Preparation process of lightweight double-glazed module with frame

A technology of double-glass components and preparation process, which is applied in the direction of sustainable manufacturing/processing, electrical components, semiconductor devices, etc., can solve the problems of poor durability, heavy weight, and easy aging of rubber skin, and achieve high light transmittance and low density , Improve the effect of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

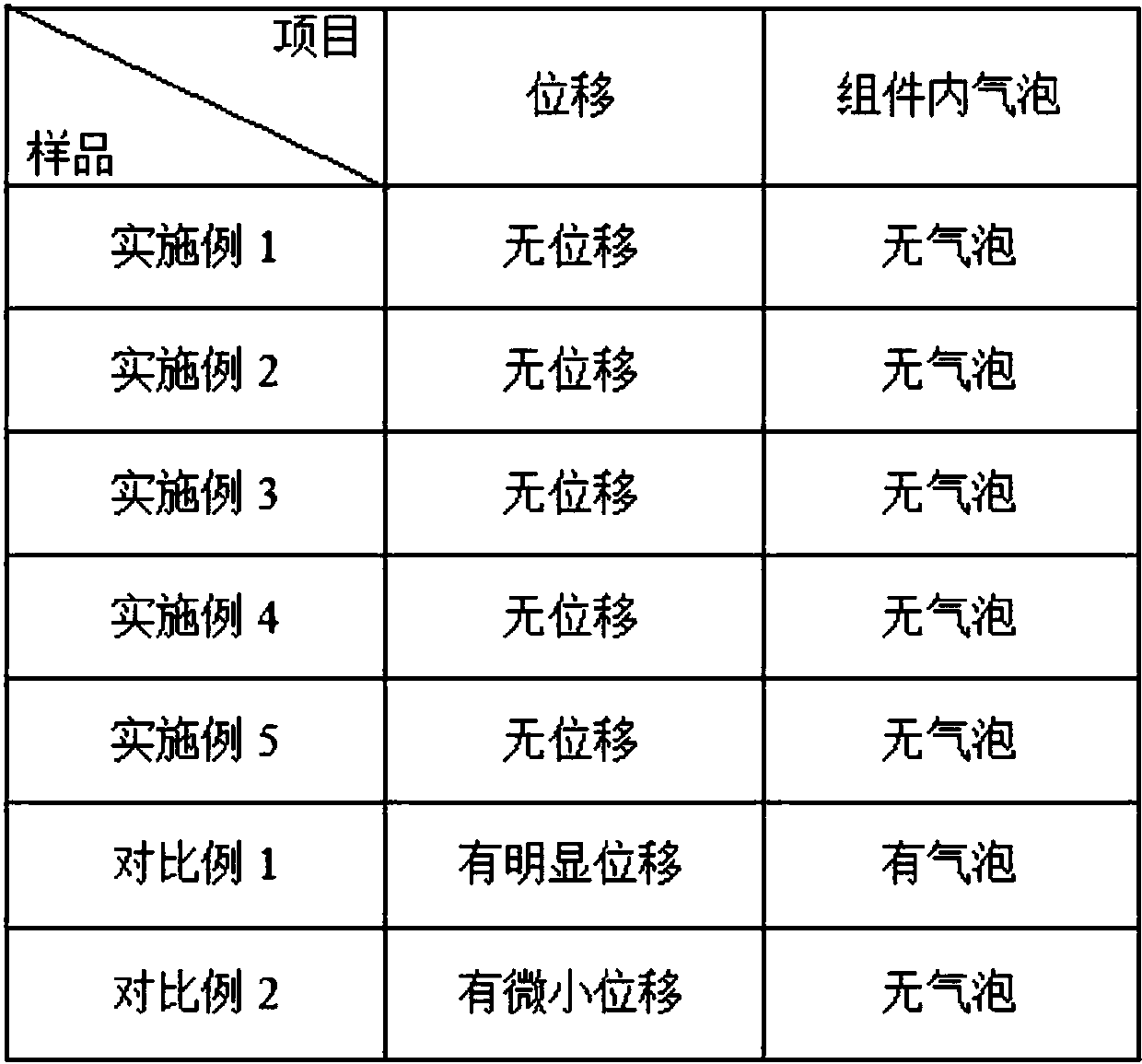

Examples

Embodiment 1

[0046] A preparation process for a lightweight framed double-glass component, the preparation process comprising the following steps:

[0047] (1) Mix 100 parts of ethylene-vinyl acetate, 1 part of 2,4-dihydroxybenzophenone, 1 part of 1-butyl-3-methylimidazolium chloride salt, 0.5 parts of sodium polymethacrylate and 0.1 parts Put the coupling agent into the mixer and mix evenly. The coupling agent is a mixture of silane coupling agents KH-57, Z-6032 and KH-550 with a mass ratio of 1:1:1, and then pass through the internal mixer at 120 ° C. Extrude after melting and mixing, and the extruded product is cast, cooled, drawn, and rolled to form a film to obtain a high-transmittance EVA film;

[0048] (2) On the bottom ultra-clear embossed tempered glass, lay the high light-transmitting EVA adhesive film prepared in step (1), the solar cell string, the high light-transmitting EVA adhesive film prepared in step (1), The surface layer of ultra-clear semi-tempered glass forms a solar...

Embodiment 2

[0055] A preparation process for a lightweight framed double-glass component, the preparation process comprising the following steps:

[0056] (1) 110 parts of ethylene-vinyl acetate, 1.5 parts of 2-hydroxy-4-dodecyloxybenzophenone, 1.2 parts of 1-butyl-3-methylimidazole trifluoromethanesulfonate, 0.6 Part of methyl cellulose and 0.2 part of coupling agent are put into the mixer and mixed evenly, the coupling agent is a mixture of silane coupling agents KH-57, Z-6032 and KH-550 with a mass ratio of 2:2:1, Then it is melted and mixed at 130°C by an internal mixer and then extruded, and the extruded product is cast, cooled, drawn, and rolled to form a film to obtain a high-transmittance EVA film;

[0057] (2) On the bottom ultra-clear embossed tempered glass, lay the high light-transmitting EVA adhesive film prepared in step (1), the solar cell string, the high light-transmitting EVA adhesive film prepared in step (1), The surface layer of ultra-clear semi-tempered glass forms ...

Embodiment 3

[0064] A preparation process for a lightweight framed double-glass component, the preparation process comprising the following steps:

[0065] (1) 125 parts of ethylene-vinyl acetate, 2 parts of 2-hydroxy-4-methoxy-5-sulfobenzophenone, 1.5 parts of 1-allyl-3-methylimidazolium chloride, 0.75 One part of sodium tripolyphosphate and 0.3 part of coupling agent are put into the mixer and mixed evenly. The coupling agent is a mixture of silane coupling agents KH-57, Z-6032 and KH-550 with a mass ratio of 2:2:1. Then it is extruded after being melted and mixed at 135°C by an internal mixer, and the extruded product is cast, cooled, drawn, and rolled to form a film to obtain a high-transmittance EVA film;

[0066] (2) On the bottom ultra-clear embossed tempered glass, lay the high light-transmitting EVA adhesive film prepared in step (1), the solar cell string, the high light-transmitting EVA adhesive film prepared in step (1), The surface layer of ultra-clear semi-tempered glass for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com