A kind of preparation method and application of less fluorine porous titanium carbide Miconene

A technology of titanium carbide miconene and hydrofluoric acid, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as poor safety, low Coulombic efficiency, and poor cycle stability, and achieve low cost, easy operation, and high performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

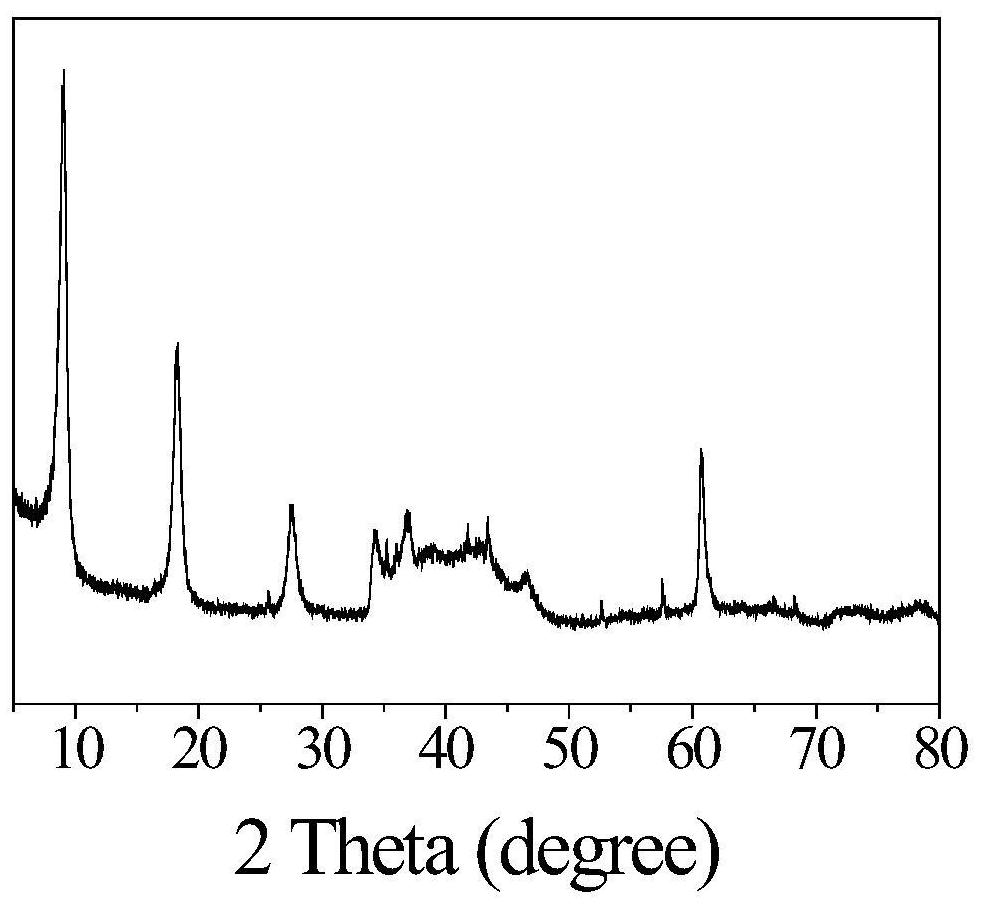

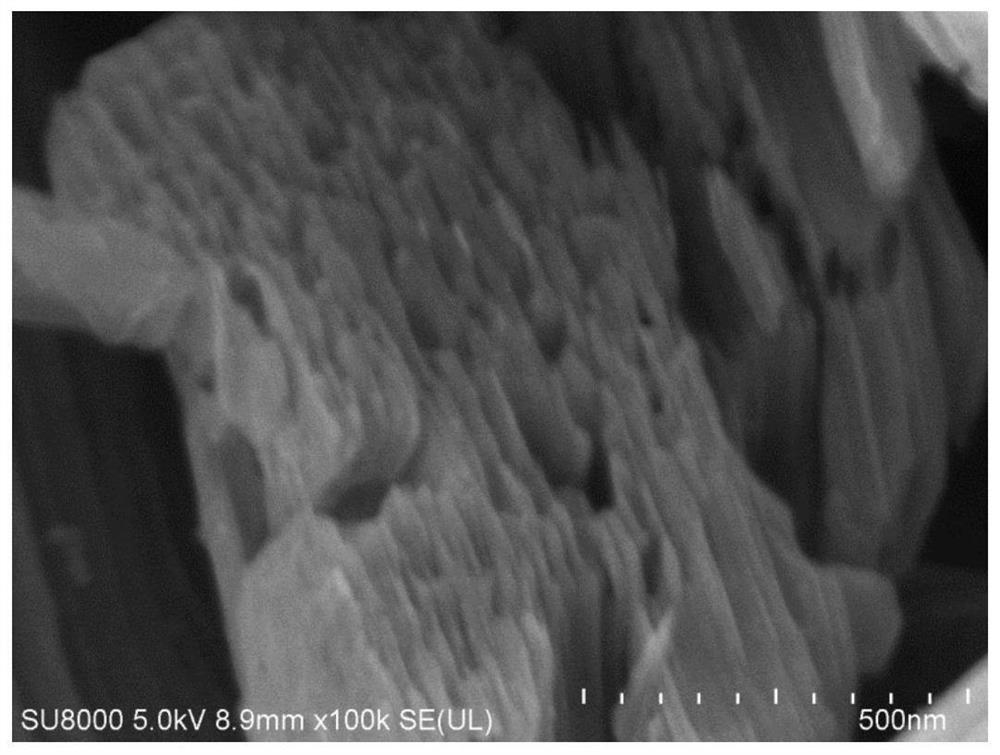

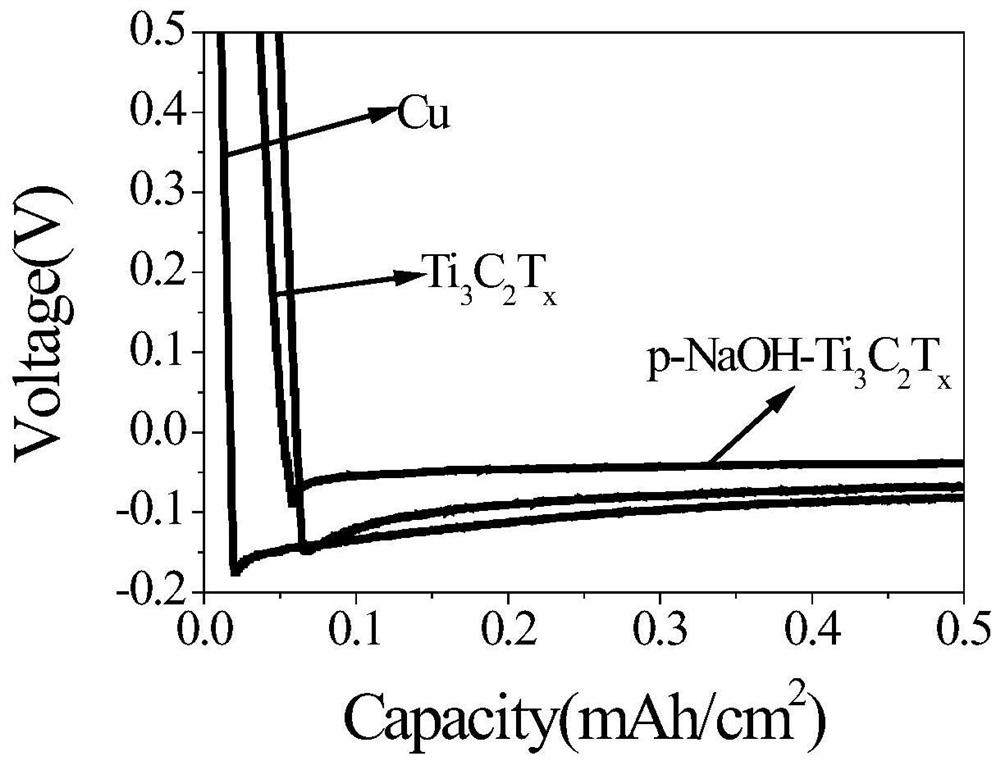

[0021] A preparation method of less fluorine porous titanium carbide Micone, comprising the following steps:

[0022] 1) Put 2gTi 3 AlC 2 Dissolve in 35 ml of concentrated hydrofluoric acid (mass concentration 37%), stir magnetically for 2 days, ultrasonically clean 3 times with deionized water and ethanol, and then dry at 60°C to obtain powder A;

[0023] 2) Disperse the above powder A into 75ml of 10M sodium hydroxide solution, stir magnetically for 2 hours, ultrasonically clean with deionized water and ethanol for 3 times, and then dry at 60°C to obtain powder B;

[0024] 3) Disperse the above powder B in 30ml deionized water to obtain a solution, transfer the solution to a stainless steel autoclave lined with polytetrafluoroethylene, and place the autoclave in a constant temperature drying oven at 175°C for 18 hours , and then ultrasonically cleaned three times with deionized water and ethanol, and finally dried at 60°C to obtain powder C;

[0025] 4) Disperse the above...

Embodiment 2

[0029] A preparation method of less fluorine porous titanium carbide Micone, comprising the following steps:

[0030] 1) Put 1gTi 3 AlC 2 Dissolve in 20ml of concentrated hydrofluoric acid (mass concentration 35%), stir magnetically for 1 day, ultrasonically clean 3 times with deionized water and ethanol, and then dry at 5°C to obtain powder A;

