepare ultra-light foam concrete: same as embodiment 1.

[0063] Step 2: Cut the test block into small rectangular parallelepiped pieces of 5 cm×4 cm×3 cm with a carving knife, gently brush off the shedding on the surface of the sample with a small brush, and weigh the mass of the sample with an analytical balance.

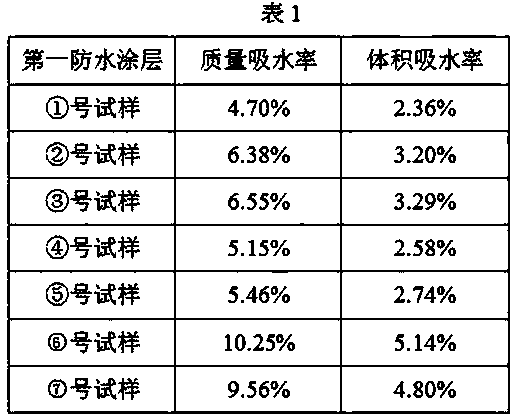

[0064] Step 3: Apply the first waterproof coating: Same as Example 1, the difference is that the first waterproof layer solution uses the following samples respectively: No. ① sample: 5.3 mL of 5‰ polyacrylamide aqueous solution, hexadecyl Trimethoxysilane 4.0mL, nano-silica dispersion 10.7mL; No. 2 sample: 5.7mL 5‰ polyacrylamide aqueous solution, hexadecyltrimethoxysilane 3.0mL, nano-silica dispersion 11.3mL; Sample ③: 3.1mL 5‰ polyacrylamide aqueous solution, 4.5mL hexadecyltrimethoxysilane, 12.4mL nano-silica dispersion; sample ④: 5.3mL 7‰ polyacrylamide aqueous solution, Alkyltrimethoxysilane 4.0mL, nano-silica dispersion 10.7mL; No. ⑤ sample...

Embodiment 3

[0071] Step 1: prepare ultra-light foam concrete: same as embodiment 1.

[0072] Step 2: Cut the test block into small rectangular parallelepiped pieces of 5 cm×4 cm×3 cm with a carving knife, gently brush off the shedding on the surface of the sample with a small brush, and weigh the mass of the sample with an analytical balance.

[0073] Step 3: Apply the first waterproof coating: Same as in Example 1.

[0074] Step 4: Brush the second waterproof coating: Same as Example 1, the difference is that the second waterproof layer solution uses the following samples respectively: No. ① sample: hexadecyltrimethoxysilane 10.0mL, nanometer two Silica dispersion 10.0mL; No. ② sample: 6.7 mL hexadecyltrimethoxysilane, 13.3 mL nano-silica dispersion; ③ No. sample: 5.0 mL hexadecyl trimethoxysilane, nanometer silica Silica dispersion 15.0mL; sample ④: hexadecyltrimethoxysilane 4.0mL, nano-silica dispersion 16.0mL; sample ⑤: hexadecyltrimethoxysilane 3.3mL, nano-silica Silicon oxide disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com