Cell carrier particle aggregate and preparation method thereof

A technology of carrier particles and aggregates, applied in general culture methods, biochemical equipment and methods, fixed on/in organic carriers, etc., can solve problems such as difficulty in use, reduction of effective mass, and splashing of microcarrier powder. Achieve beautiful and convenient use, facilitate aseptic operation, and avoid static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1, stamping aggregate molding

[0065] The stamping and gathering forming machine is an automatic stamping and gathering forming machine, and the motor rocker rotates one week to produce a finished product. The stamping and aggregation molding machine is fixed and quantitative by the method of measuring volume.

[0066] First weigh 20 mg of cell carrier particles on a balance, then pour the weighed material into the feeding place of the stamping molding machine, and select an inclined flat punching mold. Adjust the upper punch of the stamping aggregation forming machine, the adjustment range is 0-50mm, and adjust the lower punch of the stamping aggregation molding machine, the adjustment range is 0-50mm. Run the handle of the stamping and gathering molding machine to fill the material, adjust the pressure value, the pressure value can be controlled within the range of 0-200KN, turn on the motor, and shake the rocker of the motor for one week to complete a st...

Embodiment 2

[0077] Embodiment 2, mold forming

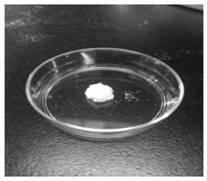

[0078] Take a certain amount of powdered cell carrier particles, add deionized water (the amount added is 50 times the weight of the cell microcarriers), and use auxiliary tools to make it evenly and evenly cover the mold. The mold is cylindrical (can also be circular, square, rhombus, triangle, ellipse, polygon and polygon, etc.). A mold containing a certain mass of cell carrier particles (such as Figure 8 (shown) placed in an oven at 60°C and dried continuously for 96 hours to obtain solid and stable aggregates of cell carrier particles with the same unit mass and shape, as shown in Figure 9 shown.

[0079] Put the cell carrier particle aggregate prepared in this example into water, and it can be quickly dispersed into the state of individual cell carrier particles, such as Figure 10 As shown, the results show that there is no change in its shape and physical properties.

[0080] The cell carrier particle aggregates prepared in this...

Embodiment 3

[0083] Embodiment 3, lyophilization and drying molding

[0084] Take a certain amount of powdered microcarriers, add deionized water (the amount added is 100 times the weight of the cell microcarriers), and use auxiliary tools to make them aggregate into regular shaped blocks, such as Figure 11 As shown; put the aggregates into a freezing container, and form a block-shaped frozen body during the low-temperature freezing process at 0 to -196 ° C; put the frozen aggregates into a freeze dryer, freeze-dry for 96 hours, and take them out After that, freeze-dried aggregates were formed, such as Figure 12 shown.

[0085] The cell carrier particle aggregates prepared in this example can be quickly dispersed into the state of individual microcarrier particles, such as Figure 13 As shown, the results show that there is no change in its shape and physical properties.

[0086] The cell carrier particle aggregates prepared in this example have the property of quickly absorbing water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com