[0031] 2) Disperse the above powder A into 50ml of 5M sodium hydroxide solution, stir magnetically for 1 hour, ultrasonically clean with deionized water and ethanol for 3 times, and then dry at 55°C to obtain powder B;

[0032]3) Disperse the above powder B in 20ml of deionized water to obtain a solution, transfer the solution to a stainless steel autoclave lined with polytetrafluoroethylene, and place the autoclave in a constant temperature drying oven at 150°C for 20 hours , and then ultrasonically cleaned three times with deionized water and ethanol, and finally dried at 55°C to obtain powder C;

[0033] 4) Disperse the above po...

Embodiment 3

[0036] A preparation method of less fluorine porous titanium carbide Micone, comprising the following steps:

[0037] 1) Add 3gTi 3 AlC 2 Dissolve in 50 ml of concentrated hydrofluoric acid (mass concentration 40%), stir magnetically for 1-3 days, ultrasonically clean 4 times with deionized water and ethanol, and then dry at 65°C to obtain powder A;

[0038] 2) Disperse the above powder A into 100ml of 15M sodium hydroxide solution, stir it magnetically for 1-3 hours, ultrasonically clean it with deionized water and ethanol for 4 times, and then dry it at 65°C to obtain powder B;

[0039] 3) Disperse the above powder B in 40ml of deionized water to obtain a solution, transfer the solution to a stainless steel high-pressure reactor lined with polytetrafluoroethylene, and place the reactor in a constant temperature drying oven at 200°C for 16 hours , and then ultrasonically cleaned four times with deionized water and ethanol, and finally dried at 65°C to obtain powder C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com