Copper-based catalyst as well as manufacture method and application thereof

A technology of copper-based catalysts and manufacturing methods, applied in the fields of carbon-based compound preparation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

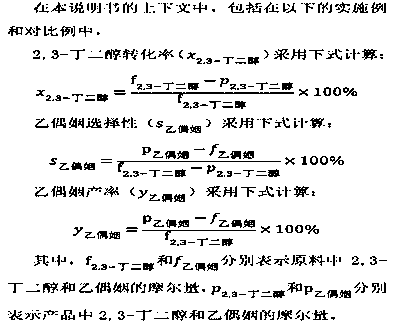

[0139] According to an embodiment of the present invention, the step (2-1) may include the step (2-1-1).

[0140] Step (2-1-1): under the conditions of temperature 100-200° C. and pressure 0.1-5 MPa, contact the ketone compound represented by the formula (II) with the catalyst precursor for 2-60 hours.

[0141] According to one embodiment of the present invention, in the step (2-1-1), there is no particular limitation on the method of contacting the ketone compound represented by the formula (II) with the catalyst precursor, specifically For example, it can be mentioned that the ketone compound represented by the formula (II) is contacted with the catalyst precursor in the form of a gaseous state or a gas mixture, or specifically such as making the ketone compound represented by the formula (II) The ketones are adsorbed by the catalyst precursor in gaseous state or gas mixture until a predetermined content is reached.

[0142] According to one embodiment of the present invent...

Embodiment 1

[0227] The preparation method of copper-based catalyst H1 is as follows:

[0228] (1-1) Weigh 122 g of copper nitrate, 103 g of ytterbium nitrate and 88 g of aluminum nitrate respectively, dissolve them in 1 L of deionized water, and prepare solution A1. Weigh 16 g of potassium hydroxide and 24 g of potassium bicarbonate respectively, dissolve them in 1L of deionized water, and configure solution B1. Add 1L of deionized water into a 5L beaker, raise the temperature and maintain it at 75°C, add solutions A1 and B1 dropwise at the same time under the condition of continuous stirring, control the pH value to maintain around 8.0, and continue stirring for 2 h after the dropwise addition is completed , followed by static aging for 2 h, and filtered to obtain precipitate C1.

[0229] (1-2) Dry the precipitate C1 at 110°C for 24 hours, then bake it at 400°C for 5 hours, then add graphite powder with 3% weight of the precipitate as a lubricant, press into tablets, and then bake at 40...

Embodiment 2

[0234] The preparation method of copper-based catalyst H2 is as follows:

[0235] (1) Using the catalyst H1 prepared in Example 1 as the catalyst precursor;

[0236] (2) Grind the above catalyst precursor H1 into powder, add the H1 powder into the straight sample tube of TP-5082 chemical adsorption instrument, raise the temperature to 100°C under nitrogen atmosphere, and switch to the volume fraction of acetoin It is 1% acetoin / nitrogen mixed gas, the treatment time is 48 hours, and the temperature is lowered to take out as catalyst H2.

[0237] Through element analysis, the weight content of CuO of catalyst H2 is 40.1%, Yb 2 o 3 The weight content is 44.0%, K 2 The weight content of O is 2.6%, Al 2 o 3 The weight content of acetoin is 12.1%, and the weight content of acetoin is 1.2%.

[0238] Before the catalyst H2 is used for the reaction of glycol dehydrogenation to prepare hydroxy ketones, the following steps are used for pretreatment:

[0239] (3-1) Weigh 10 g of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com